An FAA A&P mechanic working on an N-registered aircraft does not need any affiliation with anybody (including a repair station of any country) to install a part. Nor is he limited to particular GA aircraft or types of work – his A&P covers everything.

He can also be located within any building or business premises he wants, anywhere, while working under his A&P.

The only reason to go to a repair station of any country to have your GA plane maintained would be if you wanted to allow the possibility of personnel who are not FAA certificated mechanics to maintain your plane.

Peter wrote:

Say the FAA 145 doesn’t have a TB20 on their list, but there happens to be an A&P working there, and you bring your TB20 in, it will be that A&P who will perform the work and sign it off.

In that case the work is NOT being performed under the repair station approval, so I agree that an A&P can sign it.

Peter wrote:

How it works in an EASA 145 (without the said TB20 approval) and an EASA66 guy working there, I have an idea but no actual experience.

Assuming it’s an EASA-registered aircraft, then the EASA Part 145 approval can’t be used for the certification but the Part 66 may be able to sign it assuming he/she has the appropriate group or type rating. One issue here relates to the hangar space identified in the Part 145 MOE. If found to be doing work outside the scope of the approval, this could lead to an audit finding. In the past we had to get specific approval to perform work in this manner and segregate a section of the hangar for the ‘un-approved’ aircraft.

Peter wrote:

Say the FAA 145 doesn’t have a TB20 on their list, but there happens to be an A&P working there, and you bring your TB20 in, it will be that A&P who will perform the work and sign it off.

wigglyamp wrote:

In that case the work is NOT being performed under the repair station approval, so I agree that an A&P can sign it.

If an FAA A&P is doing work on an N-registered aircraft in this circumstance it has nothing whatsoever to do with any FAA repair station authorization. The A&P is independently FAA authorized to do the work, and that is regardless of whether the repair station is approved for that type locally or by FAA.

One reason repair stations have approved types and limitations is that they are allowed to use unsupervised non-certificated mechanics to do the work (e.g. foreign licensed or unlicensed mechanics) so the work needs to be regulated more closely. When an FAA A&P is working on an N-registered aircraft, anywhere, that is not the case and those limits (including the requirement for parts traceability) do not apply. He signs off the work in the individual aircraft’s maintenance logbook independently, and that is all the paperwork that’s relevant to FAA maintenance – the business aspects, invoice and money flow are of no concern to FAA.

What you’re describing in relation to maintenance of N-registered aircraft by FAA A&P mechanics is therefore complete nonsense, although I’d have no doubt that such nonsense might be imposed on you by the UK CAA, your local authority, using the repair station treaty limitations as a red herring and wielding the unrelated power they hold over you. European regulators do go to absurd lengths to extend beyond their proper authority and into the lives of people and work they have no right to regulate. It’s a disease, and by my observation creates a population of people which has difficultly understanding the non-arbitrary rule of law. It also creates a class of collaborators in the maintenance business who use artificial constraints to extract more money from unknowing customers. There have been a couple of those posting on EuroGA in the past.

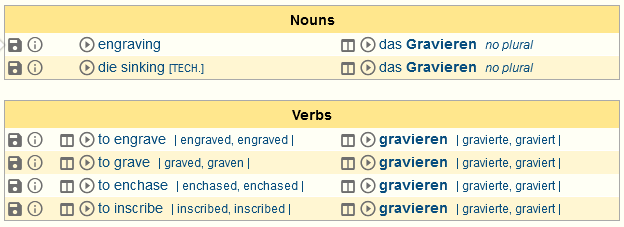

Could the word ‘engrave’ be due to it being written by a non native speaker? E.g. simple translation into German is ‘graviert’, and the infinitive translated back into in English gives the options below from the online dictionary Leo:

It could be the intention was to mark permanently and ‘engrave’ was chosen over ‘inscribe’? Some context on authorship would help.

Any opinions from German speakers?

In French, the only language I can really discuss, ‘graver’ is:

It’s a stretch to interpret it as ‘stamped’

We have a huge number of German pilots here, so somebody must be able to comment

@boscomantico @udoR @snoopy @patrick @terbang perhaps?

I think the intention is to mean “marked” because anything else is ridiculously specific.

The issue is in two parts:

This is an old trick which is used everywhere and in all kinds of situations e.g. a mfg will use a different P/N for the amazon channel to the retail shop channel, so people can’t walk into a shop, google the P/N and find it on amazon for 20% less, and p1ss off the shop.

This is an old trick which is used everywhere and in all kinds of situations e.g. a mfg will use a different P/N for the amazon channel to the retail shop channel, so people can’t walk into a shop, google the P/N and find it on amazon for 20% less, and p1ss off the shop.But we’ve done all this before… I guess EASA got a lot of pushback, under the table of course, from the trade.

The German gravieren/Gravur means removing surface material to create language or a picture on some hard material.

It would mean precisely what is usually not done on many parts.

Cannot logically apply to standard parts, can it ?

Does anybody else get the feeling that there is some national politics here which nobody wants to get into?

Cannot logically apply to standard parts, can it ?

No, because they are usually too small, and anyway engraving (in the literal sense) is rarely used. Methods used include laser marking, ink dot marking, stamping. But most small parts are not marked at all. Larger airframe parts are marked with ink, sometimes with a placard which is stuck on (gas shocks) or riveted on (elevator).

The “problem” is that you are not likely to be buying an elevator from your local DIY shop  so what exactly is this amendment trying to achieve. In most cases, the fact that a part is not counterfeit is blindingly obvious!

so what exactly is this amendment trying to achieve. In most cases, the fact that a part is not counterfeit is blindingly obvious!

As I’ve said before, this amendment was clearly done to sabotage that years-old concession. And it was done as soon as it was to become widely known.

It’s been worded for maximum ambiguity, for maximum benefit to the industry which makes a margin on the supply of parts.

Peter wrote:

The “problem” is that you are not likely to be buying an elevator from your local DIY shop so what exactly is this amendment trying to achieve. In most cases, the fact that a part is not counterfeit is blindingly obvious!

Well it’s not just EASA that are bothered about unapproved parts:

https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_21-29D.pdf

Obviously the FAA does not authorise the use of “illegal” parts, but there is a vast difference between what they allow and what EASA allows.

I think the biggest problem is that GA is a lot “thinner” in Europe and thus people here are much more keen to make money at every opportunity.

This movie from EASA might be useful in understanding the new rules on parts without an EASA Form 1