boscomantico wrote:

Back to the general topic, does anyone have any insight on what is really going on? These Rotax engines have been installed, often very crudely, into 100 different types of microlights in the past 30 years, and they always ran more or less ok, if the carbs were ok.What happened? Is it really just the numbers of certified and non-certified aircraft with these engines have slowly grown more and more, thus uncovering a problem that has always existed to some degree?

Looks like Aquila has already issued a SB to modify the exhaust system (link).

Most of the events listed on the BAZL site mention the AT01. So time will tell if this SB brings improvements.

What I can say to the B23, this is a rather new plane. I had a training for about 5-6 hours on a B23-912 in a flight school, that months later had an engine failure on take-off. On my pre-flight checks when opening the cowling cover I noticed blackened parts on the cowling beneath the engine, clearly a sign of overheating.

Bristell has already issued a SB last year to install a bigger oil cooler, perhaps this improves the situation.

gallois wrote:

Many have been doing this for several years, and some have clocked up several thousand hours all without fuel issues or engine damage.

Do you think perhaps you are overthinking this?

I have been towing gliders for years myself. First in a Pawnee, then in a soup’ed up (Edge Performance) Rotax powered WT9 Dynamic. I have had my shares of happenings in both planes (regardless of fuel  or lack of such) The engine will handle 95 E10 just fine, the aircraft, possibly not depending on how the aircraft is designed. As I said, Atec issued a SB about the Faeta. It will not tolerate E10, the wings will delaminate. And there are others. Then there is storage problems. Phase separation in E10 is well known.

or lack of such) The engine will handle 95 E10 just fine, the aircraft, possibly not depending on how the aircraft is designed. As I said, Atec issued a SB about the Faeta. It will not tolerate E10, the wings will delaminate. And there are others. Then there is storage problems. Phase separation in E10 is well known.

Things have a tendency to be OK until they suddenly aren’t. There are enough problems around regarding aircraft. Most of them we never hear of, but we know they are there. E10 is a problem all by itself IMO. A problem we can easily prevent simply by not using it. There is no good reason to use 95 E10 when 98 E0 is readily available. It’s as simple as that. The same goes for 91UL. That Hjelmco looks very interesting all of a sudden. Like the best of both worlds.

Maybe Norway can do a deal with Brussels to pay over some more money and in return for that not have to implement E10

LeSving wrote:

Things have a tendency to be OK until they suddenly aren’t. There are enough problems around regarding aircraft. Most of them we never hear of, but we know they are there. E10 is a problem all by itself IMO. A problem we can easily prevent simply by not using it.

easier said than done I’m afraid

Where would you find 98 in NE of Sweden or Norway, say east of ESUG?

LeSving wrote:

Then, under which stone have you lived?

I guess you have more stones up in Norway

LeSving wrote:

I don’t think they have tested it at all. What they have tested is “a” fuel, and found if the specs are according to what’s in the Rotax manual, then it’s OK.

So are you saying, that the Total and BP Avgas UL91, which is sold at airports are not up to the specifications they claim? Hm….

Antonio wrote:

I don’t get it. How is it the opposite?

I mean, that, no matter what manifold pressure – using high RPM with a Rotax is always good according to Rotax.

https://www.kleinjung.de/rotax/doku.php?id=einstellung_der_leistung

This guy worked for Rotax for 20 years and has now retired. He is still very active in the german "Rotax-community "and his detailled recommendations with a practical approach are much appreciated. His homepage is german only, but could maybe get translated via DeepL or the like for those who are interested…

europaxs wrote:

https://www.kleinjung.de/rotax/doku.php?id=einstellung_der_leistungThis guy worked for Rotax for 20 years and has now retired. He is still very active in the german "Rotax-community "and his detailled recommendations with a practical approach are much appreciated. His homepage is german only, but could maybe get translated via DeepL or the like for those who are interested…

That’s very interesting. He gives two arguments for why a low engine speed is bad (translated):

@LeSving why will the wings delaminate with E10?

Embraer have been using alchohol as a fuel for several years now.

Last year and for a few years before that, there were a significant number of engine failures recorded on Cirrus aircraft and several deaths, despite the parachute. I have no idea why these engines failed but why was there not a thread on this forum titled “Significant problems with Cirrus engines?”

And why were there not posts on the disadvantages of using 100LL in such engines?

gallois wrote:

why will the wings delaminate with E10?

Because they are not designed particularly for it, incompatible resin or whatever. Here is from Atec.

gallois wrote:

I have no idea why these engines failed but why was there not a thread on this forum titled “Significant problems with Cirrus engines?”

And why were there not posts on the disadvantages of using 100LL in such engines?

Because they Swiss didn’t write about it?  Seriously, someone has to write or say something before others take notice.

Seriously, someone has to write or say something before others take notice.

europaxs wrote:

So are you saying, that the Total and BP Avgas UL91, which is sold at airports are not up to the specifications they claim? Hm….

