I’ve often wondered why these aren’t used on present-day aircraft engines.

Presumably they cannot carry anywhere near as much of a load as plain bearings, have a long life with pressure lubrication anyway, and withstand metal particle contamination which would destroy a ball bearing rapidly.

Were they used historically? In WW2 a lot of effort supposedly went into destroying ball bearing factories…

I think it’s just a function of the type of load found in the engine, there are very few ball races found in car and motorcycle engines and most of these are used to control end float. A lot of two-stroke engines had both crank and big end needle rollers but this was a function of the type of lubrication system ( or lack of one) and a relatively light load.

Gas turbines use ball and roller bearings almost exclusively but these don’t have the high radial loads of a piston engine.

On a historic note, Ball bearings played such an important part to the British war effort that BOAC had a regular cargo route to Stockholm that required flight over German held territory to enable access to the high quality Swedish ball bearing industry. The choice of equipment for this task was the DH mosquito.

Plain bearings depend on reliable pressurized oil flow. Before oil pumps and oil filters were figured out completely, ball bearings were used more on four strokes because they can run with sporadic, low pressure oil supply. The introduction of replaceable multi-metal bearing shells also were a factor – at one time you had to pour plain bearings in place and bore them to size, and the resulting load capacity was relatively low. Assuming those factors are resolved, plain bearings have the advantages of being inexpensive, damage (FOD) tolerant, shock tolerant (no dented races) and easier to assemble. This happened by roughly the 1940s for most (horizontally opposed) aircraft engines although the Rotax 912 uses rolling element con-rod big ends and a multi-piece pressed together crankshaft, making the assembly a replacement item. I think Rotax was still mostly a two-stroke company in the 80s and they used what they knew.

Ball bearings played such an important part to the British war

This is what I wondered about. Does the Merlin engine use them? Did the German aircraft engines use them? (the Dambuster raids were apparently largely for this reason, AIUI).

Obviously gyroscopic instruments use them…

Pressure lubed plain bearings are really amazing. Crankshafts in Lyco engines can make 10,000hrs (say, five engine overhaul periods) and each time you replace the plain bearing shells and maybe sometimes grind the crankshaft a bit.

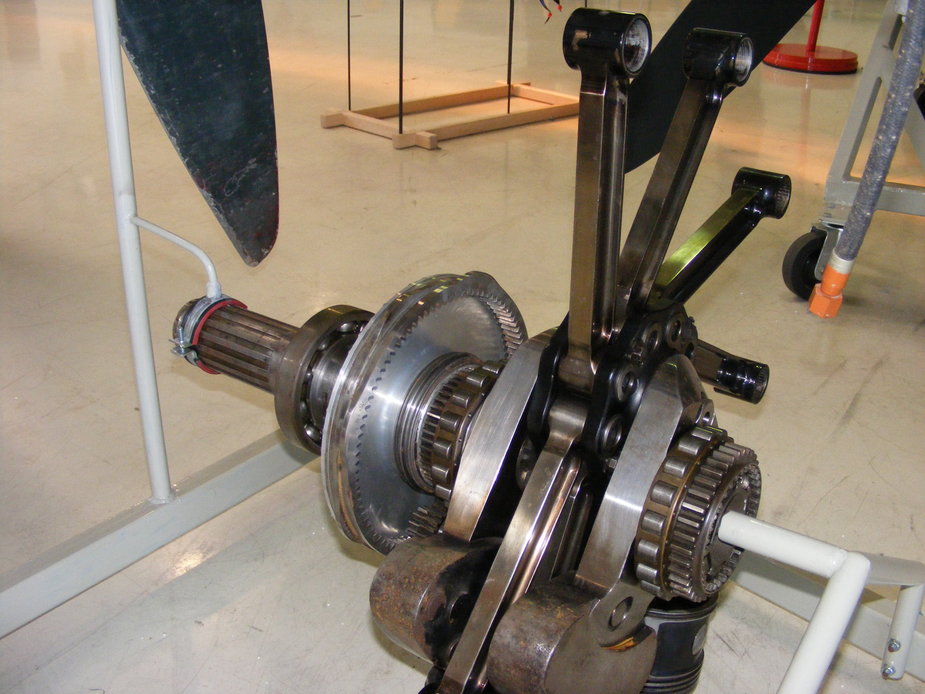

Radial engines often used a mixture of plain and rolling element bearings. Plain bearings work out well for the con rods because the crankshaft can be one-piece. I think the last large radials were done that way. This one has a built up crankshaft and is apparently in an Austrian museum.

