This may be of interest to someone who needs to renew/repair his.

I used the AAC-1000 material from Merlin Motorsport.

It was glued with Scotch-Weld 1300 L TF contact adhesive which is rated to +150C. It is really strong stuff but takes a few days to go off totally. One “aviation official” supplier is here and there are better ones. This one is toluene-free (TF) and masochists will prefer the 1300L version

Clean off the old stuff as far as possible. Not easy, but if there are any bubbles you can cut into them with a knife and use these weak points to peel off the rest. Mask off the areas to be covered with the adhesive

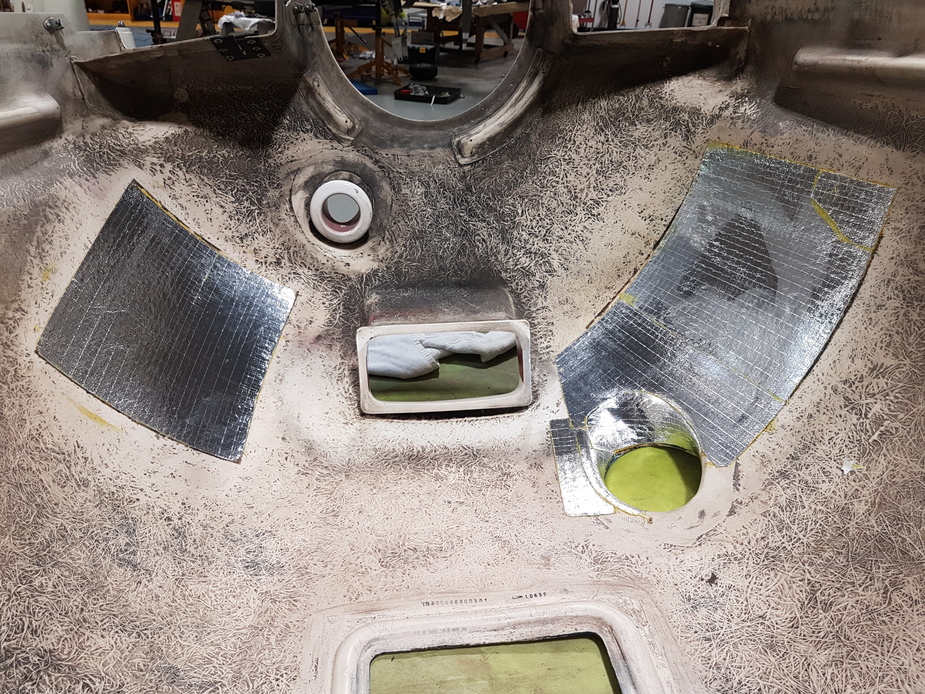

Cut out the pieces – like a jigsaw

Glue them on, pressing hard to make sure they follow the contours, and leaving no air gaps. You get only one go at it; if it has not worked out you have to quickly rip off the piece you have just stuck on and cut out a new one

For best longevity, seal the edges with PR1440 or similar 2 pack hi-spec sealant

Looks a quality job.

Nice.

Remind me again….when is your aircraft up for sale? Just in case. ;-)

I would look at Zircoflex for this application

Is it better than the above stuff?

I never found any material which can be formed into 3D shapes. I don’t think it is possible with anything covered by a metal sheet. Only some kind of corrugated material could be thus formed.

Peter

I am good no to have a look at Zircoflex later this week and will pass judgment when I have the product in my hands, other products from the company are highly rated in the motorsport business so I think it deserves consideration for this this application.

My last set of cowls had some heat protection but it peeled off quite quickly and was of poor quality and as the latest set of cowls from the manufacturer have come as a rough set of mouldings it seems to be up to the customer to sort out all the fasteners, fittings and protective finish.

It would be good to compare materials. I have lots left over. I can post you some.

I will be picking up the Zircoflex in the next few days, I will contact you when I get my hands on it.

Knock, knock; @A_and_C – what is your verdict thus far?

Any thoughts on using the “kevlar” stuff from the high performance car tuning shelf?

Has anyone fixed / replaced their cowling heat shields recently and can share wisdom (materials used, afterthoughts, etc)?

@Peter – is the adhesive really sufficient? The 300F limit seems a bit low, but I’m more than happy to be wrong. Any alternatives that might be better or as good but easier to obtain?

The stuff on my M20K has deteriorated enough that I want to replace it before we put the cowling back on, so I’m especially looking for (good) stuff I could reasonably source in the EU within a week.

A type-specific forum recommended this, from Aircraft Spruce – it is listed as being resistant up to 1100F continuous, which is more in line with the EGT temps than 300F: http://www.aircraftspruce.com/catalog/eppages/kevlarheatshield.php?clickkey=2351393

Hi TMO !

Due to many delays and me having six months off flying while the medics fixed my landing gear I have very little air time with the Zircoflex as of yet.

What seems to be essential is that it is applied to a very clean surface and the edges are sealed with a good high temp RTV ( Dowsil 736 ). The real enemy of these heat shield products is oil ingress and keeping the oil out is essential.

I do expect the Zircoflex to be successful I have it fitted underneath the seat of a motorcycle to shield from a very hot exhaust and it works very well.

300F is fine. Above the fibreglass cowling will be damaged anyway.