Well done Lenthamen! It’s great reading your story. Very encouraging.

I think there may have been two factors in your happy outcome:

Firstly and absolutely most importantly your clear-thinking pilot head. Well done you. Fantastic. It’s such a skill to keep a cool head in such circumstances and what a good landing. Brilliant.

Secondly the fact that you were flying in Holland which doesn’t seem to have any sort of hill or valley in the whole country, so every surface is flat or nearly flat. I exaggerate of course, but when I have driven and flown in northern France, Belgium, Holland and northern Germany, I have been amazed by how flat the terrain is. That’s a big advantage when one has an engine failure. It doesn’t detract from your pilot skill of course, but it did help to give you more of a chance to show off with your engine-out landing :D

As for flying single engined planes at night, my current instructor is an ex-commercial pilot who refuses to train pilots for the Night Rating in a single engined plane. He joking tells such pilots about the advised engine out procedure at night : descend at best glide to 50 ft and then turn on the landing light. If you don’t like what you see, turn it off again.

Happy flying!

Howard

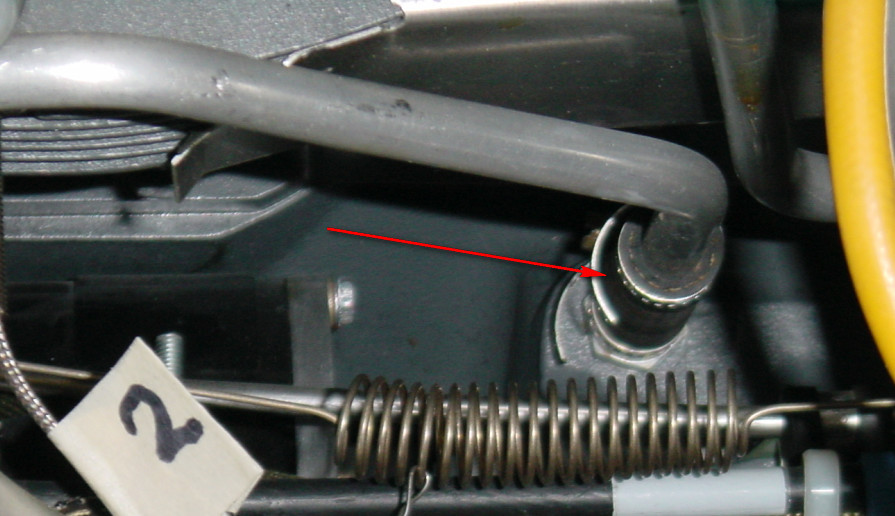

Another Lycoming induction flaw is the rubber hoses that are attached by ordinary hose clamps which tend to get loose. Checking them is part of the 50h check. Mine need regular tightening and over time, the clamp works its way through the rubber hose which needs replacement. If you lose one of them, you’ll park in the same field as Len.

If you mean the hoses feeding oil to the rocker covers

they are fibre reinforced rubber and easily inspected on the 25/50hr check. They usually do need a few tighten-ups when new and then they tend to be OK for years. If somebody tightens the jubilee clip until there is no hose left underneath, he needs a new pair of reading glasses!

descend at best glide to 50 ft

That will only work if the ground is at sea level e.g. around Lydd, or Bangladesh

Peter wrote:

If you mean the hoses feeding oil to the rocker covers

No, those hoses (orange rubber). Major source of induction leaks.

Very strange. These are really thick on mine:

Not sure how a leak in one of these would stop the engine, either.

Nobody said an induction leak would stop the engine but it would severely degrade performance and if the pilot’s instinct is to go full rich, the engine might barely produce power. On a carbureted engine that is, a fuel injected engine would be affected less.

It’s the #1 source of induction leaks, on the Lycoming 50h check list but often forgotten. I check mine every 25h (at oil change). Vibration eventually gets everything loose.

The tubes (post #95) from the rockers are drain tubes, not oil feed tubes to the rockers – ie the oil is draining back from the rocker area to the sump trhough those pipes and rubber tubes.

For sure, the induction hose clamps should be checked regularly to ensure they haven’t backed off but I have never seen a serviceable clamp actually come loose if it was checked at a previous 50 Hour Check.

The most common induction leak is a failed induction gasket where the induction tube is bolted to the cylinder head. Gaskets and tubes split here (thin gaskets and thin walled tube).

