Affirm, that is the old reject, with corrosion pitting visible on the 1st pic. The 2 areas where the alodine has been removed in the 2nd pic, is the area which is specifically eddy tested, so I’ve been told, though the process itself was outsourced.

The eddy current inspection will be looking for cracks.

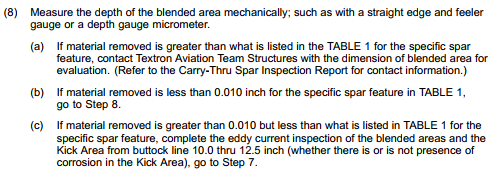

The visual inspection for corrosion will drive a blend-out of corroded areas. There is a limit to the blendout depth. If exceeded, then you need Cessna evaluation. The rejection should come as a result of such evaluation.

In this case, it is likely this partituclar rejection (like all others) was due to excessive depth of the pitting (see the deep blendout in the lower RH side of the pic) . I am not aware of a single cracked 177/210 spar other than the one which drove the SB+AD. Unfortunately on some aircraft this area was neglected in annual inspections over the years due to bad access resulting in a number of aircraft now failing the inspection due to corrosion.

Newly manufactured replacement carrythrough spars for the 210 series have been available from Textron in the past few years. I am unsure about the 177 series.

Following is an extract from the 210 SB, but the 177 should be equivalent.

.

Coming back to the OP, if an aircraft has satisfactorily passed this inspection and ensuing corrosion protection, this will not be an area of concern on the relevant airframe.

I have flown both the fixed and RG 177’s and have many good things to say about them. That said, as any legacy airplane these days, airframe contrition is everything.The issues with the center spar are very well documented by Cessna, and now, fairly well understood by industry. I haven’t been involved with a 177 spar repair/replacement yet, but I have been involved with several 210’s. One thing to bear in mind is that if the airplane has any structural or aerodynamic mods (a STOL kit being a common example, and for 210’s tip tanks or speed brakes), Cessna will not provide any data for consideration of a corrosion repair exceeding their published numbers. Thus, although I’m generally a STOL kit fan, I would not buy a 177 with a STOL kit installed, in case future Cessna support were needed.

took a couple of pcs of the spar… this one is definitely junk

Hm. Somewhat scary to realize i flew my family in that stuff…