Usually, when we discuss about a miantenance issue, the following pattern is followed :

- somebody asks for help

- Peter describes how he would do it on his N-reg TB20 (which usually involves ONE mechanic and ONE piece of paperwork)

- Silvaire or AdamFrich make everybody jealous in 1) confirming what Peter said and 2) because they have a friend who knows how to repair that suff and another friend who will make the deal 100% legal, everything will get done next Saturday for a cost of approx 1.5 beer in sunny California (we all have the picture in mind)

- 3 or 4 EU guys say it is impossible because in Europe, one needs a very good shop, excellent contacts with your CAA, in short the Garden of Eden of the pilot/owner

- and some guy, usually @mh or somone else, say it is very easy in Europe to do this stuff, you just need one licensed mechanic and …… (I never remember)

- and the debate goes on…..

I feel EASA maintenance regimes have changed a lot in the last few years, and have become more flexible.

The problem is, most of us have no idea of what it works now.

Go reading the legal texts would take…. about twice forever

Finding clear info on FAA Part 91 maintenance is very easy. I remember one slide of Mike Busch showing the whole process of a repair (ANY repair).

So my point is : does anyone have a summary, a drawing, a flowchart, a cartoon  , anything that explains how a pilot/owner of a <1200kg SEP is supposed to maintain his aircraft airworthy ?

, anything that explains how a pilot/owner of a <1200kg SEP is supposed to maintain his aircraft airworthy ?

Shouldn’t it in theory just be a case of SDMP which complies with MIP plus AD compliance for <1200kg and soon <2700kg?

I get the feeling that if I did present you all with an EASA flow chart it would look like six London tube maps on superimposed on each other, this is however an improvement three or four yours back it would have been sixteen tube maps.

@Jujupilote, if you want to know how to arrange maintenance by someone else, EASA Part-M says the following:

M.A.201(i)

For other than complex motor-powered aircraft not included in point (e) or (h), or used for “limited operations”, the owner is responsible for ensuring that no flight takes place unless the conditions defined in point (a) are met. To that end, the owner shall:

(1) contract the tasks associated with continuing airworthiness to an approved CAMO though a written contract in accordance with Appendix I, which will transfer the responsibility for the accomplishment of these tasks to the contracted CAMO, or;

(2) manage the continuing airworthiness of the aircraft under its own responsibility, without contracting an approved CAMO, or;

(3) manage the continuing airworthiness of the aircraft under its own responsibility and establish a limited contract for the development of the maintenance programme and for processing its approval in accordance with point M.A.302 with:

— an approved CAMO, or

— in the case of ELA2 aircraft, a Part-145 or M.A. Subpart F maintenance organisation.

This limited contract transfers the responsibility for the development and, except in the case where a declaration is issued by the owner in accordance with M.A.302(h), processing the approval of the maintenance programme to the contracted organisation.

AMC M.A.201(i) (AMC = acceptable means of compliance)

The limited contract for the development and, when applicable, processing of the approval of the aircraft maintenance programme should cover the responsibilities related to M.A.302(d), M.A.302(e) and M.A.302(g).

In the case of ELA1 aircraft not involved in commercial operations, the limited contract between the owner and the CAMO/maintenance organisation should cover the following aspects:

— Whether the maintenance programme will be based on the ‘Minimum Inspection Programme’ described in M.A.302(i);

— The obligation for the CAMO/maintenance organisation to develop and propose to the owner a maintenance programme which:

GM M.A.201(i) (GM = guidance materials)

Aircraft maintenance programme

If an owner decides not to make a contract in accordance with M.A.201(i), the owner is fully responsible for the proper accomplishment of the corresponding tasks. As a consequence, it is recommended that the owner properly self-assesses his/her own competence to accomplish them or otherwise seeks the proper expertise.

