There is a procedure which CAV told me about where a really high pressure (many PSI – can look it up if somebody needs it) is applied, to unblock problematic panels. So they can take a lot of pressure. The problem is that if it causes one of the nylon pipe fittings to loosen, you have a MASSIVE problem because they are behind the panel, inside the wing and completely unaccessible, and the panel is stuck on with 2 pack adhesive (in addition to any rivets), and basically there is a high chance of doing a lot of damage when trying to get the panel off. And anyway you will never know there is a leak; the wing will just fill up with fluid  And I doubt CAV have stock of TB panels, and may never have any again.

And I doubt CAV have stock of TB panels, and may never have any again.

I think I need to use the “local vacuum” method. Cobalt’s little suckers may well work

I am sure the whole issue is caused by airport staff pushing on the panels with dirty hands.

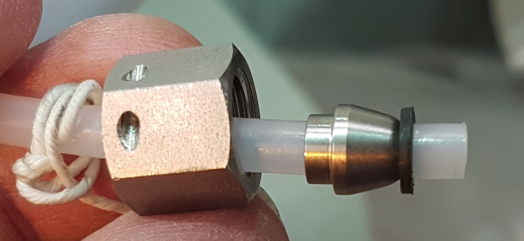

Yes, causing an internal leak would be a disaster. What sort of internal pipe fittings are they ? There was a system called Enots in the machine tool world for small bore lubrication pipes (Nylon). The connectors used a ferrule ring system like what is used in compression plumbing systems. They had a very high pressure rating – forced lubrication systems.

Perhaps some aircraft covers for the wings might be needed in future to avoid a recurrence.

They are ferrule fittings

but I am not going to do this because (a) accessing the feed end is a lot of work, and (b) most of the fluid will just p1ss out of the other holes in the same panel.

Vacuum, together with a suitable solvent (IPA is one of the permitted ones, but I will check) must work.

More pics here.

Aircraft covers, indeed, although they are a bastard to put on because of the training static drain wicks.

I’m not a trained aircraft handler, but would never have thought of the risk of blocking microscopic weeping wing holes in this way. Is it a known risk in the industry?? Many would not give it a second thought – just push on the leading edge. For low wing I would often push from the hips to spread the load – dirty overalls / dusty trousers etc. I’ve never handled a TKS wing.

Those ferrule type fitting will have a very high safe working pressure. I was suggesting progressive covering (plastic sheet) of the good panel section to increase the pressure on the bad section.

Much better if a more simplistic method could be made to work.

I’ve had this scare on my Cirrus, though it turned out the be a false alarm.

If all else fails then folks on the Cirrus owners club forums say you have to do the high-pressure flush, using a pressurised test cart. It is a recommended procedure so you’d hope that connectors etc coming undone wouldn’t be common. The system is pressurised to 60 psi.

The full instructions for the procedure (on a Cirrus) can be found starting page 17 of section 30-00 in the maintenance manual:

http://servicecenters.cirrusdesign.com/tech_pubs/SR2X/pdf/AMM/SR22/html/ammmain.asp

The test cart costs $$$ but at least one Cirrus owner has made their own for around £200 of parts. Basically a reservoir & filter all connected up to a compressor – looks pretty simple to build. If you need more details let me know and I’ll post more of my notes.

Dave

dublinpilot wrote:

Perhaps some aircraft covers for the wings might be needed in future to avoid a recurrence.

The clingy food wrap thing off a big roll should do the trick ;-)

Some put it over fuel caps when parking outside and expecting rain…

Please recycle.

I’ve seen pics of install shops using some plastic channel (similar to those use for gathering rain on the edges of roofs…what are they called? my English is failing on me!) underneath the LE of the wing and tail to catch most of the fluid and drain it into buckets. I seem to recall they stuck a tape just aft of the lower surface panel , L-bent lengthwise, to stop the fluid from running underneath the wing and forcing it down onto the channel. That way you can run your 100€ fluid-worth of tests every month cheaply. The problem is you have to keep them free of dirt and you have to ensure good filtering of the fluid for reuse. Of course if you dont have anywhere to store it at the airfield and have to set it up every time, it may not be worth it.

What I have indeed read everywhere is that you have to run it regularly and keep panels moist and holes freshly fed. Interestingly, I once tested those on a P210 that had been grounded for months, admittedly inside a hangar, and we carefully checked all panels and could not find any blockings. The owner said he had been using it every couple of weeks since install, regardless of need, while it was not grounded.