Dan wrote:

Quite interesting contents, though unfortunately filmed for those people having one eye located above the other, iso of the horizontal eye location, next to each other, more commonly found in the human species.

Wow – I’ll wait for the widescreen version without the motion. :) No way I’m watching that for over an hour!

Let me take a step back

Vans has been selling kits for over 40 years. The laser cut holes “scandal” is not the first PR crises the company is going through. Back in the dark ages RVs would disintegrate in flight, people got killed. Dick himself was writing letters to the FAA explaining what had happened and describing how the problem was addressed. In our times there ware also tragic cases, like the one where a horizontal stabiliser disintegrated in flight. Again, the company was on top of the problem. I can’t remember Vans trying to sweep problems under the rug. Ever.

Compare that to what happened after the DR400 disintegrated in the air killing family of 4. The poor chap flying the plane was accused of performing aerobatics, meaning they accused him of killing his family. At the time the manufacturer didn’t come forward admitting that since 1973 each and every one of their aircraft was improperly glued. How many years until the AD came to force? (I do know a thing or two on the subject)

Coming back to Euroga: we read opinions here regarding which RV design in more “proven” with majority of flaws ironed out. Same “experts” make strong judgments on the technology of aircraft kit manufacturing. How does one make such claims with no academic background, no professional work experience and in my opinion questionable knowledge? By repeating and rephrasing what someone else posted somewhere on the internet.

In my opinion Vans (till today) did exactly as they did in the past 40 years, they are addressing the problem, analysing it and communicating the affected parties. The video in question is an example of such communication. I’m surprised that anyone changed his mind after watching this, as it’s clearly the case.

Can you give me the source of Robin having admitted they have been using the wrong glue since 1973?

Certainly Robin have twice now had a glue problem. The first I recall was in the 1990’s the second I believe was either this year or last.

Robin did recalls and worked with the French clubs ( the main market for Robin aircraft)to find a solution, acceptable to the majority of their customers, which they did in the first case. And AIUI they were in the process of doing in the 2nd case.

That being said, in the first case it lead to Robin Aircraft’s liquidation and eventually a rebirth with the spltting of both manufacture and parts. And with a great deal of help and pressure from clubs and the FFA.

They never fully recovered and have just been bailed out again probably with the help of.M. Macron.

IMO I doubt of they will ever be the company they were because of posts like @RV14 has just posted. Hence the court of public opinion.

They may be able to recover to a bespoke aircraft manufacturer, but who knows.

Here is the root cause of the problem, according to Van’s, as explained in that video

The correct way to cut is to use a path that goes like this:

Cutting of the actual hole is done in a continuous fashion, and very fast, and with gas injected as well. The heat up of the material is minimal.

The wrong way, but which was done on some parts due to miscommunication, or lack of communication? was this:

When the laser goes down to the S position, it will stop for some microseconds before starting to cut. Those microseconds is enough to heat up the material in a larger zone, and it that sone the crack may occur.

Crack and fatigue analysis (later in the video) shows that laser cut holes are better than punched holes, but it really is of academic interest as fatigue will occur after a million hours or something in either case (for those parts he was talking about). They aren’t finished analyzing everything before at least 1 1/2 month.

Funny thing is though, laser cut holes are done faster, they are cheaper and better than punched holes. But, obviously prone to human error when programming the laser, which IMO should be dead easy to fix with a minimum level of QA. I didn’t pick up on how many holes were cut correct vs wrong in the video.

The elephant in the room is still very much alive though. It’s called QA/QC. Van’s should IMO at least have some minimum control that the parts they ship are up to their own standard of how the parts should be, but they there appears to be none from what I could see. Is that deliberate, or is it a result of no one at Van’s has ever been involved with it? I would guess the latter. They are good engineers, but lack experience and competence in production (not unsimilar to Tesla  ) The result of this is that even though the builders complains about the quality of parts, Van’s simply say: “build on”. This will continue, and everything will be back to normal in no time

) The result of this is that even though the builders complains about the quality of parts, Van’s simply say: “build on”. This will continue, and everything will be back to normal in no time

@gallois, I didn’t say that the glue was wrong. The glue was indeed fine, from here

“La colle utilisée par la société Robin est la Penacolite G1131 fabriquée aux Etats-Unis par la société Koppers Company, Inc.”

the problem was that the glue was used in a wrong way:

“La société Robin, dans sa note n° NAV 76/3 du 26 février 1976, définit l’utilisation de la colle Penacolite G1131, laissant le choix de la méthode d’encollage sur une ou deux faces. D’autre part, le grammage prescrit (280g/m2) est nettement inférieur à celui qui a été appliqué aux essais en vue de la certification de la colle. La pression d’assemblage à appliquer serait de 1,7 à 17,5 kg/cm2 pour la société Robin alors que la société distributrice de l’adhésif recommande une pression minimum de 7 à 17 kg/cm2.”

