Does anyone know if a TB20 can be off-jacks when the two gas shocks have been removed?

I think probably not, in which case people working on them regularly will have some dummy spacers made up.

The entire seal kit is actually very cheap, by any standards especially Socata ones. But according to my A&P the leak is from the valve, which would be amazing news because these are totally generic.

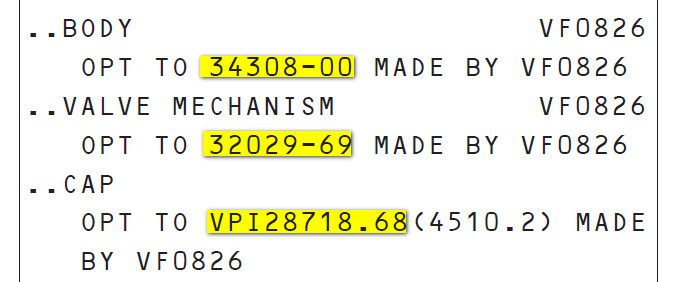

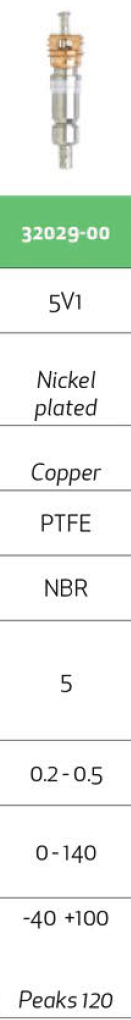

No idea what the -69 is. Here is the one without the -69

The mechanism probably doesn’t matter so long as the body is correct.

The main reasons to service the strut on jacks are:

-The working pressures are low and hence low press tire servicing equipment is enough and risks are low. When off jacks you need high press equipment. On large aircraft there are procedures to press it up without jacks but you need 1000psi or more (vs around 100) . Years ago one of our young mechanics almost lost hearing on one side when he hooked up an incorrect low pressure hose (for small tyres) to a high-pressure system for strut inflation, bursting the hose.

-It is easy to extend and retract the strut to ensure correct filling with hydraulic fluid

If the leak is on the valve, replacing the core will fix it. Make sure all pressure has been released before trying to remove the core.

If the leak is on the seals then of course the best thing is to replace the seals, but the process to dissasemble the strut and reassembling it without damaging the new seals may be non-trivial. An alternate process that works for a lot of people is to use Granville’s Strut Seal mixed with your hydraulic fluid. It works by re-softening hardened seals facilitating their correct sealing. It works as long as they are not very damaged.

IN order to extend the life of your strut seals, make sure the chromed exposed area of the strut is kept cleaned and oiled with fresh hydraulic fluid, whatever your aircraft uses, typically MIL-PRF-5606

Edited to correct on vs off-jacks…

Peter wrote:

Does anyone know if a TB20 can be off-jacks when the two gas shocks have been removed?

The unofficial emergency procedure for aircraft recovery goes something like this as long as the struts can hold pressure for some time:

1-UNload/lighten the aircraft as much as possible.

2- Raise all three struts to full extension by using high-pressure air (to avoid depleting your N2 if in short supply)

3- Insert wooden pallets of sufficient strength at a suitable location under the wing spar and fwd/rear fuselage frame as required, with sufficient and correct padding to support the aircraft’s weight at that height without damaging the skin or the structure

4- Slowly release strut pressure to allow aircraft to rest on wooden supports

5- Completely release strut pressure.

6- Remove strut valve core/s

7- Compress strut sufficiently to remove wheel/s.

8- Repair + service(only the liquid part) strut as required (if dissasembling strut you need to ensure gnd clearance is enough after removing wheel, hence make sure wing supports are as high as possible)

9- Reinstall wheel/s.

10-Compress strut + reinstall valve core/s

11- Use N2 to pressurize struts until aircraft is raised off of supports

12- Remove supports from under the aircraft

13- Deflate struts to correct height

NO liability accepted re this advise…use at own peril

Your aircraft’s manual may have guidance re this type of procedure

Brilliant info – thank you Antonio

Re the off jacks with removed struts, not that I will advise it, but I have seen low-wing aircraft raised on people’s backs while on all fours under the wing…

You may also forego the wing supports and just use fuselage supports if readily available, but if you only need one side then a wing support is better.

For the record, I’ve located the valve parts. They are very cheap from Socata and they are even more amazingly cheap from industrial sources (they are all generic industrial valves). The company recommended the 41071 core which has a higher pressure spec than the Socata recommended part. The static pressure in the gas strut is probably around 140 bar just sitting on the ground…

From industrialvalvesolutions.co.uk

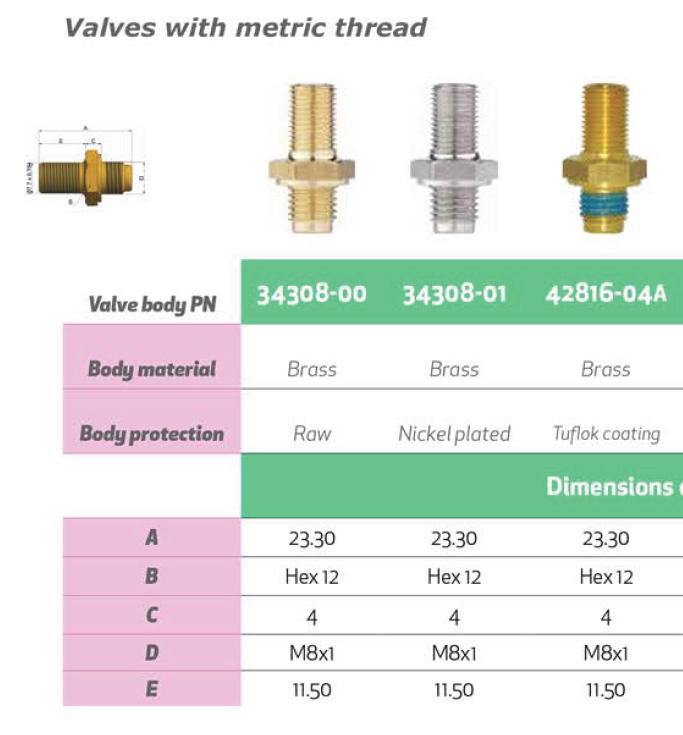

34308-00 brass finished M8 valve is £1.75 each, OR

34308-01 brass nickel plated finished M8 valve is £1.80 each

41071 – 700 bar high pressure core £7.20 each

28798-01 – high pressure cap – £2.50 each

66690-67 installation tool with torque limiter – £10 each

Their catalogue is currently here I have not done a local copy because it is 15MB.

Nothing special; you just can’t see them until you have dismantled the units, which you can’t do until it is on jacks, which you can’t do until you have got permission to do it in the hangar, and you can’t do anything until the entire seal kit has arrived

Rest assured that when the seal kit arrives, I will document the OEM equivalents (probably MS etc numbers) so everybody after me has an easy life

It could take a week or two even to get standard seals. It took me a week to sort out the valves and cores… but I am getting those from Socata also so I will be able to 100% verify they are identical.