The way to find an induction leak in a fuel-injected engine is to do two Gami-spread flight tests, one at say 3000 ft and one at 6000ft. If there is any difference in pattern (which cylinder peaks first) it will point to the leak in the induction system. It can sometimes be found on the opposite side of the engine (balancing tube). The Continental engines have a similar rubber tubing setup that is prone to leaks.

Once you set up your engine to properly run lean of peak, these items must be dealt with.

lenthamen wrote:

This morning the aircraft has been recovered from the field. I got a call that they found the cause:

A gasket came loose and got into the air intake.

My understanding is that some piece of gasket came loose on the inlet side of the carburetor. A Maule crashed shortly after take-off from our field some years ago and it was due to a bit of gasket from the carburetor heat side that caused the blockage. The aircraft was nearly new and was very badly damaged, but the pilot and his wife were unhurt, but broke a bottle of Armagnac.

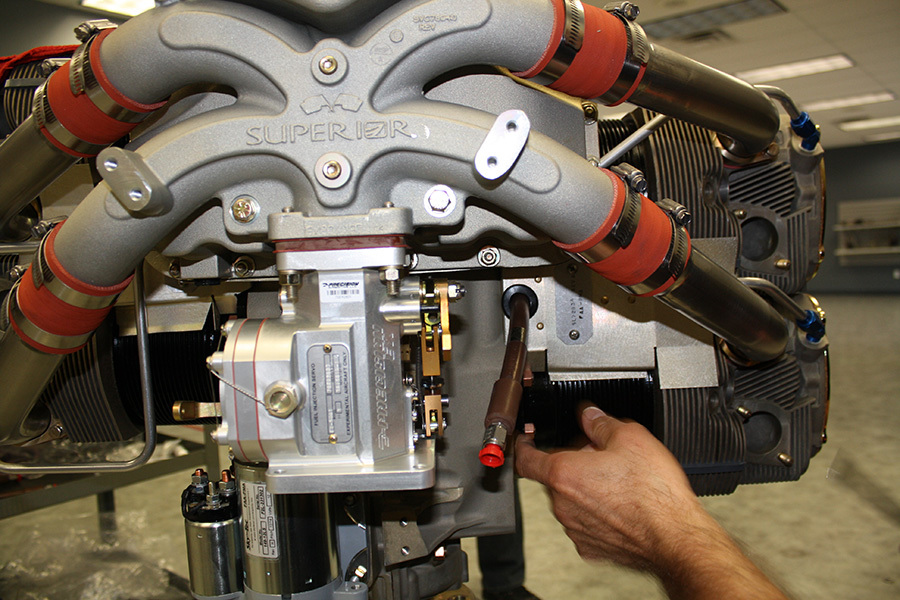

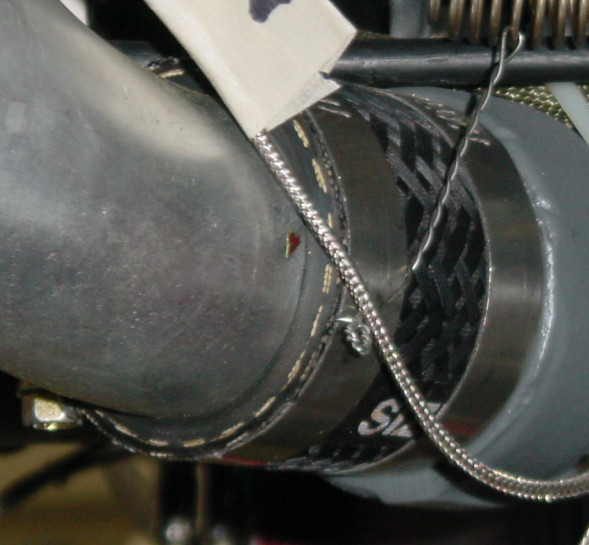

You can see on this photo that two SCAT tubes connect to the carburetor body, one from the carburetor heat and the other from the NACA air intake. A foreign body in either of these circuits could lead to big trouble.

Simon

Is that a metal tea filter at the hot air inlet? I use something similar since I had a mouse in my airbox…

I am sure it could be used as a tea strainer, but it came with my kit and is designed to keep debris out.

Not my plane, but at the same airfield.

Simon