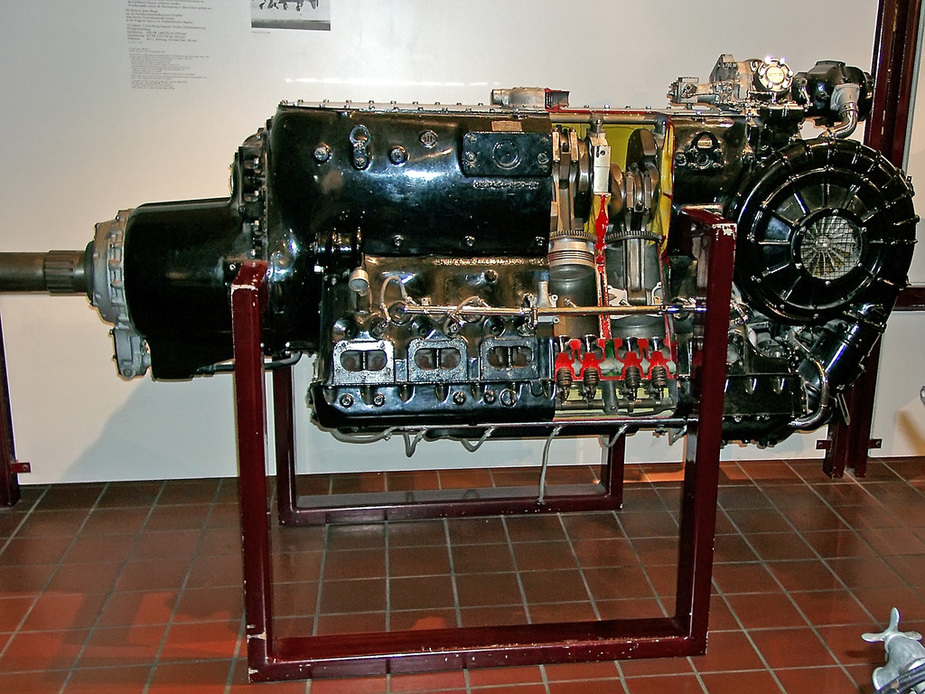

The Daimler Benz V configured engine appears to use plain bearings on the crankshaft, although it is possible to use split con-rods with a rolling element bearing.

I’ve just been reading a great book on WW2 aircraft engines.

UK engines used plain bearings, while German engines used ball bearings because they could not get the special metals which are needed for plain bearings.

What’s the book, Peter?

Many of the “important” bearings in GA piston engines are by design necessity, split. Ball bearings are not dependable when the balls run over a split, plain bearings work fine. It’s amazing how long a very soft babbit bearing will last, if well lubricated. And, if a babbit bearing begins to wear, it’s a non event in terms of metal contamination. A ball bearing making metal will be catastrophic for the engine in short order. Ball bearings capable of carrying any appreciable load have a much greater “thickness” than plain bearings, which would really fuss design considerations, and the mass of connecting rods. As an extreme example, the German Argus engine of the Feiseler Storch fame, has plain bearings for the connecting rods which act over each other, so there are bearings on the inside and outside of the “inside” connecting rod.

Even the brand new RED A03 diesel engine uses plain bearings on all crankshaft and camshaft applications.

Many years ago, I made a special fixture for my lathe, so I could turn to size new babbit bearings for Gypsy Major engine connecting rods. It was a simple task. Gypsy Majors are not known for excellent lubrication internally. They are well know for lubrication externally!

In a VW beetle engine. Not many ball bearing there  I would think that most auxiliary systems have ball/roller bearings perhaps. Gear boxes for instance that isn’t an integral part of the core engine lubrication system.

I would think that most auxiliary systems have ball/roller bearings perhaps. Gear boxes for instance that isn’t an integral part of the core engine lubrication system.