Does anyone know of a firm in the southern UK which can pull cylinders, replace piston rings, etc, and which has the right tools and procedures?

And is at an airfield?

One firm I know doesn’t even know about the crankcase clamping!

Going to Mykonos for a party weekend would be possible as well.

Now that the Ramrod Bar is gone, it’s probably not my scene anymore  But, how much would EGKA-LGMK be in a TBM? (serious Q)

But, how much would EGKA-LGMK be in a TBM? (serious Q)

Peter wrote:

But, how much would EGKA-LGMK be in a TBM? (serious Q)

It’s about 1400 NM so not doable in one go with a TBM. You would do a stop where Jet A-1 is cheap. I would assume 5h flight time. Wet charter of a TBM 850 Elite is 1100 €/h + VAT over here but we have very expensive Jet fuel for non AOC and a 850 Elite is worth $2.8m whereas an old 700 would be under $1m.

So let’s say 10k€ for the weekend trip all in all, including 48h of ramrod activity and the coke that keeps you fit for the return flight.

Affirmative!

But before I would do anything I would fly another 20 hours … might as well go down again. I had that last year (reason unknown…)

Peter wrote:

Does anyone know of a firm in the southern UK which can pull cylinders, replace piston rings, etc, and which has the right tools and procedures?

What are you planning to do once you pull the cylinder(s) ?

Replace with new kits, overhaul cylinder or re-ring and hone cylinders ?

Clean up the rings and fit new ones. Probably 2 and 6 are the stuck ones.

I am sure the cylinders are fine. The engine was rebuilt to new limits all the way through at 800hrs (800hrs ago). Compressions are 78/80 or better so valves are OK.

Valves might be “OK” but not great for sure. When you got the pots removed and fit new rings (which requires honing and a break in), then it’s also a smart move to replace the valve guides and valves. Costs about 700 € all in all for one cylinder.

Don’t know about the UK but I know two good shops in Germany where you can fly in the morning and leave in the afternoon with everything done. With one company, you could assist (= annoy/harass) the mechanic during all work.

Could you share where in Germany you would recommend to do Cylinder work done.

With the crap Continental ships, Im more keen on OH my own cylinders, than to buy new.(known time in service)

So 700€ pays for:

New rings

Honing of cylinder walls

Replacement of valves and guides

??

If so, thats a much better option than a new Cylinder at 2000€, or about 1700€ for an unknown TIS OH cylinder.

Doing some proper due diligence on how, where and how much with regards to Cylinder work, will pay off quickly, when a Mug have to come off. And it will sooner or later on a TSIO-520 :(

Rieger in Vilshofen EDMV. The place looks like it’s taken from a 1960s movie but that is just about right for working on our airplanes  Straubing is more posh and high end but Vilshofen has the piston expertise and a very comprehensive cylinder workshop. They can do everything and they are very flexible and nice people.

Straubing is more posh and high end but Vilshofen has the piston expertise and a very comprehensive cylinder workshop. They can do everything and they are very flexible and nice people.

The other one I think is Röder in Egelsbach but I kind of prefer the South German relaxed atmosphere over the ISO9000 customer service representative approach

spirit49 wrote:

So 700€ pays for:

Yes, I paid 700 € for all the work you mentioned on a large bore Lycoming cylinder. The Conti parts probably cost about the same. I’m not sure re-honing and new rings and valve/guide is a good approach for fixing tired Conti cylinders. They have the bad habit of cracking and separating the head from the barrel so I would probably go for new replacement cylinders. Never ever think about buying overhauled cylinders, that is playing Russian roulette! No Part 145 I have dealt with would install OH cylinders.

In the 300hp range, a Conti cylinder lasts about 600-800h.

Valves might be “OK” but not great for sure.

With 78-79/80 compressions, the valves will be fine.

When you got the pots removed and fit new rings (which requires honing and a break in)

Why would new rings require a re-hone (assuming there is no glazing)?

I have just got the oil burn for the last flight and it is about 30% less than on the previous flight, per hour, but still burning too much.

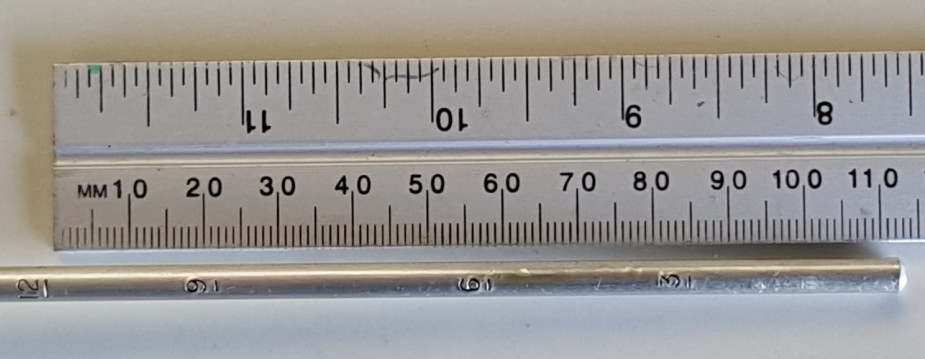

I took a photo of the dipstick which has nonlinear markings so will try to produce a scale of some sort, or maybe will just fill up to the same point before each flight (and make sure it is below “9” because anything above that gets wasted quickly)

Thank you for the info.

achimha wrote:

fixing tired Conti cylinders

Why would these Conti cylinders be so tired, if most of the time its only the valves that are the culprit?

Fix the valves, and hone/new rings, and they should be as new. Or?