I’m going to stop here. My intention was to show the laser cut holes from a different angle, not to criticise Robin Aircraft

I was simply pointing out that these things are remembered, within a given market and will often never be forgiven if the customer feels aggrieved and that grievance in not addressed to the customer’s satisfaction, especially in a small market place.

In a large market place you can get away with treating the customer badly. Think Ryan Air.

But… if somebody wants an RV, but is worried, what will he buy instead? Not a TB20, not a Robin (which has similar but much harder to verify “glue” troubles)… An RV is easy to check and anyway you just buy an older model. There are many advantages in an older model, you know

Peter wrote:

But… if somebody wants an RV, but is worried, what will he buy instead?

A Sling

Isn’t it kind of funny that a single video published on YouTube can swing people’s opinion 180 degrees?

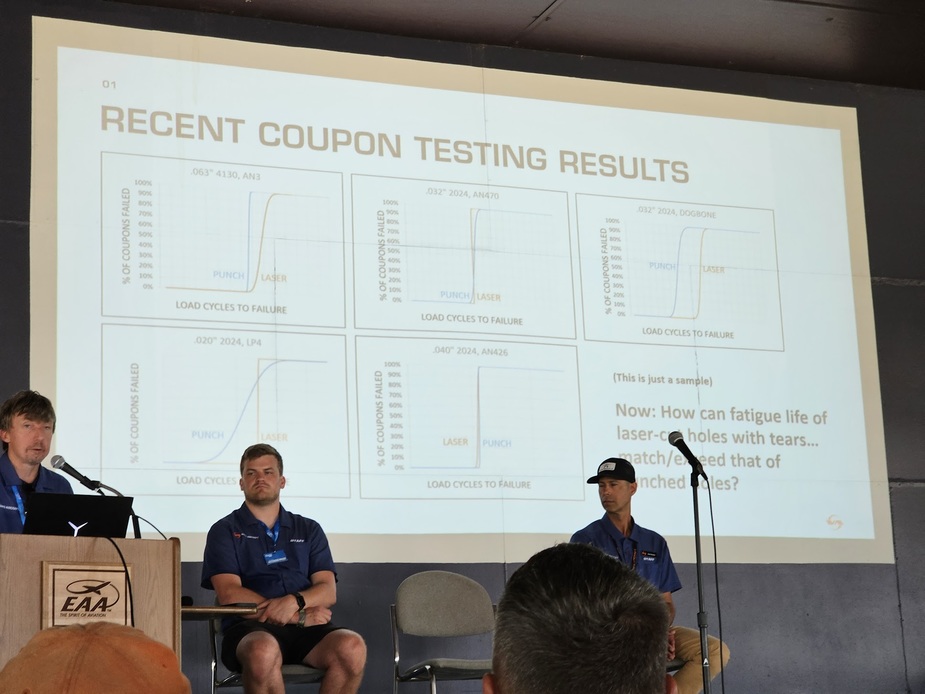

If their testing is half as sloppy as their graphs I wouldn’t have a lot of confidence. Any time I see a graph missing the scale on an axis I just assume it’s trying to be deceptive. Plus, zero data points so we don’t know how many coupons were tested and if there were any outliers. The lines on two of the graphs were vertical, suggesting there was only 1 sample. No legends on any of the graphs, on some it is nearly impossible to even tell what you are looking at.

All they need to do to convince me that they believe what they are saying is continue to laser cut parts. Is that too much to ask? It would be a lot cheaper than switching back to punched. That speaks volumes alone

As @LeSving pointed out, they are self governing so all they need to do is convince the lowest common denominator, in a herd mentality group, that has VAF playing cover for them. Apparently easy to do if you show a couple of slides of them testing parts that definitely are not laser cut. I say that because they said they have only tested coupons and no complete components.

Peter wrote:

But… if somebody wants an RV, but is worried, what will he buy instead?

Those “laser cut” unfinished projects might be a good opportunity to acquire decent airframes at bargain prices.

In RV10 and 14 almost every rivet joint can be inspected. Things difficult to inspect like ailerons can easily be rebuilt from scratch in a few days time.