That’s what ULPower said, and they have tested them, neck to neck with MOGAS 95 which was OK (fresh MOGAS 95). This was during a training course I had there. It was said, but the official statement is UL91 is OK, because it should be OK according to spec or quality certificates. According to the standard, RON should be minimum 95 for UL91. Hjelmco has according to their test sheet, a standard of minimum 98.

Looking at that Service Instruction from Rotax, it is blindingly obvious that Rotax knows for a fact that aircraft producers aren’t taking their job of integrating the engine into the airframe the way they should, to make sure the engine runs properly in all circumstances and with all fuels the aircraft manufacturer specify. If you read those advisory circulars (that every Rotax owner should read, according to them), it’s crystal clear what this is all about. That service letter is only a few days old.

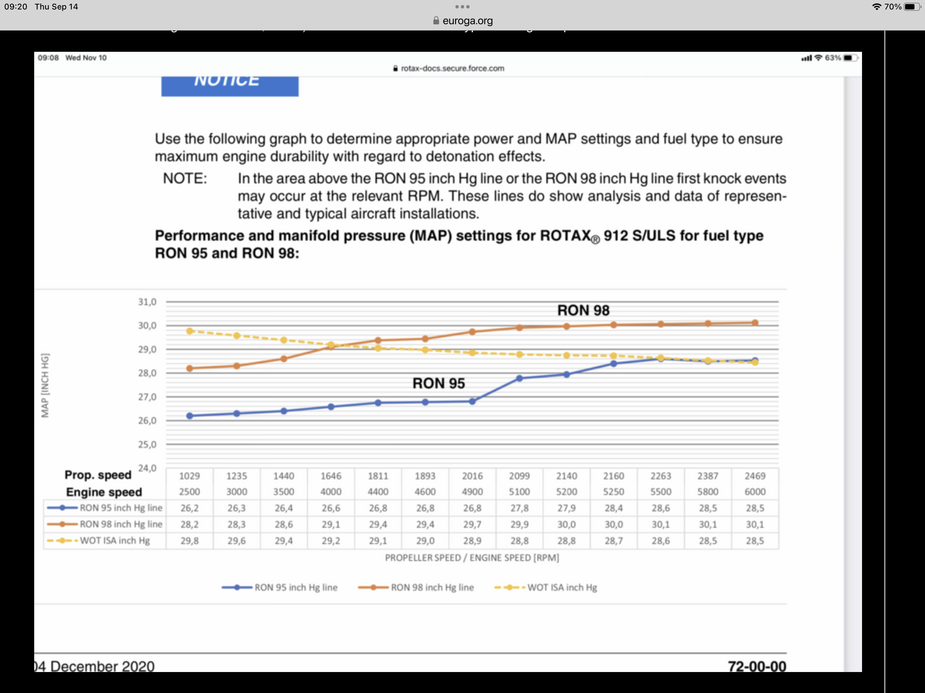

Here’s the graph that all Rotax 912 ULS/S flyers know. Or should know..

In addition, Rotax says to take into consideration the knocking characteristics of the different Mogas types:

I’ve always taken above limitations into account. I use Mogas 95 with 5-10% Ethanol.

BRM (Bristell) has recently updated the AFM of the B23-912 where they introduce a further limitation: “be careful with high RPM and low MP as it will increase EGT and oil temp and increase wear on the engine”.

I have observed these temp effects myself.

On oil temp it is perceptible, but I have never come near the limit of 130 C and maybe just a few times in the caution range of above 115 C, even with the high OATs here and only in climb, never in cruise where I see 90-95 C in summer generally. Btw, Rotax says to make sure to reach a minimum of 100 C for each flight day.

When it comes to EGT there is also a rise when at relatively high RPM at a modest MP. Rough numbers: 820 C at 23/5200, decreasing to 800 C at 23/4800 and to 750 C at 26/4800. Red line is 850 C. However, one does get near red line on final approach where MP gets reduced further and RPM is increased for the possible go-around. So I’ve always delayed to do ‘prop forward’ until very short final and immediately further reduce MP so I never have this problem, insofar as it is a problem because I always thought that EGT is not such a big deal. BRM has added to the AFM the procedure I have been doing on final approach btw. What’s also noticeable is the lower EGT at altitude. When pushing the gas lever forward to maintain MP the mixture gets richer, resulting in a lower EGT.

I’ve always been taught that oil temp and CHT are more important than EGT. My oil temps have always been fine and my CHT’s are always very stable and very much lower than the limits (80-90 C vs the limit of 120 C). And I live in a hot climate. I actually have to do my best to get to the 100 C oil temp every flight day as recommended. In winter need to partially blank the radiator as most Rotax flyers do.

So maybe in the end these knocking characteristics of 95 Mogas is an issue? Then again, @boscomantico said the Bristells in Germany used 100LL and UL91.. And most use 95 Mogas across Europe.

All a bit puzzling. Looking forward what comes out of the findings of the various authorities/Rotax investigation.