The IO540 TCDS is here.

For the -C4D5D, page 2, the capacity is shown as 12 normally and just 9.25 with 30° nose up or down. I cannot see a minimum level in that document but (I think we discussed this here before) the Socata POH gives a figure around 6.

as 12 normally and just 9.25 with 30° nose up or down

We use 9 minimum for the T67M260 Slingsby Firefly and it spends very little time inside plus or minus 30o pitch range, but does have an inverted system.

Air-oil-separators are evil, stay away from them. Attach a small glass bottle to your crankcase breather and go on a longer flight. Then look what you have in your bottle. Imagine that stuff will be fed back to the crankcase which is what an air-oil separator does. Also these devices have very interesting failure modes and installation mistakes that can ruin your day. Never ever.

They are not evil. What comes out of the breather is blow by gases mixed with a mist of oil. Water and CO2 mostly and some NOx and other stuff. Most of the gases just goes straight through the separator and out. Some of the water vapor condensates on its way to the separator and get mixed with some of the oil to a nice emulsion. A return line to the sump sends the emulsion back sump, or you can just collect it and manually drain it. Sending it back to the sump does no harm to the engine, it just get vaporized again and mixes with the gases. The amount is negligible in any case. When the oil level is high and you do some maneuvers, larger slugs of oil gets thrown out the breather. That’s when the separator starts doing its job. Instead of just throwing it out, it is collected and fed back to the engine.

IIRC, aircraft are certified to fly with 1/2 the maximum oil. So a 12 qt aircraft will be fine with 6.

The min oil requirement comes from the engine manufacturer and the certification regime requires the minimum engine oil level to be twice the amount the engine needs to operate within the approved environment (bank/pitch, etc.). The sump capacity also comes from the certification regime, it is min level + max allowable oil consumption * max endurance.

Sure, but then the better question should be: why does it need 6 quarts while other engines of similar design and displacement need only 2 or 4 quarts to run properly?

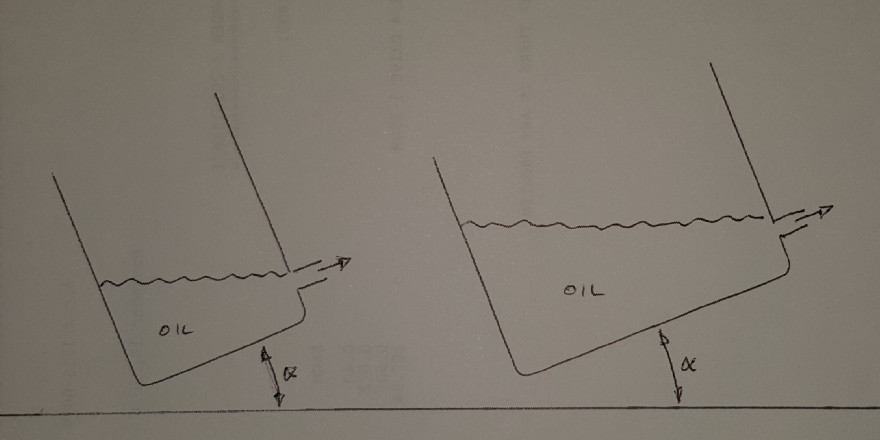

A longer sump needs more oil for a given range of pitch angles, before the inlet to the oil pump gets unported?

Then: why the longer sump?

I am very interested in the various comments about oil degrading after 30 ish hours.

I have a quick drain on the sump of my Piper PA28-181 it would be very easy for me to change the oil every 25 hours to prolong engine life.. I want my engine to run well past 2,000 hours in fact, I’d be happy to go for 3000 hours if it behaves properly. So far it’s at 500 hours and in very good condition. I have a hose I can pop on and I can do this job without removing the bottom cowling. I am thinking of only changing the filter at 50 hours as usual.

Can anybody see any issues with leaving the filter on at a 25 hour change?