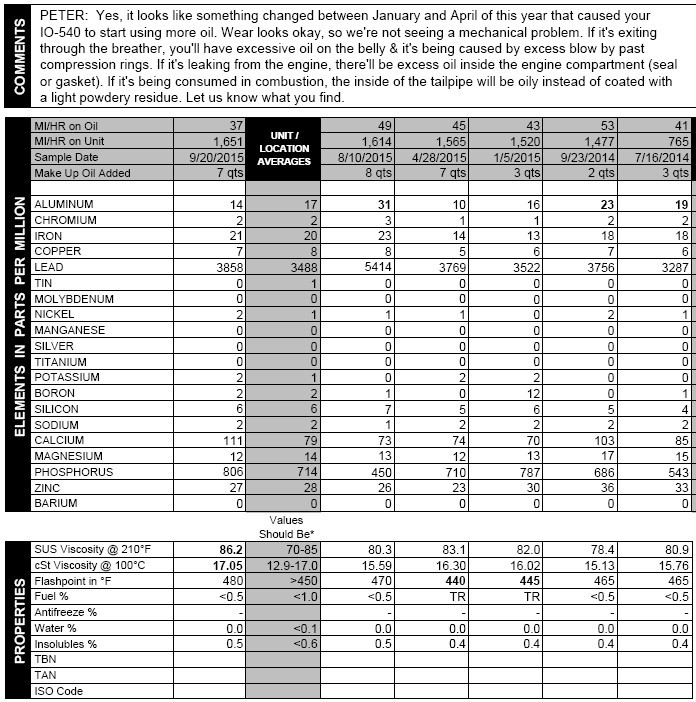

Oil analysis for the sample taken right after the flight Bastia-Shoreham, almost 3 weeks ago, has just come in. Bloody airmail… I thought it got lost. This has happened a few times and I started taking 2 samples, but this time I forgot. That was the flight which showed the high oil consumption. Anyway, even though this is now rather historical, it is interesting:

Viscosity is up, and phosphorus (exhaust products AFAIK) are up. But very little in % terms. I would easily put this down to there being only about 5 qts in the engine when it was drained out. The most relevant stuff is all good. The aluminium has come back down again… Calcium is a tracer added to Camguard.

As regards the Q as to what happened early in 2015 – I had been running the engine with a lower oil level than historically. Around 6-7 rather than 8-9. Several people told me that’s not a good idea; this is one of them:

As I said, the oil burn is back to normal now, after some good thrashing.

Once again, the oil analysis has no value whatsoever, as witnessed by the comments in the header !

oil analysis has no value whatsoever

I don’t agree, unless you want to make the same argument as UK NHS GPs make against getting one’s PSA tested.

The data does eliminate various possibilities e.g. a bearing(s) getting insufficient lubrication. You won’t see anything in the oil filter, and even less in the strainer, until chunks of metal start breaking off. In the same way, a PSA of say 0.5 or less gives you a chance of 1/6000 of ever developing PC (ref: Mark Emberton).

My oil usage has improved since the recent long trips but at about 2.5 to 3 hours per qt which while stable is a significant rise from say 6 months ago so I am getting it looked at on Wednesday. Many thanks to those people who recommended the firm in Thurrock. I will report on any findings.

Peter wrote:

I don’t agree, unless you want to make the same argument as UK NHS GPs make against getting one’s PSA tested..

I’m not so sure that your analogy with PSA screening is all that relevant.

I propose another Medical example that, IMHO, suffers from the same weakness as oil analysis.

Consider FOBT for Colorectal Cancer screening.

Just like Oil Analysis, the test produces a very large % of false positives and in itself does not provide any reliable “actionable” information.

The scenario is the patient gets a false “positive” FOBT result so he gets a colonoscopy, which is the only reliable way to detect. The problem is the patient gets a false “negative” result and then foregoes the colonscopy, which is what he should be doing in the first place.

So the analogy is check your oil filter NO MATTER WHAT THE OA RESULTS ARE !

.

