Peter – Have you not borescoped the cylinders ? Good chance (not 100%) that you may see some tell-tale signs of piston ring problems – they usually show-up by leaving a visible line on the cylinder wall.

Also, your plugs look awefull ! Don’t you ever pick all those bits out ?

I’m betting on Cylinder #2 and maybe # 6 having ring problems.

I will do a high power flight, 1-2hrs, and re-examine plugs 2,4,6 and get fresh photos which I will post.

Yes I do dig out the crap  But to be honest if you put those bottom plugs back in the upper positions, they come out clean the next time you look

But to be honest if you put those bottom plugs back in the upper positions, they come out clean the next time you look

I swapped the top and bottom ones around and if 2 and 6 look the same, and there is still a lot of oil burn (more than 1qt in 4hrs) then I will get 2 and 4 pulled.

One little issue is that one cannot measure oil burn on the same day i.e. before and after a flight because the oil takes a long time to run back down into the sump, so the true level is not visible till the following day. That’s if you want to do it accurately.

Borescope ?

It’s going to be difficult getting any meaningful oil level results from only 1 or 2 hours flight (unless of course there is a really major problem).

My engine normally uses 1 qt per 3/4 hours and the level on the dipstick is not always consistent, fluctuating by 1/2 qt or more (I sometimes wonder whether oil does not always drain down properly from the upper galleries or prop) making it hard to spot a trend.

10 hours is the usual period to spot a difference.

The strange thing is that on the LGAV-LGML, LGML-LGSK, LGSK-LGKR flights I got low oil burn. The feeling I get is that oil burn correlates with altitude, or (equivalent) power output.

It’s the sort of thing which you may not notice unless you are looking for it. And very very few people fly at high altitude – excluding the EuroGA regulars of course

I have ample evidence that oil takes a lot of hours to drain back into the sump.

One firm I spoke to about pulling cylinders didn’t know you have to use the dummy clamps to stop the crankshaft bearing sleeves rotating, which I found absolutely staggering. That is the biggest problem I have here.

I just changed out 6 new cylinders on a TB21. The reason was Lycoming recalled the cylinders and sent all new kits and paid labour.

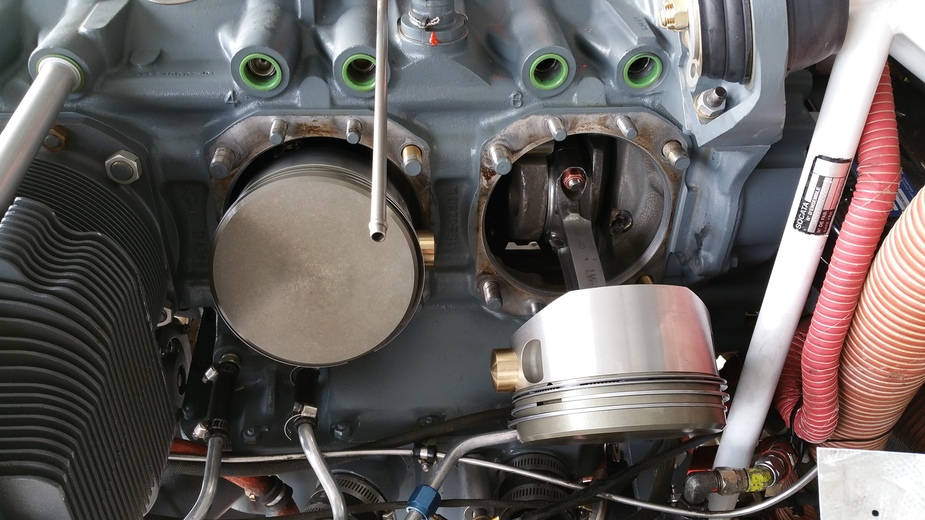

Changing the cylinders on the Lyco IO-540 is much easier than the big-bore Contis and it is NOT necessary to rotate the cranshaft when doing so.

The way I did it was to pull cylinders 5 & 3 at the same time, then install and torque before removing cylinder 1 . I then moved to the other ised and puled 6 & 4 at the same time, installed those cylinders and re-torqued before finishing with # 2.

Using this scenario, there was no need to even budge the crank wit the cylinders off which is the big danger.

I’ll post some photos in a sec.

ps: borsecope ???

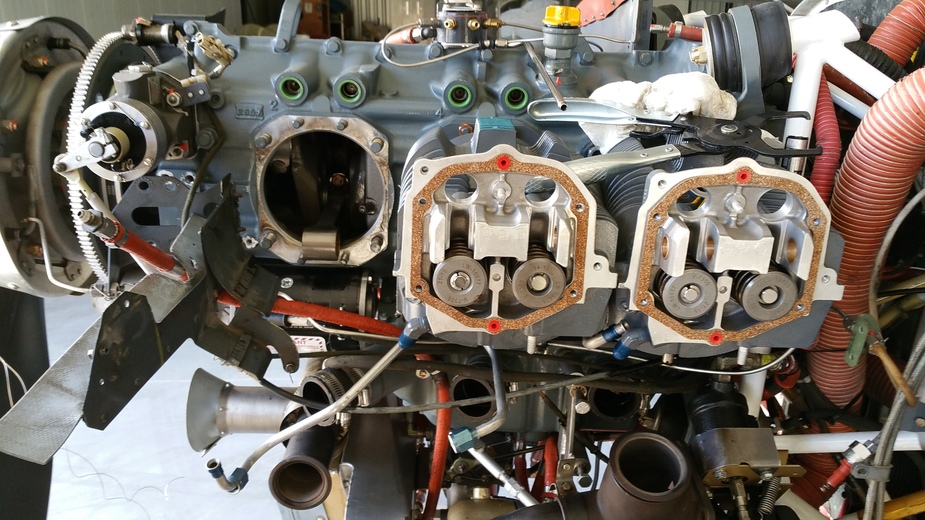

Here’s the photos of 2, 4 & 6 :

I have noticed that oil consumption increases with RPM (which I suppose makes sense). If I run higher RPM, either to go faster against a headwind or to maintain power at altitude, then oil consumption increases markedly.

Valve Guides? We just had out TIO-540 pulled today (burning lots of oil and excessive smoking on take-off). First looks imply the valve guides are worn.

In that case you find a lot of crud under the rocker covers and traces from exhaust. Also you would get sticky valves, not burn much oil as the deposits sit in the valve guides and seal them.

Unfortunately I know more about sticky valves on Lycomings than I ever wanted to…