I’ve run an analysis of Engine Failure data for all Cirrus aircraft in 2014. The fact they are Cirrus is irrelevant, except for the fact fleet hours are available (estimated at 1m in 2014) and accident investigations have access to a quasi-black box data recorder most times for this aircraft type. It is highly likely that in my personal interpretation that I have not analysed this correctly, have omitted data, misunderstood something etc, so maybe we can collectively correct it.

Here’s what I’ve gotten: there were 9 engine related accidents in 2014

06/01/2014 F-HAPH – failed 200hours after cylinder changed.

06/01/2014 N583KM – overly rich mixture, student on unauthorised flight to mountain airport.

03/03/2014 N1645S – couldn’t find report, assume full failure

01/04/2014 N450TX – mixture too lean for landing

09/07/2014 N22WX – mechanics failed to torque throttle cable 73hrs prior

01/09/2014 N903SR – NTSB suggest cycled mags would have restored power

22/10/2014 N242MB – 770hrs after factory overhaul, no noted mx since

06/11/2014 N813JE – through bolt torque after cyl replacement 27hrs prior.

28/11/2014 N227RR – faulty sensor.

In the above 9 ‘engine failure’ scenarios, 5 were mechanical breakages beyond the pilots control: F-HAPH, N1645S, N22WX, N242MB, N813JE. The other four failures, it appears the NTSB had an alternative view on. Obviously, Cirrus failures are better reported due to the use of the chute BUT partial failures where sufficient power was available to get back to the field are excluded. Events outside of the NTSB database on aviation-safety.net are included.

The above data suggests 5 catastrophic engine failures in 1m fleet hours flown in 2014, or 1 engine failure per 200,000 hours. If the above is wildely inaccurate, I will delete the thread, so please advise.

note: I have used 2014 as most NTSB probable causes are out so one can dig deeper into the root cause.

DMEarc

DMEarc wrote:

The above data suggests 5 catastrophic engine failures in 1m fleet hours flown in 2014, or 1 engine failure per 200,000 hours

Interesting. It shows piston engines aren’t all that bad.

Were the “catastrophic engine failures” without any warning symptoms? A rhetorical question, which I’m not expecting DMEarc to answer. The answer may be in the NTSB reports.

We’re all the same engine manufacturer and type?

I’ve looked at the reports. 19 Cirrus in 2014. Suggest dropping N1645S as it isn’t mentioned. None of the US engine failures had adequate warnings.

Despite the NTSB, I’d keep N903SR as a catastrophic engine failure. With the mags gearing mashed up, that makes 4 US aircraft engine failures due to poor assembly.

N227RR is interesting. After the pilot reduced revs, he says he was unable to gain them. Does the FADEC prevent increasing revs if there is no indicated oil pressure? We flew home no problem with a Continental O200 oil pressure gauge problem, with oil temperature staying normal.

Also interesting that the 2 acceptable height parachute deployments caused less damage than the one successful forced landing.

Maoraigh wrote:

N227RR is interesting. After the pilot reduced revs, he says he was unable to gain them.

Report states that the oil pressure fell to zero, and the power reduced itself to zero.

“During cruise flight, about 9,000 ft mean sea level (msl), the oil pressure indication decreased to 0, which resulted in both audible and visual warnings. The engine power then reduced to idle, and the pilot’s attempts to restore engine power by moving the throttle were not successful.”

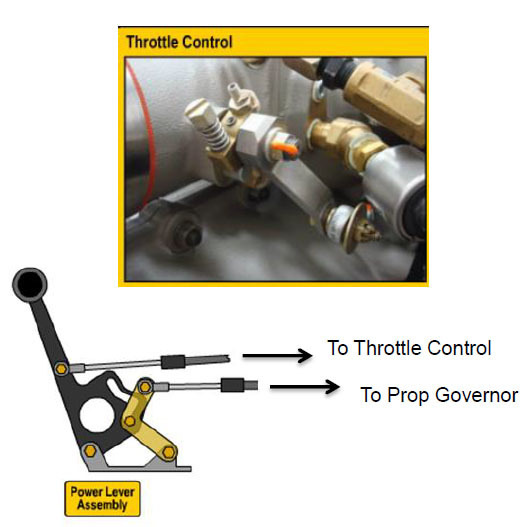

Cirrus SR20 and 22 do not have FADEC but a mechanical power lever interconnecting throttle and RPM:

So he could increase or decrease power (if the engine was working properly) with no regard to indications.

Ga90,

The NTSB probable cause is located here

It states:

A postaccident examination and test run of the engine revealed no evidence of preimpact mechanical failures or malfunctions. Further, normal engine oil pressure was noted during the engine run; however, subsequent examination of the oil pressure transducer revealed that it was faulty and would have resulted in an erroneous oil pressure indication, as reported by the pilot

the loss of engine power was consistent with the pilot’s operation of the engine controls not with a mechanical malfunction or failure of the engine

The National Transportation Safety Board determines the probable cause(s) of this accident as follows:

The pilot’s improper decision to descend the airplane at an airspeed greater than the published best glide speed following an erroneous oil pressure indication, which resulted in an off-airport landing. Contributing to the erroneous oil pressure indication was the faulty oil pressure transducer. Contributing to the severity of the accident was the pilot’s late deployment of the ballistic parachute system.

Therefore, it sounds like there was no mechanical malfunction.

Thanks, overlooked that part somehow.

But still, wondering then, why couldn’t he get the power back, if only the indication was wrong? Like the NTSB says, “pilot’s operation of the engine controls”? Forgot to readjust mixture after attempting to obtain power with throttle in a descent?

I don’t think that one counts as an engine failure. The pilot got a zero oil pressure reading, shut the engine down to idle, started a glide approach, got too low, and instead of opening the throttle he pulled the chute!

The Probable Cause report suggests more pilot error.

If he had checked his oil temp…….