Both the certified and the ULM version of the Bristell, 912S (ULS) have the same airbox with carb heat.

I imagine that nothing they suggest doing in operation will actually have any effect on engine CHT, which is the measurable parameter that would indicate thermally “stressing” the engine in a way that could lead to failure. The other related way that can occur is detonation

Could excessive EGT cause damage to exhaust valves though?

Regarding carb icing. I have not yet heard of a single case of carb icing in a Rotax (I have heard some stories, but no clear evidence, not even from Rotax themselves). I think one factor can be that Rotaxes usually don’t have carb heat. The way it usually is done, is to take the air directly from inside the cowling. This air usually has some temp above ambient (sometimes well above on the ground), but nowhere near the temp of carb heat air. If carb heat is installed, the unheated air is fresh and cold ram air. Often, but not always, a “air box” is installed. This box also work as a heater for the air.

I think I read somewhere that certification specs warrant carb heat on all carb’ed engines. Whether they actually ever would ice up, is irrelevant in this case.

Like le Sving we use duck tape in winter and take it off in summer. This summer we have been operating at ground temperatures of 30° to 40°C without problem on any of the Rotax engines.

We have had problems with the DA40D with the 135hp Continental and it is grounded during very high temps until we find out the cause of the overheating.

On the Rotax 912 powered Super Guépard we would have no way of following that SB. We simply don’t have the guages or levers. It is a very basic machine with a constant speed prop.

Between our Super Guépard and the gliding club’s Rotax powered Icarus we have averaged around 200hrs + per month since May with no overheating problems.

What has changed in the last couple of years that was not there before and could trigger the higher number of events later?

I would think mogas composition (which is BTW also seasonal), but since Avgas aircraft are not immune, there must be something else…I dont believe the crap about incorrectly installed fuel lines, since I don’t think everyone would have agreed in the last couple of years to install them incorrectly across different types…

Perhaps nothing actual has changed, and the only change is the increased reporting?

Antonio wrote:

Perhaps nothing actual has changed, and the only change is the increased reporting?

The pilots have probably changed. How many have actually read the Rotax manual? You can tell by the way they “burp” the engine to check the oil. Seems like fewer and fewer to me.

Antonio wrote:

across different types…

But does this problem affect different types equally? Some aircraft do not occur in the list from the Swiss CAA, e.g. the Evektor Sportstar. Of course I don’t know the relative numbers of different aircraft models using Rotax engines.

LeSving wrote:

ou can tell by the way they “burp” the engine to check the oil. Seems like fewer and fewer to me.

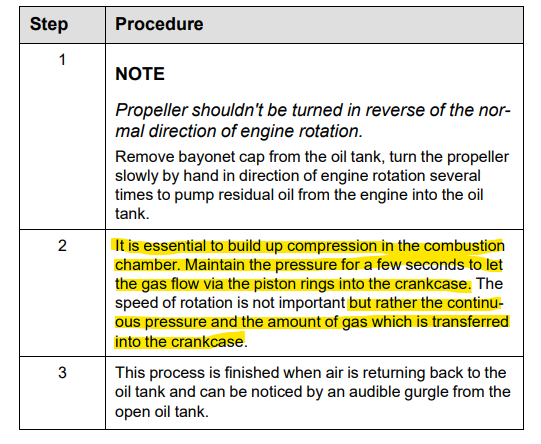

Can you “burp” it in different ways? I was taught to turn the propeller by hand (in a continuous movement if possible) until the burp is heard. Are there other ways?

(Serious question, I have very little experience with Rotax engines so far.)

Airborne_Again wrote:

Are there other ways?

Well, the “Rotax way”  That is, do it according to the manual.

That is, do it according to the manual.

Most people just flick the propeller mindlessly because “that’s what they have learned”. From who? If you do this correct, you will get it to “burp” in the fraction of the time. The important thing here is that it’s a true tell sign if someone has read the manual. Rather peculiar in fact. This is the only check in the pre-flight check list of every single 912 series engine ever produced, and almost no one has bothered reading it. Perhaps they have read it, but still would rather go with “what they have learned” instead of doing things the way Rotax explicitly say in their manual. This is probably more likely in fact. I’m wondering what else they have “learned”.

There’s something I don’t get.

From the Bristell bulletin:

When transition from climb to cruise is made, first the RPM should be reduced – NOT the manifold

pressure.

This goes completely against what I was thought re. constant speed props, RPM and throttle. I was taught, when reducing power, always reduce throttle / manifold pressure and then RPM. What you want to avoid are situations with high MP and low RPM, since they stress the engine.

Now Bristell comes out and tells us to do exactly this. I don’t fly Bristells, but Katanas, but I guess they work the same. It’s also a Rotax 912 with constant speed prop, Climb is at full throttle and 2400 RPM. It would go completely against my training to pull RPM to cruise, while maintaining full throttle, when levelling off after a climb.