At the risk of being some sort of conspiracy theorist I am posting a translation of a Mayday from a Robin DR400/140. Fortunately all turned out well and they were able to report in this weeks FFAREX.

Description of the event:

I’m going on an instructional flight with a student to work on diversions. Block departure at 11:20 a.m. UT, takeoff 11:40 a.m. UT. Fuel for approximately 2h30.

The wind is calm, big blue sky, CAVOK, Temperature around 15º, dew point 5-6ºC. Exit DN then EN to transit BLAGNAC up to WH 2000 ft then direct to the town of MONTAUBAN. A little before the town direct to GAILLAC. In GAILLAC, I decide to divert one last time to ALBI. At ALBI, the field is in Auto-Information. During the approach, I ask the student to go around again. The student checks the speed, retracts the flaps 40º then 10º then 0º. He makes a message on the radio to say that he has gone around and another to say that we are going to LASBORDES. I was about to brief him on what to do next (I wanted to refuel at ALBI) when the engine started to shake strongly.

I announced “controls to the right”, the plane was no longer climbing, the speed was dropping. I lower the nose. I reduce the power to see if the vibrations decrease but they don’t. The vibrations seem independent of power variations. I’ll get my glide speed and open to the left. It was very difficult to assess the power that the engine was capable of delivering. Obviously not enough to maintain the climb or the level. During the turn I don’t see a good place to land and I realize that we are high enough and I know that the runway is not far away. The runway is 1600m long. The wind was calm. I continue the turn to land runway 09. The pump was ON, Mixture full RICH, Magnetos BOTH, carburetor heating OFF. At the end of the turn I gave a MAYDAY, although on auto-info, announcing that I decided to land on the 09. At the exit of the turn, I confirmed on the radio that I was going to make the runway. I intercept axis 09 at an angle of approximately 30º, I extend the 40º flaps at the same time as I align myself on the runway. I land 2/3 of the runway, on the axis and stop the plane on the markings of the 27.

Plane stopped, I take the time to breathe, I ask my student how he is. He remained calm. I check all the settings. No lights are on, the fuel gauges are at around 1:30. The engine is still running, the vibrations are still very strong.I pass a message and I clear the track to park under the tower. I see someone in the tower, I ask if they can hear me. The AFIS agent responds. He had just come up when we landed. He thought we were heading backtracking the runway. I inform him of the situation. When we arrived under the tower, he came down to see us and he noticed the vibrations of the engine compartment of the plane from distance.

Comment from the declarant:

I always had in mind that partial engine failures during takeoff often had more serious consequences than when the engine completely shut down. Particularly because of the late decision-making. This allowed me to quickly make a decision.

I was aware of the risks associated with such a shift and its consequences. I was therefore vigilant about maintaining my parameters correctly during the turn.

I did an FI refresher course less than a year ago during which we discussed a lot about events related to security and BEA reports.

I felt particularly on form that day.

I have no idea to this day what could have caused these vibrations and this loss of power.

Educational summary:

After investigation of the fault by our mechanic and the engine manufacturer, the exhaust valve of cylinder 2 was found blocked open in its guide by scale, this blockage having also led to a tearing of the metal on the valve stem.

Each engine cylinder has 2 valves, one for intake and one for exhaust. They move in their guide at the frequency of the engine speed. Blocking in the open or closed position results in a serious situation. Loss of power, significant vibrations etc.

Temperature is the main cause of a stuck valve.

The exhaust valve and its guide are subjected to very high temperatures.

All combustion gases flow around the valve to the exhaust. The large surface area of the valve base absorbs a lot of heat which must be carried out the other end and back to the cylinder head. To facilitate this transfer, Lycoming valves contain sodium. The guide also absorbs heat.

The oil film between the valve and its guide can crystallize under the effect of temperature and transform into scale.

The clearance between the valve stem (straight part of the valve) and its guide (1) being very small, this accumulation of carbon causes the valve stem to block.

Combustion also produces lead and acid deposits which create a corrosive environment.

Corrosion on the valve stem causes an increase in its diameter reducing clearance with the valve guide. Combined with a deposit of carbon, this eventually causes the valve to block.

All these problems are amplified by sudden temperature variations, for example:

- Continuous climb followed by everything reduced for engine failure exercise.

- Engine stopped in parking without stabilizing the engine temperature.

Summary of the action plan:

Corrective actions :

Immobilization of the aircraft and removal of the cylinder for sending to the engine manufacturer.

Preventive actions :

1) Dissemination of a “Flight Safety Flash” requesting the implementation of two new aircraft use practices:

- Arriving at the parking lot with the parking brake applied, wait 60 seconds with an engine speed of 1200 RPM before stopping the engine.