The data does eliminate various possibilities e.g. a bearing(s) getting insufficient lubrication. .

Does it for sure ? I think not. Extremely plausible to have a bearing coming apart without a significant change in the analysis results.

.

You won’t see anything in the oil filter, and even less in the strainer, until chunks of metal start breaking off. .

True, but you will NEVER tear your engine apart JUST because some such figure is out of lines in your OA results …

.

My oil usage has improved since the recent long trips but at about 2.5 to 3 hours per qt which while stable is a significant rise from say 6 months ago so I am getting it looked at on Wednesday. Many thanks to those people who recommended the firm in Thurrock. I will report on any findings.

Please do !

So the analogy is check your oil filter NO MATTER WHAT THE OA RESULTS ARE !

I don’t think anybody would or has suggested otherwise.

but you will NEVER tear your engine apart JUST because some such figure is out of lines in your OA results

If I saw say tin going from 1ppm to 10ppm then I would not fly over significant distances of water (main bearing lubrication issue). Just like right now in fact, consuming 1qt in 3hrs.

Or I would send the engine for an OH even though it has just 1800hrs on it.

There are different degrees in attitude to risk. What you are basically saying is that all the time the oil filter has no bits of metal in it, the engine is fine. Most maintenance companies would agree, but most engineers will never fly in any GA plane

Just like Oil Analysis, the test produces a very large % of false positives

I don’t think OA produces false positives if you are smart about it. It gives you a picture of which bits of the engine are wearing. You look for trends, and eventually you might act on large excursions even if not backed up by metal in the oil filter. I know most people don’t do OA but that is not a good argument because a fair number of people do get engine failures due to a loss of bearing lubrication and I would say these would have been detectable in OA.

A separate issue which I have seen is people refusing to do OA, and probably refusing to cut open the oil filter, in case they find something they don’t like. I’d say that’s really dumb. But the same happens in human health too… the problem is that with human health, a lot of stuff has no effective treatment (a great deal of medicine is really still 19th century stuff, and very few drugs actually work, or work without ridiculous side effects) so there is a good argument for not testing for a lot of stuff. Whereas with an engine, the worst case is that you have to pay $30k. But you will have to pay $30k anyway, at some later stage. And anybody playing in piston GA as an owner must be capable of writing a cheque for $30k at any time…

Just been to General Aero Services, Thurrock, as recommended by a few people here.

Really nice people – very very helpful. The most helpful firm I have been to, ever. And smart, too.

Compressions are ~75/80 on all cylinders, so lower than in January (when some were up to 78/80) but still fine.

Borescope showed nothing except a little bit of glazing on #6. That correlated with the spark plug pics posted earlier. I didn’t remove the bottom plugs and the top plugs all looked equally perfect. All piston tops looked normal and all the same.

All valves looked good.

There was a small leak at the top of the breather tube, at the start of the flexible section, but that may be oil which comes out of the breather anyway. It was tightened up. I will replace that flexible tube.

The oil loss on the last flight (not today’s) was 1/4 qt per hour. If that is a trend it’s pretty good, but I doubt it because much depends on how exactly the plane is parked. My tests show that if you want the dipstick level to stabilise within 1-2mm you must wait 2hrs after shutdown and not move the aircraft.

So, based on that, what are you going to do ?

What would you do?

Peter wrote:

What would you do?

Keep flying and continue to monitor the situation.

If or when your comfort level becomes unbearable (think tightening sphincter  ) , then go pull the jug(s) that’s wet.

) , then go pull the jug(s) that’s wet.

BTW: A couple of psi difference from one test to another is really insignificant. There are just too many variables to derive anything significant from small differences in readings. One example is how aggressively the mechanic looks for the best reading possible. Rocking the prop and finding just the right spot where the compression diff is highest can be the difference between 65 and 75 psi on a reading.

BTW: My Columbia burns 1qt/ 4-5 hours since I’ve owned it, going on 75 hours now, and since it’s very stable at that burn rate and there are no leaks whatsoever, I’m not motivated to pull any jugs.