Peter_Mundy wrote:

can you highlite the crack?

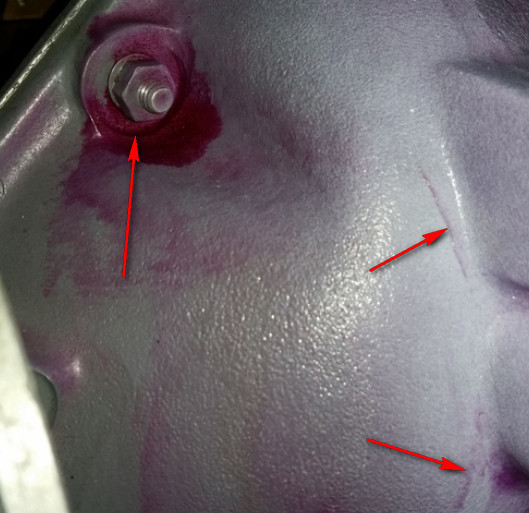

Sure Peter.

There are 2 cracks but you can easily see how they form an arc and are probably joined inside the case.

achimha wrote:

your shop will order one from DIVCO and you might get some WWII crankcase that was patched up 5 times and stamped as “overhaul condition” or “factory new limits”…

Well, “my shop” wouldn’t do such a thing …

Possibly here

Edit: got beaten to it!

Very often it looks like DIVCO is the only source for a crankcase, especially when you don’t want to wait for months.

My impression is that 80% of the overhaul shops in Germany get their crankcases from DIVCO (they have EASA approval). The nature of this whole aviation business is that some people have government entitlement to stamp old stuff as “new”.

I don’t think anybody in Europe does crankcase refurbishment or is there? What other options to DIVCO exist when you’re in need of a crankcase?

The nature of this whole aviation business is that some people have government entitlement to stamp old stuff as “new”.

They pay a heavy price for it which they need to somehow recover

Shipping crankcases to the USA costs relative peanuts – I would estimate €300 max each way by DHL, 2 day service.

Peter wrote:

Shipping crankcases to the USA costs relative peanuts – I would estimate €300 max each way by DHL, 2 day service.

Yep, and I’ll have all the new parts, ie. bearings; rings, gasket set, & prob a new camshaft kit, stuffed in the return ship !

Don’t think there’s a crack upper arrow – just me being too lazy to clean-up all the excess dye …

BTW: One of the reasons I posted this is to point out how important it is to take the time to do a very meticulous inspection of the engine every time the cowl is off.

I’m not so sure that the majority of DIY, weekend-A&Ps out there would have caught this …

This is a known weak spot

For which type of engine?

Lucius wrote:

For which type of engine?

All Lycoming 360s. The engine here is an angle valve, 200Hp, IO-360A1 but just 3 or 4 months earlier I inspected an parallel valve, 180Hp O-360 that had a crack in exactly the same place.