From here

Interesting post, especially as I’ve been renting a Rotax powered plane with a CS prop recently.

I do like the Rotax engines, extremely smooth and responsive and great efficiency too.

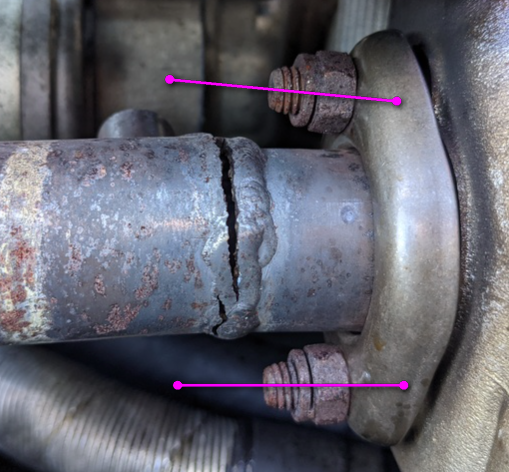

I did however get stranded last weekend, I had a full day of flying planned with 5 separate legs. On startup on the second leg, the engine sounded very “tappety” (think a 90s Japanese car with dodgy hydraulic lifters on a cold morning) which was definitely not right. Removed the cowl and was presented with this:

It looks to have been welded here previously, and the school I rent the plane from has assured me they will now replace the section instead of welding it again.

There was a rubber fuel hose 10cm away from the exhaust, luckily the exhaust must have failed during descent or it would have been squirting 1000F+ exhaust gases onto the unprotected rubber fuel hose. I have also requested that they put some fireproof sleeving on the fuel hoses.

In future I will remove the upper half of the cowl as part of my preflight inspection.

I like the angle of the two studs

How long before one of them pops out?

I had mine welded up recently – wonder whether that is a good idea generally.

The exhausts used on Rotax engines often seem to give problems. The exhausts on several Rotax engines here have had to be replaced. The mechanics advise changing a section not welding as shown above.

At least the angle of the nuts makes it easy to undo and remove the whole exhaust:)

Part of the preflight on our Rotax ULM is to always remove the cowling and have a good look. The glider club do the same with their Ikarus or at least before the first tow.

Good thing you caught it in time. History recounts more than one nasty accident following this kind of failure.

And yes, all fuel and oil lines firewall forward should be firesleeved.

Exhaust is a wear item and must be checked (and replaced) egularly.

@Peter, the angle of the studs is caused by over tightening of the nuts, followed by the flange bending, which then bends the studs. The studs are made from ductile material and are unlikely to fail as a result, but both they and the flanges need to be replaced.

Weld repairs when done properly are acceptable practice. I’m not sure a 360 degree butt weld on corroded and dirty pipes near the exhaust port would qualify.

the angle of the studs is caused by over tightening of the nuts

That is exactly what I thought

If the studs were really angled, the holes in the clamp would need to be oval otherwise you would never get them off…

My experience with Rotax exhausts (in uncertified aircraft) is that they are not as long lived as exhausts fitted to conti or Lyco in certified aircraft..

However brand new replacements are a lot cheaper so there is really is no need to weld up things like down pipes.

I really wonder why and how one would overtorque the studs, because the nuts intended to go there are made of copper and should not be able to do any harm to the installation. The ones on the photo do not look as if they were, though.

Maybe someone decided to install some “proper” steel nut and tighten those “properly”?

From my experience the exhausts fit nicely and do not need much torque (12 Nm!) to tightly seal at the cylinder head.

Overtightening is really common in aircraft maintenance. It is usually why cylinder studs come off sometimes. The reason is usually that you can’t get straight-in with a torque wrench and the mechanic doesn’t know how to calculate the setting when the adaptor is used.