you are going to get way more differential with pressure rather than suction.

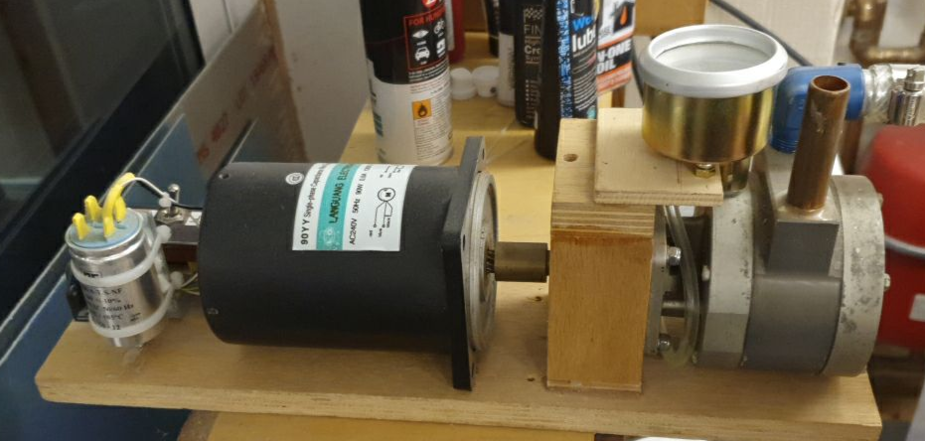

This, built for spinning up vacuum instruments

should do about minus 13psi, with zero risk, while, yes, I could put plus 50psi into the panel, which won’t end up as 50psi due to it leaking through all the clear holes, while risking blowing some pipe joint which would be an absolutely massive gigantic horrible job to fix, and that’s assuming I will even know it blew, because the panels all leak via the little holes, so there is no way to pressure test anything.

Can you not poke them with a needle?

They are hundreds or thousands, they are barely visible, but it is a good point whether just using emery paper or a fine wire brush might do the trick. It is possible somebody just swiped a handful of lacquer or silicone sealant or some such on the panel.

Have you anything like this 60x or 90x magnification – take a good look

This could be handy to have a close look – see video

https://www.amazon.co.uk/Carson-MicroBrite-Lighted-Pocket-Microscope/dp/B00LAX52IQ

Another one – 1000x !!!!

https://www.luxuniversal.co.uk/products/digital-microscope-3in1-usb-1000x-magnifier-hd-video-camera

I had a go today with the super vac pump. I was partially successful, clearing out maybe 50%. Unfortunately I can’t say which of several methods did it: the vacuum, a wire brush, lots of IPA on a rag, emery paper…

Also it is possible the blockage is internal. What could cause that? AIUI inside these panels is just a strip of some sort of foam.

I wonder if taping some plastic sheet over the good parts of a panel might force the fluid to the bad parts?

As I mentioned some way of safely blocking the good sections is bound to force the flow to the bad sections – just a case of how far do you go with this differential approach.

Are you able, for a similar reason, to disconnect the tailplane while all this is going on (will save fluid if nothing else).

Any merit in the high magnification technique to observe what might be going on down in those holes ?

I would mess with the plumbing as an absolute last resort for reasons mentioned. The magnifier would be interesting but a close look suggests the “blocked” holes look just like others.

I did another ground run yesterday and things looked a lot better. Then I did a flight and the stuff was coming out pretty well all along everywhere. It will remain a mystery but it could be that it just took a LOT of fluid to either clear the blockages, or just to fill up the internal “sponge” all the way along.

I will make a note to test the system every month from now on

Interestingly I now seem to have a stuck level gauge. It is reading 7.1 all the time  I have a spare, but it illustrates how careful one has to be. I will go back and fill it right up and then when using it in flight keep track of the times. The Annual is in January…

I have a spare, but it illustrates how careful one has to be. I will go back and fill it right up and then when using it in flight keep track of the times. The Annual is in January…

Overall, since the installation in Jan 2018, I reckon 75% of the fluid used was used up in testing the system! I need to sort out a cheap supply. The big batch of fluid I got from another pilot came from Far North Aviation in Scotland…

And it is clear that for ground testing one does need the gutters to collect the fluid otherwise it works out crazy expensive. You still waste the fluid coming out of the vertical stabiliser panel; no obvious way to collect that.

Things sound a lot better now – that’s good.

There is a guy (think in Germany) who has posted on this thread and others and mentioned he blends his own TKS look alike fluid from the basics.

It’s funny to reflect that perhaps 3/4 of all the TKS fluid I have used since the system went in in Jan 2018 (hundreds of litres) was used in testing the system / clearing out blocked areas

I guess the best procedure is to make a note to do a test every month, and run it for say 5 mins in flight, and do this really every month.

Or one could do a ground test, with the gutters attached, and recycle the fluid (through a filter; I 1-micron filter all the fluid I put into the TKS tank, anyway) although not sure how one could easily catch the stuff coming out of the vertical stabiliser.

OTOH, the tail has never had a problem so it does look like this all is 100% caused by ground handling: dirty hands, etc.

With those difficulties I would really like to know how many of the TKS installations actually work properly when owners do not take enough care and leave it to annual maintenance. Our plane has got boots and the number one risk is the metal fuel filler, especially if we do not operate it ourselves. So we only refuel with a big rubber mat which also goes around the leading edge.