Silvaire wrote:

Prior to that buying new cylinders was price prohibitive, but at a certain point it became easier to buy new than overhaul and many of the cylinder specially shops went out of business.

Well, it may well be that this is a business idea which could be of some merit to bring this method back.

Ultranomad wrote:

A new cylinder assembly in itself is more expensive than overhauling, but using it saves turnaround time and labour costs significantly, so at the bottom line it’s comparable.

Last time I asked one cylinder for a O360 was around 1000 $ or so, so a whole set is about 4000. labour cost is horrendous here. Yet, I think if there are simply no new parts (and it is not limited to cylinders) to be had, overhauling what we have is going to have to be the way forth.

Mooney_Driver wrote:

It doesn’t look like a sporadic thing, particularly engine parts and props.

It’s definitely not sporadic, and not limited to engines and props. Where manufacturers had sufficient stock or more localized supply chain it’s less of an issue, but there are many areas where this is a big problem. Global personnel shortages are equally problematic. After 3 months we still have no delivery time on GI-275 components we need for our installation. I just ordered a very simple Lycoming filter adapter that was out of stock at every supplier except one in the US which had 2 left. A simple perusal of your favorite aircraft supply shop will show many items out of stock.

Silvaire wrote:

The problem is Europe is relatively lack of flexible, capable GA infrastructure that can adapt to circumstances. Same as always.

The problem has nothing to do with Europe or even GA. It’s a global supply chain/personnel issue affecting many industries. I just took delivery of a car I ordered in April, and VW told us back in March that it was starting to sell cars with analog gauge instruments due to display shortages. Container ships in many ports are piled up waiting to unload for weeks or months. Considering this has been pretty much constantly in the global news for the last year plus, it seems strange to blame local industry politics.

I thought my point was pretty clear: if you have local cylinder shops with CAA or FAA etc approved procedures to overhaul aircraft engine cylinders, you are not as dependent on an international supply chain for new cylinders. If you do not have such a shop close-by, or in other words do not have a flexible, capable GA infrastructure, you are relatively speaking screwed. That infrastructure for GA aircraft engines does not exist in Europe.

Another example is crankshafts. If for example Peter’s favorite US engine overhaul business (Barrett Precision, one of many such businesses) red tags a customers Lycoming or Continental crankshaft during overhaul, they can often call around and find a used but reworkable replacement from e.g. Junior Jurnigen in Florida, who searches his substantial inventory of used parts to find one. It doesn’t matter if the part was otherwise destined for an airboat engine because Barrett can certify it after rework. The players all tend to know who has what, even if the end use engine overhaul customer does not.

There is a portion of this issue which in GA is harder in Europe simply because there are fewer component repair facilities here.

In the FAA system, an A&P has the authority to inspect a part and declare it airworthy (or not), and there is an A&P on every corner (and for those who want or need paperwork there is a 145 Repair Station on every corner) whereas in the European system you need “paperwork with everything” and there is a significant bar (high threshold) to getting the authority to generate this paperwork. As a completely natural consequence, those who are able to generate the paperwork then lobby for the maintenance of this regime  You need to only read EuroGA posts from 5-10 years ago to find certain “industry” people defending vigorously these dubious practices, claiming that they safeguard from counterfeit items, etc. Here is a good one. Here is another. A lot of good work by EASA to reduce this burden has been sabotaged by the industry e.g. Part-ML concessions like this are widely disliked at industry level (due to the revenue reduction) and if you push your maint. co. to implement them, they might just kick you out.

You need to only read EuroGA posts from 5-10 years ago to find certain “industry” people defending vigorously these dubious practices, claiming that they safeguard from counterfeit items, etc. Here is a good one. Here is another. A lot of good work by EASA to reduce this burden has been sabotaged by the industry e.g. Part-ML concessions like this are widely disliked at industry level (due to the revenue reduction) and if you push your maint. co. to implement them, they might just kick you out.

As a little example, a few years ago I found a supplier (the US based Mouser.com) selling discontinued Mitsubishi relays, used by Socata for the flap operating mechanism. They were on a very long lead time because of the EU ban on cadmium (on the relay contacts) forced the withdrawal (scrappage) of stocks. I bought something like 20 of these (with cadmium contacts) and after a year or two they actually arrived. I then offered them to Socata TB owners for some pretty nominal (by aviation standards) price, but IIRC nobody was able to use them without paperwork. One guy managed to sneak them in without his maint co. noticing  The bottom line is that you could be grounded for months over something stupid like this. In the US, they use cadmium freely – it is a good solution to the requirement.

