LeSving wrote:

Rotax parts from “authorized” Rotax dealers are expensive. I have seen a 5x variation in cost of oil filter for instance (the exact same OEM filter). Not often you replace gaskets and seals on a Rotax though.

On the Europa I found the correct sized O rings instead of buying the Rotax ones, of course this saved a lot of money but it took me a while to find the correct sizes.

My ULPower 260i just gives the sizes of all the O rings in the manual, so you just go buy the correct size parts for pennies.

Reading your posts with envy. In my opinion the early RVs are the sweetest to fly. That’s what sets them apart from the later models. Congratulations and happy flying!

Dan wrote:

and none of those laser cut parts…

with all due respect…. If I understand correctly, results of fatigue testing of properly manufactured laser cut parts indicate that they are at least as good as pre-punched ones.

Lovely project. Congratulations.

I normally quickly glaze over on the technical threads, but found this and the Europa restoration very interesting

At this point the plane was disassembled for the inspection. I’d had a lot of help from the LAA inspector Adrian throughout this process, and he visited 5 or 6 times to check various things, give me more jobs to do and help with various items like timing the mag and ignition.

This process felt a lot more like an annual which was reassuring. In my opinion, most LAA inspections and the resulting “permit to fly” are a formality and have little to do with whether the plane is airworthy or in good mechanical condition. It’s absolutely up to the owner to make sure their plane is in flyable order. I’m happy with this as I enjoy the tinkering just as much as the flying, but for those who like to pay someone else to do the maintenance owning a homebuilt is perhaps not the best idea.

I also had help on hand in the form of my Labrador, but he mostly resorted to antics such as stealing my lunch.

After the wiring was complete I 3d printed a clamp to fill the hole in the panel where the old Garmin 296 was. The ram mount fits to this and puts my iPad mini in a good position, on the to do list is to make a cooler for the iPad mount.

I also cleaned the leather seats with Colourlok cleaner, they turned out OK. Oddly I find most leather seats in aircraft never seem to be cleaned, how many adverts have you seen for planes with shiny, filthy leather? It takes 5 minutes to clean them…

Anyway, following a final inspection I put everything back together and Adrian did the permit flight test with me in the right seat. It went well and the plane handled beautifully, exactly as I’d imagined. The permit test flight is a good exposure to a new plane as one explores stalls in different configurations, a vne dive, various performance tests and handling tests.

It took a week for the permit to fly to arrive, and it arrived on a day with beautiful weather and low winds, which has been a rarity this summer. I immediately hopped in the plane and flew it about 4 hours, 6 flights and all went well. These things handle so nicely and are serious fun to fly. Especially fun is intercepting your slow rotax powered friends. Ground handling is benign except for the springy gear, there is no need for type specific training if you have relevant experience in taildraggers and aircraft of a similar speed range. It’s easy to fly.

So far I’ve found it to top out around 163kias with everything forward, and leaning at to 22lph gives 130kias. 26lph gives 140kias. I’m happy with that economy, it does have a Lightspeed EI fitted in place of one magneto which perhaps helps. Originally I was after a slider canopy variant, and whilst I think this is more practical than the flimsy tipper canopy, I’m happy with my choice. The unobstructed view is amazing, especially for formation flight.

You’ll notice that the #2 egt has died here, it turned out to be a dodgy probe. I emailed the UK MGL distributor at 7pm on a Tuesday evening about this, and got a reply within 15 minutes saying he’d dispatch a new one to me which duly arrived on Thursday. They may be cheap avionics but the service from the UK dealer (parts4aircraft) has been excellent.

For now it’s flying, so I’ve got a few more jobs to do which I’ll post about as they happen.

Here’s one of those peaky Rotax-powered RV’s next to your 6, back in 2020.

Time for an update, and a request for opinions…

Since the permit was issued in August the RV has accumulated about 85 hours, all trouble free except for the vacuum pump committing suicide. The now useless vacuum AI was replaced by a G5. I’d have flown it more if the weather wasn’t so bad in the last few weeks.

It’s been south, to Annecy, and north, to Glenforsa. It’s enormously fun to fly, light and precise on the controls yet stable. I see why they are so popular.

I tend to cruise at 130-135 IAS and 23-24 L/hr. Whilst the fixed pitch prop still provides great performance, the current prop is in need of refurbishment and may need to be replaced entirely. It’s seen better days and the previous “refurb” job evidently involved some aerosol paint which has done nothing to protect the wood.

