LeSving wrote!

This thread is an example of vendor bashing, and rather openly so by some “bashers”. I mean public court, being expelled from Van’s because of it and so on. In some ways this thread has turned into some sort of, I don’t know, “public certification of Van’s” (which has failed by the “public court” ), based on poor data, inadequate knowledge, poor workmanship and purely subjective measures of “quality”.

Well, Van’s needs to update sections 5.2 and 5.5 because when they say, “The problem with small cracks is that they soon become large cracks, one piece of aluminum becomes two pieces, etc. Obviously, we do not want this happening in our airframe, particularly when separated from solid earth by a lot of very thin air.” Now that they are saying cracks are ok I would like them to put that in writing.

This was an obvious blunder on Van’s part. They will not even dispute that. I know they could still remedy the situation however, it would be very expensive. I don’t see how people’s opinion that this could have been avoided and upset over their lack of communication is “bashing”.

The flip side of the coin is the herd mentality that Van’s always makes things right. You hear that over and over again but with no recent examples.

Graham wrote:

Those advertisers will stop buying space if that space is full of criticism of their products, and it would be impossible to moderate the boundary between fair comment and vendor bashing so it’s just easier to make a rule

That’s Peter’s take on it. Sounds fairly plausible, but is it correct, and is that all there is? In my reasoning above, I think there are more to it, as it completely destroys constructive discussions. Van’s and other vendors use VAF from time to time in open discussions for instance, Q and A and so on. This is indeed very valuable, and will disappear without any rules about vendor bashing.

Besides, it is indeed fully possible to discuss every topic. The problem is only when (bad) feelings for a certain company takes the upper hand.

Graham wrote:

Van’s made a major mistake, mainly with QC.

That is also debatable. To be honest, I would say that laser cutting without removing the (possibly) heat affected zone, will always induce a level of uncertainty that we simply are better off without. Too many variables to control by too many people and too small tolerances. It becomes almost speculative. A principle is to reduce uncertainty where possible, not introduce uncertainty. Punched holes up to the correct dimension is more than enough uncertainty, but at least that uncertainty is rather constant for all holes, much less prone to variation. The least amount of uncertainty is made by drilling each hole up to the correct dimension, but this requires more work by the builder with no benefits for the kit manufacturer – unless using laser cutting, which many do  Punched holes have shown to be OK anyway, and this is what Van’s will continue to do from no on.

Punched holes have shown to be OK anyway, and this is what Van’s will continue to do from no on.

They could certainly include some checking at some points in the manufacturing and distribution process, but I simply don’t think they have it in them to do that. When that Trumpf 5000 (or whatever it was) is up to speed, it’s back to business as usual

Graham wrote:

I am trying not to rise to the insulting and largely baseless comments being made about builder knowledge and competence

That’s your choice. It’s odd you call it insulting. From those pictures in this thread, it certainly is not baseless, and when those pictures are used as “proof” of Van’s errors, it’s really hard to make a conclusion why someone would post such pictures. Homebuilt aircraft is about 3 things: Learn, built and fly. Everyone starts out as novices in the learn and built department, unless they have prior experience of course, which helps somewhat. It’s just that is always room for improvements, and this often causes new mistakes to be made  Learning is very much about making mistakes, and when letting others do large part of the process, you simply have to accept they will do mistakes as well.

Learning is very much about making mistakes, and when letting others do large part of the process, you simply have to accept they will do mistakes as well.

That’s Peter’s take on it.

FWIW, both myself and David (who wrote up the policy here, in 2012) have lots of experience of forums, going back to early 1990s. David even more than me, with running some huge sites I won’t mention.

There are certainly people in GA who would prefer to be able to post more or less anything, and they have told me so, usually on their way out of the door and heading for a certain other forum, which they came from originally en-masse, located somewhat nearer to central Europe

as it completely destroys constructive discussions

Those are allowed unless a certain (unpublished) line is crossed, and then advert revenue is at risk. Remember the US has loads of GA sites. Europe is tiny in comparison.

There are other reasons we don’t carry normal advertising. These are off topic but for example you will end up carrying adverts from crap companies (no shortage of those, and the worst ones do the most advertising) and then what do you do?? We’ve had a number of “legal threats” in that area, over the years. One example. The ethics of doing that are highly dubious. But you have to remember that most forums are run for revenue (if not direct then for promoting an associated magazine) and not because the owner is seeking to promote the said activity which is why EuroGA was set up.

LeSving wrote:

That is also debatable. To be honest, I would say that laser cutting without removing the (possibly) heat affected zone, will always induce a level of uncertainty that we simply are better off without.

Debatable by whom? Not Van’s. They are saying it was a QC issue. Largely due to a vender changing the cut pattern to one that I understand even a beginner CNC operator knows not to do.

The sad and troubling thing is Van’s just got done dealing with the lack of oversight with the quick build primer issue. They should have been extra sensitive to third party oversight.