The bottom line is that you could be grounded for months over something stupid like this. In the US, they use cadmium freely – it is a good solution to the requirement.

This is a classic – people needing paperwork for M4x10 stainless steel screws. I did eventually sell my entire stock of them – over 1000 I think. Nearly all to Americans.

So basically the effect of any shortages is worse in the system over here.

As to why we have the shortages, I think when somebody is quoting 2 years for a new cylinder, somebody must be taking the p1ss. Has anyone directly emailed any of the big US engine rebuilders? If this problem was widespread they would all go bust due to the lack of parts.

This article lays options for aircraft engine and/or cylinder overhaul, parts required for each etc pretty clearly, and also provides some info on making the decision to overhaul, or not.

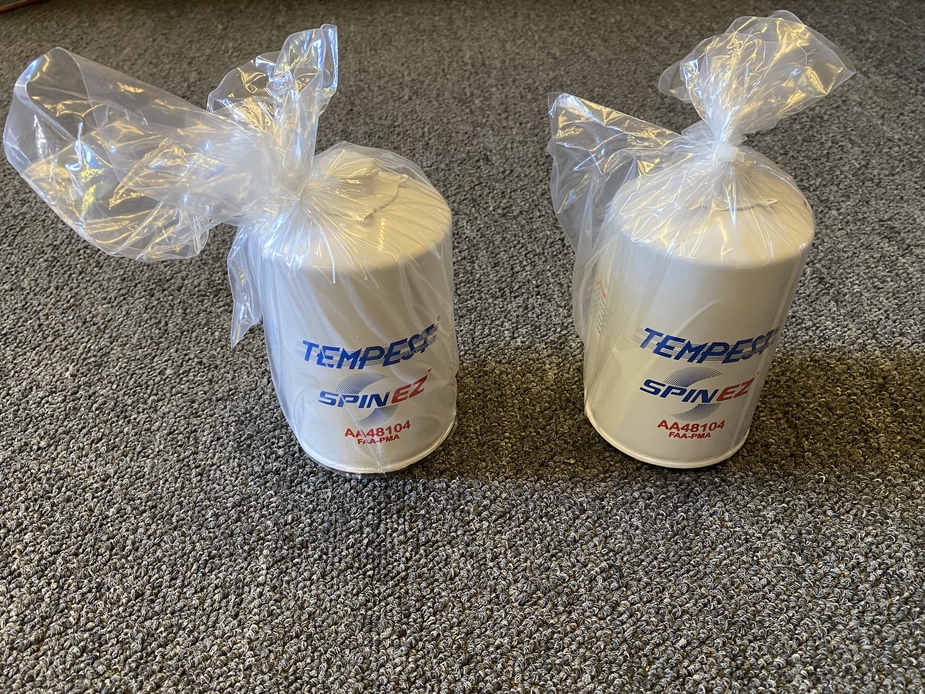

I received a couple of 48104 filters this week from Chief Aircraft and they’ll keep me going for quite a while.

Silvaire.

When I started in this business forty-five years back we overhauled cylinders as a matter of course and some companies performed weld repairs on cylinders, the only problem was the increasing unreliability of these cylinders.

The reasons for the unreliability of overhauled cylinders was two fold age ( and the number of times the cylinder had been around the block ) of the way the last owner had treated the cylinder.

So the previous history of a cylinder is the deciding factor as to if I would fit an overhauled cylinder, if it was one of my old cylinders or had come from a very well controlled operation I would be happy to fit it. If I did not know the cylinder’s history then for £1000 it is not worth the gamble on the cylinder prematurely failing. Under any circumstance I would not fit a cylinder that had been welded in the valve seat or spark plug area.

For the last few decades the difference between new and overhauled cylinders has been small so it hasn’t been worth it.

With the fall in the pound I was quoted 1800 quid for an O-200 cylinder earlier this week.

So I have been in discussion with our engine man about overhauling our current cylinders.

These cylinders have a known history will have 2400 hours on them and all have been ‘topped’ once.

They wont be overhauled a second time.

Yes, the context of the discussion is that new cylinders are apparently unavailable (or cost prohibitive)

Bathman wrote:

With the fall in the pound I was quoted 1800 quid for an O-200 cylinder earlier this week.

With what delivery date?

Silvaire wrote:

the context of the discussion is that new cylinders are apparently unavailable (or cost prohibitive)

Exactly. Bog standard O360 Cylinders nowadays appear to have a delivery date sometime in 2024. If it’s only half as bad as currently portrayed in some places, overhauling cylinders wherever possible would sound perfectly reasonable, under the provisions stated by @A_and_C and others.