What do you make of this brand new Service Bulletin from Piper? My impression is that it applies to all PA28, PA32, PA34, and PA44 aircraft ever made, including newly made ones.

i6OQoh_SB_1366_pdf

@Airborne_Again thank you my Warrior is still in bits, hopefully they can add this to the work sheet!

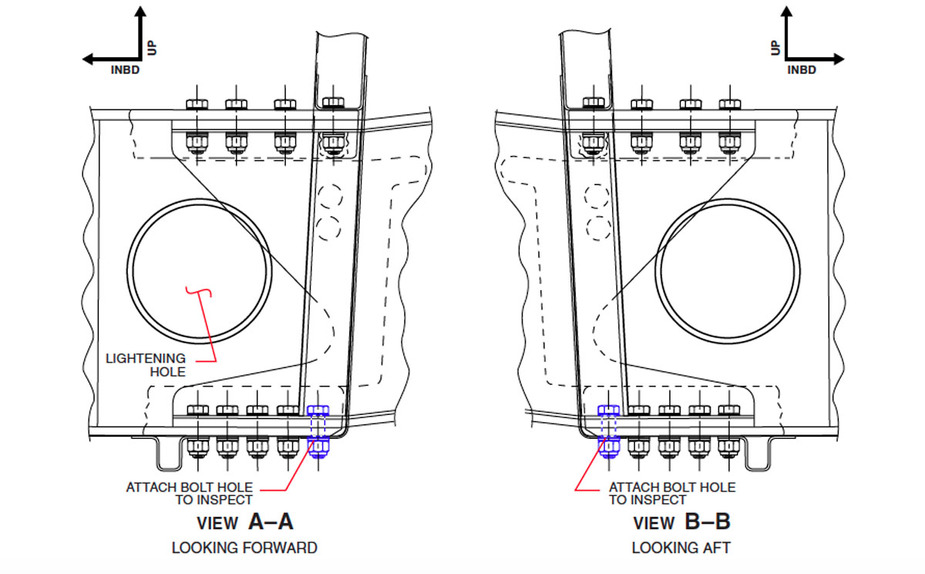

it relates to the AD for eddy current inspection spar attachment bolt hole. The AD requires fresh hardware to replace the bolt that has been removed.

Apparently Piper shipped several thousands of wrong washers recently with these hardware kits and are now issuing the SB.

The wrong washer was a square edged version (without the radius) which has the risk to cause dents on the spar surface when the bolt is torqued.

If anyone has done the eddy current AD recently needs to check the hardware replaced at the time of the inspection. It really sucks because it might mean that many people have to remove the bolts again to check the washer and replace.

Doesn’t it also relate to almost all planes to verify the correct bolts are in place? Or is this unlikely to be a concern on planes that had no spar EC inspection?

By9468840 wrote:

it relates to the AD for eddy current inspection spar attachment bolt hole. The AD requires fresh hardware to replace the bolt that has been removed.

Apparently Piper shipped several thousands of wrong washers recently with these hardware kits and are now issuing the SB.

It can’t be the only reason as this SB applies also to aircraft which were not affected by the eddy current AD. (Including the PA34 and PA44.)

How many wing bolts hold on the wing of Piper PA28/32?

I just took one apart today so I know all about it

By9468840 wrote:

Apparently Piper shipped several thousands of wrong washers recently with these hardware kits and are now issuing the SB.

If that is true, it will be an interesting liability case …

No different to Lycoming crankshafts and the other 1000 instances… they get creative in offering a compensation package and after that you are on your own, especially if the maintenance company forgets to implement it while the compensation package is active.

WilliamF wrote:

How many wing bolts hold on the wing of Piper PA28/32?

Can anyone explain why so many bolts are needed? Is there a mechanism where four of the five bottom bolts contribute anything at all, either to structural strength or long term durability?

If the first bolt (where I believe the failure have occurred) lets go, why is it neccessary to have four more? If one’s been left loose, chances are so have the others. So why not have 6, or 10, bolts?. And if it’s tight, how can any stresses reach the others? Perhaps I should be thinking spaghetti rather than aluminium!

Aveling wrote:

Can anyone explain why so many bolts are needed? Is there a mechanism where four of the five bottom bolts contribute anything at all, either to structural strength or long term durability?If the first bolt (where I believe the failure have occurred) lets go, why is it neccessary to have four more? If one’s been left loose, chances are so have the others. So why not have 6, or 10, bolts?. And if it’s tight, how can any stresses reach the others? Perhaps I should be thinking spaghetti rather than aluminium!

I think it is all about the manufacturing defects of a single bolt.

But why four/five instead of two? Who knows what they thought 70 years ago when they designed this? :)