Is this really possible?

I have read about it a few times.

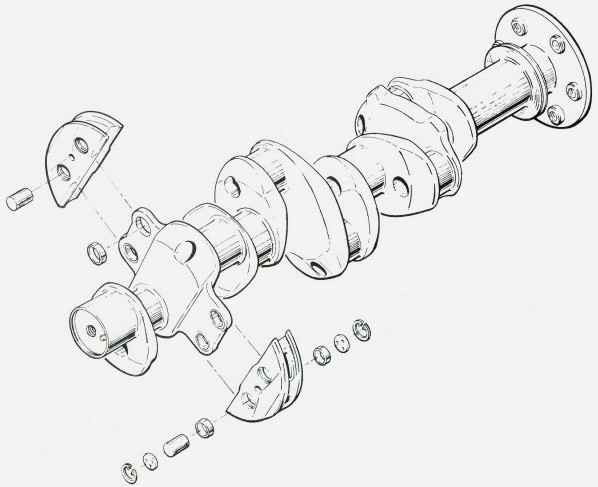

The counterweights are bits of metal attached to the crankshaft, and they swivel (to a small extent) on bearings. They reduce the out of balance forces.

Short of the counterweight bushings seizing up, I can’t see what damage could possibly happen.

It is a short term effect, I believe.

When changing RPM, it takes some time for the counterweights to adjust. Also, if the engine is vibrating, it takes longer than if the transition is smooth.

So we really talk about a few seconds of increased vibration and shaking – more a comfort thing, I’d guess.

Cobalt wrote:

more a comfort thing, I’d guess.

Guessed wrong I guess. AFM says this:

“CAUTION These engines are equipped with a dynamic counter-weight system and must be operated accordingly; avoid high engine speed, low manifold pressure operation. Use a smooth, steady movement of the throttle (avoid rapid opening and closing). If this warning is not heeded, there could be severe damage to the counter-weights, rollers and bushings.”

I’m wondering whether it would be easy or hard to get some evidence. It might only show up over time as the crankshaft/bearings wear out before the end of it’s normal life…?

I have a couple of issues with this stuff.

One is that it cannot possibly be so easy to (in effect) destroy an engine just by opening and closing the throttle too fast.

The other is that anything attached to the crankshaft cannot be aware of whether the crankshaft is being driven by the combustion events or by the propeller – unless you are looking at the very second-order effect of torsional vibration. That’s a really interesting Q. But I can’t see much potential for torsional vibration between the counterbalance attachment point and the prop flange which is really close.

The word counterweight is really a misnomer. They are not counterweights but pendulum absorbers. They are used to counteract torsional twisting of the crankshaft. I’m not sure why Lycoming have them on some engines, it could be due to CR, prop, ignition timing even.

I found this very good article on the torsional absorbers (“counterweight” is the wrong term; those are fixed parts of the crankshaft) but it doesn’t say anything de-tuning.

This one is better and contains this interesting stuff:

Never read that second bit before!

Yes, but does the second bit comes from a service bulletin that is no longer valid…? I couldn’t find it on the Lycoming website?

Rwy20 wrote:

Which AFM are we talking about?

GA8 Airvan (Lycoming IO-540)

Rwy20 wrote:

but what is the rationale behind avoiding low MP & high “speed” (RPM?) ? Do they mean avoid the prop driving the engine

I think that might be related to for example simulated engine failures. Slam the throttle shut, and the engine will still be at high speed, but MP will be very low.