LeSving wrote:

They could certainly include some checking at some points in the manufacturing and distribution process, but I simply don’t think they have it in them to do that. When that Trumpf 5000 (or whatever it was) is up to speed, it’s back to business as usual

The point about QC is that you check at some statistically significant rate that is also workable, i.e. you inspect X pieces from each batch and you have processes in place to make sure your sample is representative, e.g. you don’t always take the top one off the pile because the vendor always puts their best work on top. No-one is suggesting every piece ought to be inspected, but as of now it appears they have no QC processes at all. There is simply no way these pieces could have escaped it for so long if they did.

I also like the Trumpmaster Part Puncher 400 or whatever it’s called.

LeSving wrote:

From those pictures in this thread, it certainly is not baseless, and when those pictures are used as “proof” of Van’s errors, it’s really hard to make a conclusion why someone would post such pictures

Red herring. Those are not pictures of my work, they are ones I took from VAF. If you don’t like the guys dimpling (looks very crisp to me, the die was hit hard, but it’s all the right shape – I think you’re not seeing what you think you’re seeing) and his lack of primer then that’s kind of irrelevant. The point was to show the cracks. If you think his work caused the cracks, you can search and find a thousand other pictures of the cracks and I’m sure that eventually you can find some where the rest of the workmanship shown is up to your standard.

RV8Bob wrote:

Debatable by whom? Not Van’s. They are saying it was a QC issue. Largely due to a vender changing the cut pattern to one that I understand even a beginner CNC operator knows not to do.

@RV8Bob I think what @LeSving is saying is that the root failure may not be a QC one, but the decision to make the parts this way in the first place.

@graham wrote:

@RV8Bob I think what @LeSving is saying is that the root failure may not be a QC one, but the decision to make the parts this way in the first place.

Ok, maybe but that’s not what Van’s is saying. They are still saying good laser cut parts are better than punched parts. I could be convinced if they continued producing laser cut parts.

@LeSving wrote:

In some ways this thread has turned into some sort of, I don’t know, “public certification of Van’s” (which has failed by the “public court” ), based on poor data, inadequate knowledge, poor workmanship and purely subjective measures of “quality.

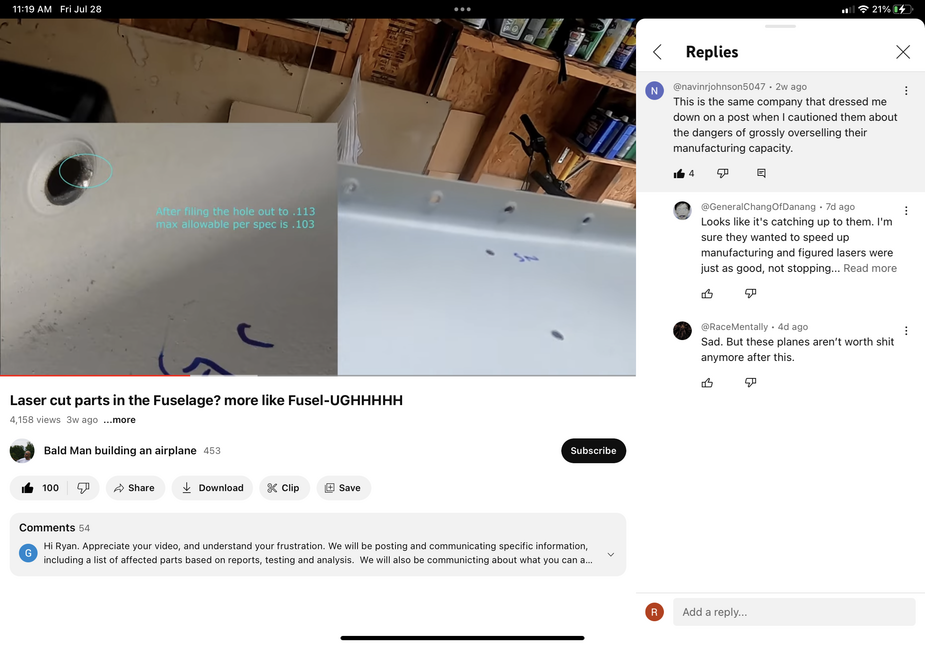

If you believe this problem is due to builders “poor workmanship” I challenge you to comment on this builders YouTube channel to that affect. Also note the reply about warning Van’s to not take on more than they can chew. We were all thinking it.

poor workmanship is in large part due to peoples belief that they don’t need to read and learn, no need for an experienced mentor. AC43-13? many never heard of it, FAA manuals? why bother when you can watch a few YouTube videos and you are not only good to go but can also “challenge” others

@RV14 and @LeSving, mentioning poor workmanship on this thread to the extent you are implies that you believe this problem, and essentially all problems, originate from the builder. It’s my belief this cult culture to protect Van’s reputation originated at VAF where builders receive that false sense of consensus.

If Peter says that anybody can post anything, than that let it be

I’m out of here

It’s sad that when people don’t have a strong argument they wish the other side gets censored or go to a place where that occurs. If the belief this problem isn’t caused by poor builder workmanship is so controversial that your sensitive ears can’t hear it and gets me censored. So be it.