The obvious thing to do is to fit a constant speed prop. Then I’ll have 2700rpm on takeoff, instead of 2200-2300. It would add some weight to the nose which will help with the aft CG. To convert to constant speed I need two things: a load of money to waste and an engine that can definitely accept a CS prop. The first one can be worked around, the second is not so easy (well you can always fix it with more money, but an engine rebuild AND a CS prop is pushing it). Lycomings can be configured a million different ways it seems, so following much research it seems that the O320 engine needs the following to operate a CS prop:

You also need the crankshaft plugs in the correct place but this is easy enough to change, as per Lycoming Service letter 1435

The only one I can’t check is the last one, but everything else is there. The overhaul parts list shows the correct front bearings. The engine was originally an O320-E2A in a Rallye, but was converted to the higher compression -D2A at overhaul. From what I can tell, because my engine was a hollow crank and it has all the other features for a CS prop, I should be fine. I believe only crankcases for a solid crankshaft engine will have the hole.

I’ve seen other engines that were definitely never intended to be constant speed, such as not having the hole in the crankcase for the governor oil feed, or the machined accessory drive pad. Given that my engine has all of that, I’ve decided that I should be safe.

Researching available propeller options led me to this list. The options are more limited for an O320 than a 360.

- MT 3 blade: 16600 USD with governor, 40 week lead time – 42lb weight

- Hartzell 2 blade from Vans: ~ 13000 USD with governor, 12 week lead time – 57lb weight

- Whirlwind 300 3 blade: 15600 USD with governor, 8 week lead time – 36lb weight

None of them are cheap, and the 10 month lead time on the MT ruled it out completely. I’m way too impatient to wait nearly a year for a propeller to show up. Whilst the MTs have some great features such as field repairability, I have also seen lots of MTs with bits missing. Perhaps the UK climate isn’t so kind to the wooden blades.

The Hartzell is heavy and the available Hartzell for the O320 is the old paddle design, not the blended aerofoil version. I didn’t want to spend so much money on a 1950s propeller design, plus I wouldn’t gain the low vibration of a 3 blade.

Whirlwind make a carbon 3 blade that weighs only 36lb, is apparently as smooth as the MT and has no speed penalty vs a 2 blade, but with better takeoff and climb. The risk with the Whirlwind is that it may not be as robust as say a Hartzell, but as with most products of any kind, you can find complaints and problems about any brand if you look hard enough.

Following further discussion with Whirlwind, they said I could have a prop shipped in December, which meant I could tie it in with other work. I’m installing an autopilot (detailed below) which counts as a modification with the LAA, and the modification procedure is expected to take around 10 weeks. That means the plane will be grounded for 10 weeks. I expect a similar timeframe for the propeller, so if I can get the prop before the end of the year I can do both sets of paperwork/delays at once. As a result of all this, I’ve ordered the Whirlwind.

I also have sitting in a box:

- G3X touch 10.6" display

- GMC507 AP controller

- 2x GSA 28 servos

- G5 (already installed to replace failed vacuum AI but will be moved to a standby position)

- GEA 24B engine monitor

- Magnetometer/OAT/AHRS etc…

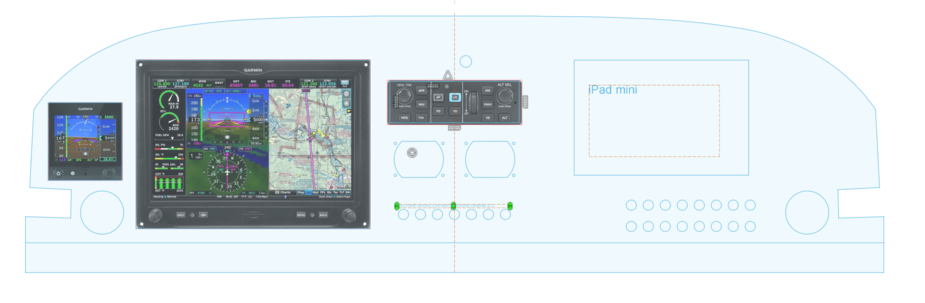

Here’s a few options for the panel

This is currently my preferred option:

And an overlay onto the current panel:

On these drawings, the vertical yellow dashed line in the middle is the centreline, and the small circle near the top centre of the panel is for the emergency canopy release, which I want to leave where it is. For now I am keeping a single Trig com, the Trig Mode S and I don’t want to add a second G3X display or an IFR GPS.

Which layout do you prefer and why? Also any input on the CS prop conversion would be appreciated, in case anyone here has some obscure knowledge on potential “gotchas”.

Next is a colour change. I’ve no interest in repainting the plane, so I’ve been planning a scheme using vinyl highlights. This is the current contender:

With this colour of blue Vinyl. The silver stripes are TBC

Re: PROP – I’d be scared to order anything from Vans. :)

And another one – as this is a two-seater, you don’t need a certified prop, right? What about an IVOPROP?