I have a Piper Seneca 3 with Continental TSIO 360 engines with the Turboplus intercooler STC.

I have a JPI EDM790 engine monitor installed.

Latest oil analysis told me I had fuel in oil. Latest oil change, the mechanic informed me the oil was « dead », not « oily » anymore after 30hrs of service.

Winterisation plates installed, blocking 1/3rd of the oil cooler airflow.

I notice that the engine oil is running cold:

2400RPM, 30inch MAP, LOP

LH engine:

Total EGT 1570

Hottest CHT 321

FF 9,7 GPH

oil temp 141F (normal: 160-180)

RH engine:

Total EGT 1520

Hottest CHT 313

FF9,7

Oil temp 148F

OAT was about -5c at FL100, cowl flaps closed

Is this too cold?

Shall I block 1/3rd of airflow oil cooler extra?

Is LOP too cold for my engines (with intercoolers)?

Am I not burning / cooking water, fuel, etc out of the oil by running it too cold?

What are fables, fiction, truth?

Thanks

Niner_Mike wrote:

What are fables, fiction, truth?

Well, as in most questions related to engine problems, you will get a lot of the first 2

Niner_Mike wrote:

Is this too cold?

It is on the cold side. A higher oil temperature will help in burning off any humidity that build up in the crankcase after the last flight.

Niner_Mike wrote:

Shall I block 1/3rd of airflow oil cooler extra?

I would at least block 1/2 of the area, go for a flight, more if needed.

Niner_Mike wrote:

Is LOP too cold for my engines (with intercoolers)?

Yes, especially when your oil T is low as well. The CHTs could be higher, but you should reach higher ones with bigger winterisation plates as well.

Niner_Mike wrote:

Am I not burning / cooking water, fuel, etc out of the oil by running it too cold?

No, it shouldn’t be related. Here is what Lycoming say about fuel in oil:

Gasoline contamination of the oil can result from blow-by from the combustion chamber caused by poor combustion, bad timing, improper fuel mixture, worn rings and the like.

A couple of infos are missing for a better analysis, how many hours on those engines (specifically the cylinders), how were your last compressions, any borescope inspection performed lately (broken rings?), and do you have the oil analysed, results?

Thanks Dan.

1700hrs on the engines on 1800 TBO

Last compressions all above 60, mostly around 70.

No borescope performed

Oil analysis points out the high fuel content of the oil

Is the low oil temp, and fuel in oil, in both engines?

Yes in both engines, so it is probably related to what I do or don’t do.

I would check that the oil temp probes are correctly displayed.

BTW it is no use checking them at room (hangar) temp because the nature of thermocouple probes is that they return zero voltage when the hot end is the same temp as the cold end (the connector on the back of the instrument). So pull out one of the oil temp probes and stick it in some hot water. The instrument could be duff.

The fuel in oil, it’s been suggested, can be caused by priming and then not starting the engine for some tens of seconds or longer. All that fuel will just go right past the piston rings.

On a peripheral topic, with compressions that low, I would deffo borescope the valves.

Peter is correct about checking the calibration of the temp probes, I use a baked bean can about half full of oil and heat it with a heat gun. This enables the temperature that the probe is encountering to be stable enough for accurate measurements to be carried out.

I also struggle to get my oil temps up (Lycoming IO-360, RV-8), even with a fully blocked oil cooler, but I don’t have fuel in the oil. I do use an engine dehydrator. Fly about once a week for an hour or so, with the occasional longer trip. UL91 mostly. I lean as much as I can get away with. What kind of oil are you running? I’m using Total Aero DM 15w50.

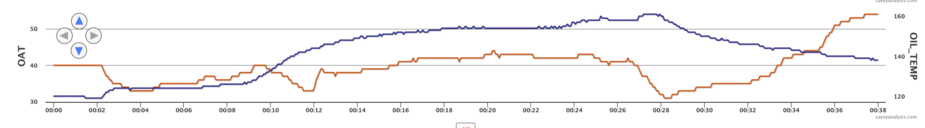

A recent flight:

Yes, my OAT is influenced by engine heat, and will be moved.

Niner_Mike wrote:

1700hrs on the engines on 1800 TBO

Last compressions all above 60, mostly around 70.

Frankly I don’t see much of a problem with your engines, they are just ageing

Running a bit on the cool side, which in cold Ts is not avoidable, unless having a full winterisation kit, i.e. also blocking part of the cowling air inlets. The indicated CHTs might be off by some, so you might, as indicated by others, check their accuracy. Might be a moot point since the indications are similar on both sides.

Fuel in oil is indicative of over-priming, probably on multiple short flights, and also linked to the “low” compressions, e.g. blow by.

The oil being shot after 30h is also a sign of blow by, mostly tired rings and cylinder walls…

Keep monitoring the trends in iron and aluminum contents, the oil consumption, and the compressions. Of course, having the engine borescoped could give confirming clues to the above, and even prevent future problems by inspecting items such as valves, piston crown, cylinder cracks, etc.