My engine was taken apart in the USA and I have some good info and a good data point for an IO540-C4 which was frequently flown at FL200 and up to FL210:

The cylinders looked as I expected them to. The exhaust guides were worn

past service limits and the exhaust valve stems had .0015 thousandths

wear. This is completely normal on a high time engine in fact. Ring too

showed a normal wear pattern. To my eyes, you seem to have a very good

handle on how to treat a Lycoming engine.

I didn’t see anything that alarmed me to a oil consumption issue but

then again I didn’t dissect the rings with a microscope either. There

was no corrosion in the engine other than a slight amount on one of the

conrod beams. All in all a very clean engine core. While the cam will

need to be re-ground, it is not because of corrosion but standard

practice.

So… the high oil consumption – which was temporary, and was solved with some Mobil 1 0W20 in the last 5hrs of a service interval, repeated twice – left no permanent trace, and there was nothing wrong with the piston rings.

My conclusion, as previously posted, is that if doing these extended flights at the low power settings, one needs to intersperse them with some higher power low level flying. I normally do that naturally but on that occassion this didn’t happen.

I have an exchange engine now, just installed. Some details here

Peak EGT, slightly LOP maybe.

Are you not operating LOP ?

9 hours, and Yes, historically.

1 in 4 to 1 in 5, probably, allowing for the way most people account for oil loss i.e. they start at say 10 and do the service at say 7, account for the 5 they added, but “forget” the 3 (10-7) which they should also have accounted for

How many hours on those plugs ?

I’m still surprised by the amount of lead build-up on some of those plugs yet the top was has none …

IIRC, 1qt / 4hrs has been the norm since the beginning of your trials ?

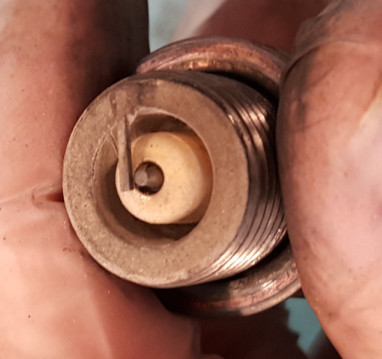

Here are the bottom plugs, after 8 more hours on Mobil 1 0W20:

and the oil loss is down to 1qt in 4hrs.

Question. Why does automotive detergent oil “clean” better than aeromotive detergent oil? Are they (or should they) not equally “detersive” (is that a word)?

Why would auto oil leave deposits more than aero oils? If anything with the amount of R&D that goes into auto oils I would expect them to be better?

Peter wrote:

The high power runs were only partially successful – as Aviathor wrote above.

And how do you know ?

Seriously, with such short sample cycles between the power runs and the Mobil 1 “experiment”, establishing any reliable cause & effect data seems unlikely.

The high power runs were only partially successful – as Aviathor wrote above.

Peter wrote:

Also I think the reduced oil loss during high power flights was illusory because the compression ring acts partly as an oil ring, and reduces the oil burnt.It also itself seals the combustion chamber better so the crankcase pressure is reduced so oil loss due to oil mist going down the breather is reduced.

Well that’s not really what I think is going on .

The high power runs clean out the carbon build-up from the long low power flights. Kinda like what you believe the Mobil 1 might be doing.

At any rate, any real change can only be measured over multiple flights averaged over multiple readings.