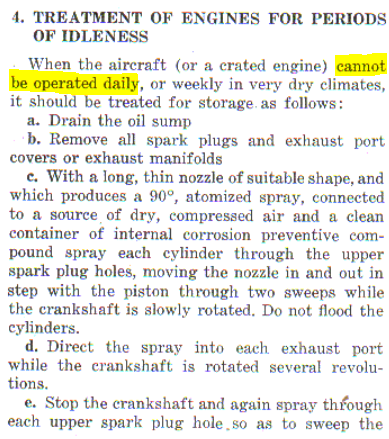

Just saw this in the A65 manual :

and it goes until m), to be repeated every 30 days

I think that advice is based on GA operations with adequate funding i.e. nowhere in Europe

But, yeah, this is priceless. I would print it out and show it to the police when flying in Tier 4 lockdown

Well, published in 1944, for sure they had more elbow grease available

My A65 powered plane (now sold) did 500 hrs between March and October of 1946, per the log book, an average of more than two hours daily. There was a lot of flying going on with A65s at that time, mainly funded by the G.I. Bill

My A65 engine did accumulate a fair amount of internal corrosion after I bought another plane and it was when not flown regularly, visible by removing the oil sump.

It is hard to prove that as the cause, however.

Corrosion can be dangerous on stressed parts e.g. conrods on which the tolerance is zero.

A cylinder sheered off at its base on a O-235. Mmmh

The crash brings the question of maintenance in a coastal environment and maintenance best practices.

Mike Busch refers to this kind of failure after cylinder replacements gone wrong. (example at 1:12)

My thoughts :

Those reports seem to pile up and nobody cares about changing something in mx practices. OSAC or at least BEA should watch Mike’s webinars

Why? BEA do not apportion blame.

Secondly it states the DGAC wanted to introduce measures but EASA refused.

Lycoming took action

A programme of inspection was initiated/ published.

Guidelines were introduced.

I realise that some people on here think the sun shines out of Mike’s rear end, but seriously I think everyone can see the problem here and watching such a video would not have cured what happened or stop it happening in the future.

Could corrosion create or contribute to such a failure ?

It could but would have to be pretty bad. However, one would notice anything like this on a 50hr check which is normally a very quick job, with a visual check at best. Almost nobody borescopes cylinders, ever, and even less so on a 50hr check, but that shows up only the cylinder wall above the piston, which would normally be free of rust (on an active aircraft) due to the rings scraping off the rust

OSAC likes to have a cylinder removed (every year or so) on high time engines to visually check for corrosion. It could have been put back badly.

Indeed. Cylinder removal is a very risky job. It needs a careful mechanic to do right, and evidently they aren’t all that common.

But this is little to do with a “high time” engine. It is to do with an infrequently flown engine.

Would oil analysis have caught this cracking before it seered the cylinder ?

No, unless there was a bad case of general corrosion inside the engine, so the weakness started from inside. That can happen e.g. around 2000 Socata sold a number of TBs with heavily corroded engines, due to improper storage. I got one of them, as did others

I realise that some people on here think the sun shines out of Mike’s rear end

I think that is unfair. On EuroGA we have a high % of aircraft owners, which ought to correlate with a high level of maintenance diligence. In most European countries you have a low % of owners and most activity is school/club rental, where “somebody else” is “supposed to” look after stuff. Mike Busch comes from the US culture which has a high % of ownership and a high level of interest in looking after stuff. There is a lot to learn from him, and each new generation of owners would be well advised to read absolutely everything he and Deakin have written.

Of course Busch makes money out of this, but so does almost everybody who has a decent social media profile. Look at all the youtube material; it’s nearly all people trying to make money (and nearly all failing). Nearly all of the high profile flights are to make money (for a “charity”, of course  ). The APS courses are absolutely to make money, and I do think they over-complicate the subject. But Busch is good old simple stuff. His videos are painful to watch because the real message is brief. And I know much of what he says is usable only with an N-reg because it runs against the revenue-focused European maintenance industry…

). The APS courses are absolutely to make money, and I do think they over-complicate the subject. But Busch is good old simple stuff. His videos are painful to watch because the real message is brief. And I know much of what he says is usable only with an N-reg because it runs against the revenue-focused European maintenance industry…

I wasn’t criticising Mike Busch or his videos, what I wrote was a response to a posting regarding the forced landing at Quimper, in particular, and other such comments which have been posted following other incidents.

Regarding the Quimper forced landing, nothing in Mike Busch’s videos would have made any difference when we see that the reason behind the problem was not lack of knowledge about what should have been checked but the fact that the appropriate checks were not carried out.