Is there a practical replacement for the alodining/chromate conversion treatment available? I am in the process of installing a new VHF COM antenna (RAMI AV-17), and the general advice seems to be to scuff the paint away from the contact patch, corrosion-protect the aluminium e.g. with the stick-on CR 1132 applicator, and mount the antenna without the gasket but with a thin bead of RTV silicone along the edge onto the skin in order to achieve a good ground plane connection.

Unfortunately, it seems almost impossible to buy the CR 1132 applicator due to the classification as hazardous substance, so I wonder if I could leave the scuffed skin untreated and rely on the RTV sealant to protect from moisture and subsequent corrosion, or rely on the mounting studs to provide a VHF ground via scuffed skin on the inside of the skin.

The transponder antenna (RAMI AV-74) interestingly has no metal contact surface and seems to rely either on grounding via the contact studs or capacitively to the skin.

Try Bonderite M-CR 871 instead of 1132. It contains less hazardous trivalent chromium rather than hexavalent one, and is available at Aviocom (they have 1132 as well).

Does alodyning actually do anything which a decent primer doesn’t do?

I have done it many times, as advised, but always wondered whether it was of any use.

Thank you very much! Aviocom sits just a few miles up the highway, I’ll contact them. Apart from the slightly less hazardous chrome compound, is there an advantage of the 871 over the 1132 if I can buy either one? As far as I understand it, the hexavalent chromium formulations provide by far superior corrosion protection compared with their nanny-state replacements.

Peter wrote:

Does alodyning actually do anything which a decent primer doesn’t do?

Alodining (i.e. chromate conversion) provides a very thin anti-corrosion layer (and something the primer can bite into) but the metal-to-metal connectivity is basically there. Primer would usually provide a non-conductive layer that would render in my case the antenna ground plane connection less useful (and in that case I would stay with the current paint on metal).

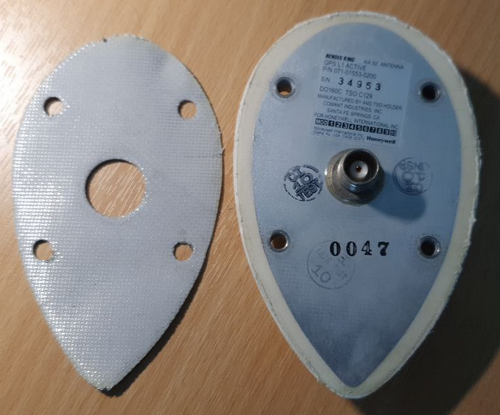

The system I have previously seen is like this

where the antenna has four screws plus a conductive base, and comes with a compressible conductive gasket which is supposed to ensure a good area contact with a metal aircraft roof.

If the four screws make contact with a metal roof that is an additional bonus.

Yes one should not be priming that surface, obviously – that was an irrelevant Q of mine

If you don’t have that gasket you can buy the material in sheet form. How much difference that gasket makes IF the four screws make a good contact is a good Q (at VHF frequencies I doubt it makes much difference – @alioth may know) but check what the antenna looks like under the screw heads. On the one I have here – a Garmin GPS antenna – the screw head would make a good contact because there is bare metal there.

If all else fails, LAS Aero still sell the CR 1132.

Peter wrote:

antenna has four screws plus a conductive base, and comes with a compressible conductive gasket which is supposed to ensure a good area contact with a metal aircraft roof.

Interesting; the installation kit provided with the antenna includes a gasket, but I would characterise it as standard rubber one, definitely not looking similar to your part. I’ll probably install it for now without the provided gasket and run a Hylomar Blue bead as sealant around the edge (there’s a nice groove already milled into the base plate), and protect the metal contact patch using the anti-corrosion metal preparation (thanks Ultranomad and Raiz for providing sources!).

There are “rubber” gaskets which achieve conduction by having metal fibres running across their thickness, if you get what I mean. If you put a meter on two spots on it, it reads no-connection but if you put it across the thickness you get a contact.

The principle is also widely used to connect to LCD displays.

Yours may be one of those.

If it is really not conductive then I would not use it. If stuck, I would lay a length of copper braid under the antenna, in an oval pattern, close to the perimeter of the screws, and that should squash when the screws are tightened.

Sebastian_H wrote:

Apart from the slightly less hazardous chrome compound, is there an advantage of the 871 over the 1132 if I can buy either one? As far as I understand it, the hexavalent chromium formulations provide by far superior corrosion protection compared with their nanny-state replacements.

My educated guess was also that hexavalent chromium would be somewhat better, but Henkel says:

BONDERITE M-CR 1132 AERO is a hexavalent chrome chemical conversion coating and BONDERITE M-CR 871 AERO is a trivalent chrome chemical conversion coating. BONDERITE M-CR 1132 AERO leaves an apparent yellow gold coating after application and BONDERITE M-CR 871 AERO leaves a clear iridescent coating after application. Performance of both coatings meets the same corrosion protection and paint adhesion requirements per MIL-DTL-81706B.

Never tried Hylomar Blue. Around here, black RTV silicone is used on most antennas.