I finally solved the problem of getting the gas out of these disposable bottles, without going through a chinese “valve pretending to be a regulator” thing which is just good enough for flushing aircon systems…

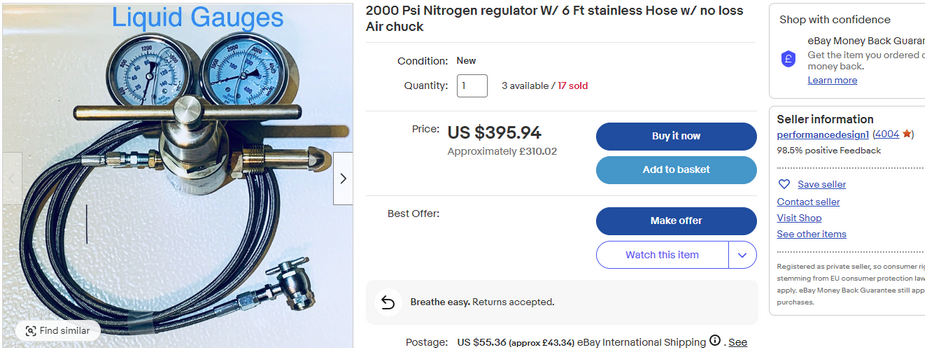

I bought this which is still a regulator but has a bit more “meat” in it.

Discarding the low pressure output gauge and the internals (there was a large diaphragm inside, with some springs), machining up the inside to take a brass bushing, reamed to 7mm, and turning up a 7mm rod with an o-ring seal

I get just the thing. The original regulator chamber is now vented (via two routes) to the outside so any leakage past the o-ring can escape. That chamber would never withstand 1500psi, which makes me thing the original device was never safe had the regulation failed.

The back port (not visible above) is now one of the two vents, the front port is blocked off with epoxy, and the outlet is on the right.

And by capping the outlet I can measure the pressure in any bottle without losing gas.

Tested it today, and it works. But there is a little problem. You do need to jack the wing up, although three sturdy firemen under the wing do the job well enough.

Answers on a postcard

Peter wrote:

Answers on a postcard

Is it because with the aircraft sat on the gear, the relative positioning of the components is such that you can’t get your kit into place to get it connected?

There is about a 3:1 leverage on the gas shock due to the trailing link.

So if there is say 300kg sitting on that leg, I would need enough pressure to lift 900kg.

With a 35mm diameter rod, I make that about 1400psi. This is hard because

I have a funny problem with that gas shock, still. It still has a leak; a slow one. I might gas it up once more and then will try that magic fluid suggested by Antonio.

To add another chapter to this saga…

I went to fill them both up again, this time with some magic fluid added.

One of them – the usual one – ended up about 3cm lower than the other! How is this possible? It’s not fuel in the wings (both full). And I personally filled them both with the same amount of Fluid 41. More checks showed that you put in say 700psi, disconnect the hose, reconnect it, and there is just 400psi in there. The disconnection is at the valve, using the usual method, so I think the only explanation is a “lazy” valve core which lets some air back out before it shuts off. It could also explain a leak…

Some of this stuff is from Socata and they often sell 20+ year old stock. Especially on parts which almost nobody buys from Socata…

Hello,

One interesting thing I would like to know about these struts is what is the remaining length of the chromed sliding rod to get the fluid just out from the valve, corresponding to the fluid quantity to be filled as per MM.

Tom

You have to depressurise the strut, remove it from the aircraft, and turn it upside down, then exercise it, and eventually the fluid comes out.

When you compress the strut (with your hands), the liquid shoots out very fast, as I found out to my cost, having to buy my son a new coat  Fluid 41 is nasty stuff so exercise usual precautions.

Fluid 41 is nasty stuff so exercise usual precautions.

The alternative is to dismantle it, for overhaul, as described in the posts above.

I also recommend filtering the fluid, with the sort of strainer used for spray paint

If you get dirt inside, it will bugger up the seals.

Yes Peter I agree with you about the filling procedure.

But I wonder if one can check the fluid quantity by measuring the strut compression at which the fluid would come out from the valve (after having removed the valve core) and without removing the struts form the plane.

Last time I had to service the struts I forgot the check this thing.

As a final chapter on whether one can gas-up the struts with weight on them, you can with something like this

That has a special regulator which can reach a high enough output pressure; most don’t go above 800psi or so. 2000psi would do a TB20, empty, full tanks, no problem.

Not sure if the CGI-580 inlet connector fits European nitrogen cylinders though. UK cylinders tend to use the “BOC bullnose” which may be the same thing but nobody in the business wants to discuss this; they just want to sell/rent you a cylinder  On the regulator input there is a funny thread which I have never managed to identify despite extensive enquiries.

On the regulator input there is a funny thread which I have never managed to identify despite extensive enquiries.