Good evening,

I wonder if you have seen this problem before and can help please.

during a flight the ALT light illuminated and the AMPS went to zero, shortly followed by LOW VOLTS light on .

engineers said the alternator brushes were worn, renewed, fault reoccurred.

engineers said it must be the alternator, changed that for a plane power one, fault reoccurred.

engineers said it must be the alternator controller, changed that for a new lemar unit, fault reoccurred.

changed that for a second hand one thinking the new one was faulty, fault re-occurred.

sometimes it goes for half an hour before the fault reoccurs, sometimes its just minutes.

Racking my brain as to what it could be, faulty master switch? or faulty battery? new alternator faulty?

Your thoughts gratefully received.

peter footitt , brighton aviation.

Hello Peter

And I also recognise this “troubleshooting method”  First example was on a Datsun 100A F2, 1978. GA “implementations” of this method came to my attention many years later.

First example was on a Datsun 100A F2, 1978. GA “implementations” of this method came to my attention many years later.

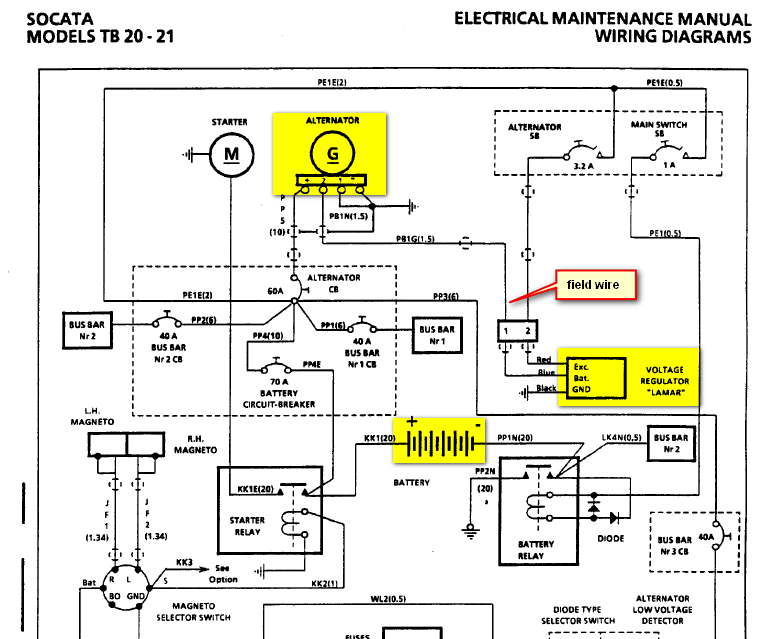

It will be hard to narrow down unless it can be reproduced on the ground – unless you get lucky with a visual inspection. But the basic principle is easy enough. You are talking 1970 Vauxhall Viva level of sophistication, so let’s use the TB20 circuit:

It has a lot of dross on it but basically the voltage reg has 3 wires: ground, bus sense (which also powers it), and the field wire. The reg draws current via the field connection which in turn controls the alternator output. No current = no output, max current (the voltage reg is a short circuit on the field wire to ground) = max output. The changeover happens around 28.0V. Below about 27.5V the reg draws max field current and above about 28.5V the reg draws no field current. Between 27.5V and 28.5V there is a linear relationship, and this is how the regulator controls the bus voltage around 28V (or 14V if yours is a 12V plane).

A complication is that the more recent LAMAR regulators are switch-mode and instead of drawing a steady current, they turn it on/off very fast (~200Hz) and the duty cycle varies between 0% at say 28.5V and 100% at say 27.5V.

So if you had to troubleshoot this properly, you want to connect an oscilloscope on the field wire, and a voltmeter on the main bus, and see what is happening. Running a wire from the field connection to the cockpit should be easy; you want to do this test safely and pleasantly, from inside the cockpit. The problem is that just sitting on the ground, engine running, it will probably work just fine – unless you get lucky and it doesn’t.

But given that both the reg and the alt have supposedly been changed, I would start with simpler things:

The crappy connectors used in GA would be the first thing to look at.

I hope whoever did the previous work has given you back the removed alt and reg, so you can have them as spares

When this happened to me in the -161, much pointless ‘fault finding’ ensued culminating in hand carrying an alternator to Helsinki for a return flight, but the fault kept coming back. Eventually one day when the baleful red light came on yet again, I flicked the alternator field CB with a fingernail and Bingo! Normal service resumed. No amount of pressing the CB did anything of course, but a sharp tap…

Moral: carry a hammer!!

Yes it could be a faulty field current CB.

Hi Peter,

Thank you for the information.

I will get the old alternator and controller back, there is a core charge on the old unit

There are a couple of tests in the maintenance manual that can be done on those parts using a variable power supply and an ammeter.

I shall test them both when they are back to work next week before i return the old alternator to Adams

They only seem to have a multimeter in their toolkit.

I would not return anything unless you have to to get a core charge back – because those items are probably OK.

I am happy to pop down there and have a look.

Yes it is easy to bench test a voltage regulator. One just needs a variable power supply (around the bus voltage) and a resistor to act as a dummy load to simulate the alternator field current.

How old is the firewall forward wiring ?

Both the alternator and the regulator don’t stand a chance of working correctly if the cables connecting them are corroded internally and damaged by prolonged and repeated heat exposure. Additionally and fault finding investigation and component replacement is likely to be unreliable as the electrical resistance within aged cables is likely to change due to environmental conditions or vibration.

A twenty year old cables forward of the firewall are simply unpredictable , therefore unreliable and with this in mind every inch of the fifty year old car quality wire on my Robin has been replaced after it tried to set fire to the aircraft, fortunately for those with American aircraft the higher quality cables on most aircraft will still be reliable in the areas that are not exposed to the outside environment but I would start to look at the cables that are in the more environmentally challenging areas.

Following problems much like those at the top of the thread I replaced all the firewall forward cables on a C152, this was so successful that at the next maintenance input my other C152 & PA28 got the same treatment resulting in an end to electrical generation problems.

I’ve had this probem before and with a very similar process where the maintance outift doesn’t do any testing just replaces stuff and sends you the bill. And then it still doesn’t work.

I would very much suggest you listen to what A_and_C has to say. I would of saved a fortune if I had.

And no I didn’t get what I suspect was my perfectly servicable alternator back either.

Intermittent issues can be very hard unless you get lucky, and 10x harder if the maint guy can’t follow a circuit diagram / doesn’t know how to use a voltmeter.

I know a guy who had a diesel Robin (yes; one of the “new” ones) and it would not start. The starter was replaced, the starter relay was replaced, the battery was replaced, maybe even the G500 was replaced (it monitors the engine so they thought it might be the cause) and in the end, after months of downtime, somebody fixed it (don’t know what it was) but they had so much other trouble with the plane that the dealer agreed to take it back for a refund. The manufacturer had been making simple planes for many decades and was incapable of supporting this plane. But actually the relevant circuit diagram was absolutely trivial.

Thank you peter for your offer of help, theres a few things i will test first and get back to you, i’m waiting for a 1/2W 1k ohm resistor in the post! so i can test the original regulator, i dont think it was tested properly before being replaced.

The alternator, although needing brushes, has done 1800 hours, so i think i will return it to Adams to get my core charge of £200 back, if it was newer i might keep it.

I will have a look at the 5amp circuit breaker, although it hasnt popped, Aveling has raised a good point, i will bypass it to see if it has any effect on the fault.

I have also bought a new master/alt. switch, i’ll get them to fit that as well if the breaker is not the problem.

And A & C, how much is it likely to cost to replace the forward wiring please?

Thank you for all input and wish you a happy new year.