Does anyone have a rule of thumb for calculating gravity-fed fuel flow rate for a given pipe diameter?

One can of course find various engineering sources on the web which will give you the formulae, but these don’t seem to account for the ever-reducing head as the tank empties.

The context is a wing tank in a PA17 draining (in flight) into the main tank. The idea is to achieve a flow of around 25 litres per hour, the cruise consumption being approximately 18 litres per hour. This would allow one to open the valve once the main tank is down to 50%, allowing the transfer to complete in something under 2 hours without a risk of overflowing the main tank, but avoiding the prospect of fuel being consumed faster than it can be supplied.

My gut instinct says that draining such a tank over such a long period of time would require a really quite narrow outlet/pipe?

It does not seem desirable to end up with a fast-flow system where the valve needs to be turned on and off repeatedly to avoid overflowing the main. Preferable is a system where for a long leg one can burn the main tank down to 50%, then open the transfer valve and forget it.

Relying on the tubing to limit your flow rate is unsafe – there are too many influencing factors, even the condition of tube surface will play an important role in case of tubes as thin as the ones you need. It’s better to overdimension the tubing and install a simple mechanical flow meter and a valve to adjust the flow.

Ultranomad wrote:

It’s better to overdimension the tubing and install a simple mechanical flow meter and a valve to adjust the flow.

That is what I thought might be the case. Do we just use standard 1/4 inch pipe (well in excess of the required flow) and fit a device inline to limit the flow to a given value? It would be even better if this valve was adjustable in flight.

The unregulated systems I have seen are fast flow, much faster than I’d want.

Graham wrote:

One can of course find various engineering sources on the web which will give you the formulae, but these don’t seem to account for the ever-reducing head as the tank empties.

Most of the head is still there when the upper tank is almost empty. Head is only dependent on the vertical height difference to the lower tank, not on the area or level in the upper reservoir.

Ultranomad wrote:

It’s better to overdimension the tubing and install a simple mechanical flow meter and a valve to adjust the flow.

I think that’s right.

A regulating valve is in principle different than a shutoff valve, but if you’re careful you could likely use a simple ball valve to regulate flow well enough and this would allow you to resume max flow quickly if needed.

I have an 11.5usg wing tank gravity fed into a 12usg nose tank. If you time it wrong yes you can overfill the nose tank. If I’m over water as it’s a float equipped, I’ll wait till the nose tank gauge is almost stopped moving, then open the valve. It will flow right away helped by a side slip and release to help it. I would be more conservative if not over a landing site.

If you over fill the tank, you get a splash on the windscreen and you know you have to land inside 1hr 40mins with my C90.

I can certainly measure the OD of the stock ally pipe.

Silvaire wrote:

Head is only dependent on the vertical height difference to the lower tank

The vertical height from the outlet of the upper tank to the inlet into the lower?

I assumed the level in the upper tank mattered a good deal, since when I fill my watering can from my water butts the flow rate is much higher from a full butt than an almost-empty one?

WilliamF wrote:

I can certainly measure the OD of the stock ally pipe.

Cheers – I’ll send you a PM to ask a few more questions about the setup. Looking for a known-good design to use as a baseline.

Graham wrote:

I assumed the level in the upper tank mattered a good deal, since when I fill my watering can from my water butts the flow rate is much higher from a full butt than an almost-empty one?

I’m not sure I understand the geometry here, but it could be because in the case of a watering can the height of the tank itself is a significant fraction of the total head height, I’d guess 50%.

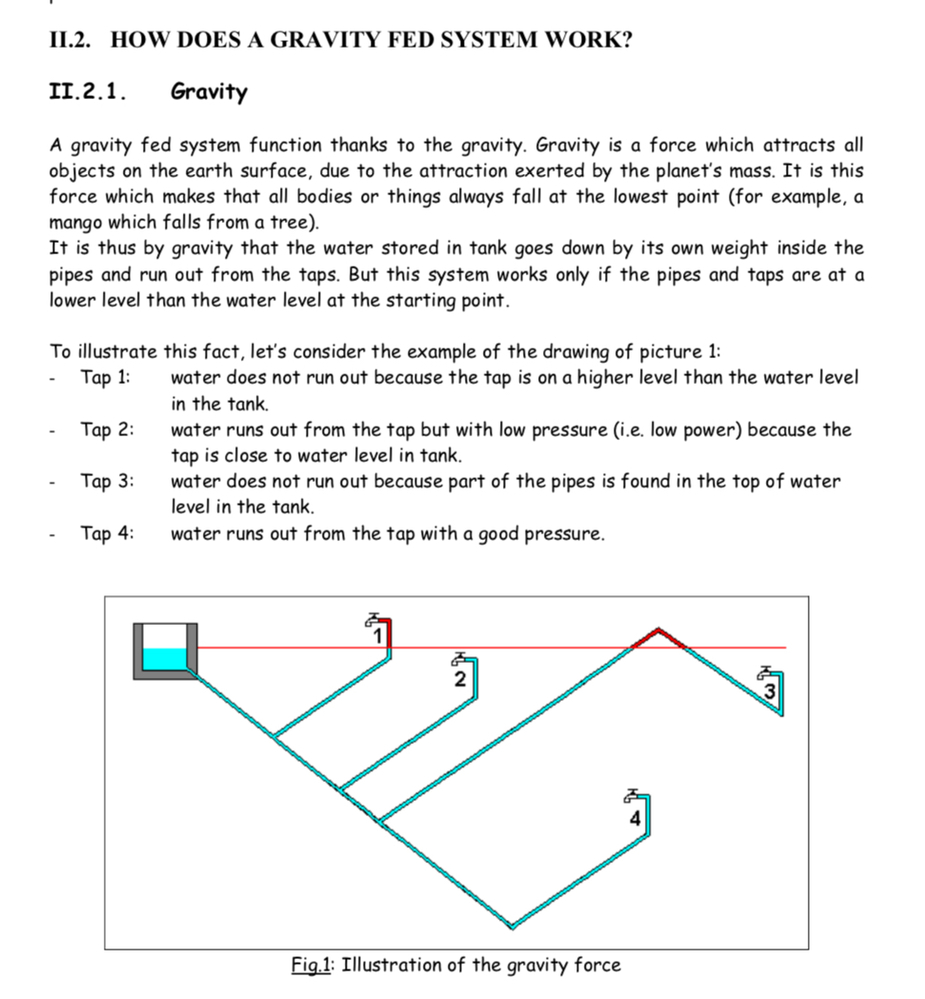

The diagram below is from here Note that the level in the tank is not the critical factor in the flow from the different outlets in the diagram. The red line only moves up and down a little in relation to the total vertical distance.

Silvaire wrote:

That’s because the height of the tank itself is in this case a significant fraction of the total head height, I’d guess 50%.

With you, cheers.