- If possible, during engine failure exercises, stabilize the engine speed at 2200 RPM for 30 seconds before starting the exercise.

2) Checking the other cylinders and their valves.

Just thought it might interest some.

gallois wrote:

risk of being some sort of conspiracy theorist

You’re not @gallois

The 2 big names of horizontally opposed, air-cooled, four, six or eight-cylinder engines, namely Continental and Lycoming, have been producing engines since dozens of years, and this well before the name Rotax was to be found in aircraft engines. Of those thousands and thousands of engines produced, many thousands of them suffered different kind of failures… and still do.

exhaust valve of cylinder 2 was found blocked open in its guide by scale

This is a well known occurrence on Lycoming engines, the more so when the old type of engine guides are installed.

Interestingly enough (could be a cause for the above case too) often due to lack of maintenance… I’ve talked to licenced A&Ps or mechanics not having a clue about the following: there is a mandatory service bulletin for the old guide (SB388C) type with a wobble check every 400 hours (300 hours for helos), and a service instruction for the new guide (SI1485A) with a recommended wobble check every 1000 hours.

I’ve had a couple of occurrences myself, and on a 4 banger in flight, this will lead to an emergency landing. As a pilot, if there’s any sign of what we call “morning sickness” e.g. the engines coughs, or runs irregularly on 3 cylinders (or 5 for a 6 shooter) for 1-2 minutes, then smooths out… don’t go flying!

The valve is starting to stick and the engine is telling you something, better listen…

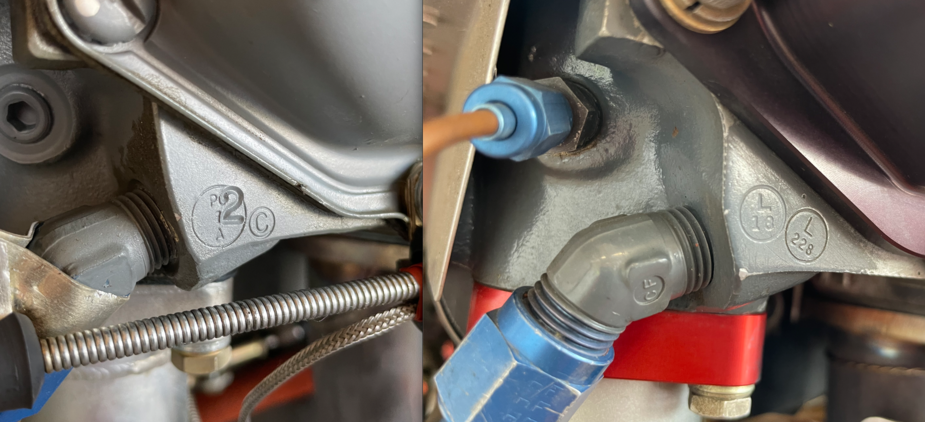

For those interested, the cylinder on the left, with a stamped circled C, denotes the newer type of guide.

I bet dollars to doughnuts that the left exhaust on the Robin was whitish for a couple of days or weeks before the mishap happened. Easy to spot during preflight check.

Ask me how I know

RV14 wrote:

Easy to spot during preflight check.

For most of the pilots: no. Who looks into the exhaust pipe? From below? I do on mine every time (partly because it is very easy), but I did not on the planes I rented in the last months.

I do hope that on a 6-banger it has less influence. However, I hope more that I’ll never experience it.

Yes; stuck valves are an old thing. One has to idle the engine immediately after it starts (and preferably heavily leaned) and check it runs smoothly. That is how you detect “morning sickness” i.e. stuck valve(s).

Lyco and Conti have various issues, though mostly different issues. These tend to be known quantities, with very little new stuff / new issues surfacing since roughly the 1960s. I have zero experience of Rotax but having been reading about this for years I think they have the same number of issues, but different ones  and possibly masked by selective reporting on GA social media.

and possibly masked by selective reporting on GA social media.

Reporting of Rotax issues is probably more selective than Lyco/Conti which everybody slags off all the time even if they own one. This is because a much higher % of Rotaxes are flown by aircraft owners, and owners tend to not slag off their stuff because they want to be able to sell it without the buyer reading about it on some forum  This is actually a huge issue in GA.

This is actually a huge issue in GA.

exhaust on the Robin was whitish

And? Both of my exhaust mufflers of Liese type are whitish, and have been for approaching 2K hours. Rather a good sign, and an indication of my running LOP efforts

My bad, I wasn’t clear enough

The exhaust on the side where the valve wouldn’t close, over time becomes lighter then on the other side

I was specifically referring to carburated lycoming on a Robin as I’m rather familiar with that setup and with that failure. Cyl 2 → left exhaust