=========

if you mean maintenance by the pilot-owner personally, it is described in Part-M as follows:

M.A.803 Pilot-owner authorisation

M.A.803(a)

To qualify as a Pilot-owner, the person must:

1. hold a valid pilot licence (or equivalent) issued or validated by a Member State for the aircraft type or class rating; and

2. own the aircraft, either as sole or joint owner; that owner must be:

(i) one of the natural persons on the registration form; or

(ii) a member of a non-profit recreational legal entity, where the legal entity is specified on the registration document as owner or operator, and that member is directly involved in the decision making process of the legal entity and designated by that legal entity to carry out Pilot-owner maintenance.

M.A.803(b)

For any non-complex motor-powered aircraft of 2 730 kg MTOM and below, sailplane, powered sailplane or balloon, that are not used in CAT, or not used in commercial specialised operations or not used in commercial ATO operations, the pilot-owner may issue a certificate of release to service after limited pilot-owner maintenance as specified in Appendix VIII.

M.A.803(c)

The scope of the limited Pilot-owner maintenance shall be specified in the aircraft maintenance programme referred to in point M.A.302.

M.A.803(d)

The certificate of release to service shall be entered in the logbooks and contain basic details of the maintenance carried out, the maintenance data used, the date on which that maintenance was completed and the identity, the signature and pilot licence number of the Pilot-owner issuing such a certificate.

AMC M.A.803

1. Privately operated means the aircraft is operated pursuant to M.A.201(i).

2. A Pilot-owner may only issue a CRS for maintenance he/she has performed.

3. In the case of a jointly-owned aircraft, the maintenance programme should list:

— The names of all Pilot-owners competent and designated to perform Pilot-owner maintenance in accordance with the basic principles described in Appendix VIII of Part-M. An alternative would be the maintenance programme to contain a procedure to ensure how such a list of competent Pilot-owners should be managed separately and kept current.

— The limited maintenance tasks they may perform.

4. An equivalent valid pilot license may be any document attesting a pilot qualification recognised by the Member State. It does not have to be necessarily issued by the competent authority, but it should in any case be issued in accordance with the particular Member State’s system. In such a case, the equivalent certificate or qualification number should be used instead of the pilot’s licence number for the purpose of the M.A.801(b)3 (certificate of release to service).

5. Not holding a valid medical examination does not invalidate the pilot licence (or equivalent) required under M.A.803(a)1 for the purpose of the Pilot-owner authorisation.

Appendix VIII – Limited Pilot Owner Maintenance

In addition to the requirements laid down in Annex I (Part M), the following basic principles are to be complied with before any maintenance task is carried out under the terms of Pilot-owner maintenance:

(a) Competence and responsibility

1. The Pilot-owner is always responsible for any maintenance that he performs.

2. Before carrying out any Pilot-owner maintenance tasks, the Pilot-owner must satisfy himself that he is competent to do the task. It is the responsibility of Pilot-owners to familiarize themselves with the standard maintenance practices for their aircraft and with the aircraft maintenance programme. If the Pilot-owner is not competent for the task to be carried out, the task cannot be released by the Pilot-owner.

3. The Pilot-owner (or his contracted continuing airworthiness management organisation referred to in Subpart G, Section A of this Annex) is responsible for identifying the Pilot-owner tasks according to these basic principles in the maintenance programme and for ensuring that the document is updated in a timely manner.

4. The approval of the maintenance programme has to be carried out in accordance with point M.A.302.

(b) Tasks

The Pilot-owner may carry out simple visual inspections or operations to check for general condition and obvious damage and normal operation of the airframe, engines, systems and components.

Maintenance tasks shall not be carried out by the Pilot-owner when the task:

1. is critical maintenance task;

2. requires the removal of major components or major assembly and/or;

3. is carried out in compliance with an Airworthiness Directive or an Airworthiness Limitation Item, unless specifically allowed in the AD or the ALI and/or;

4. requires the use of special tools, calibrated tools (except torque wrench and crimping tool) and/or;

5. requires the use of test equipments or special testing (e.g. NDT, system tests or operational checks for avionic equipment) and/or;

6. is composed of any unscheduled special inspections (e.g. heavy landing check) and/or;

7. is effecting systems essential for the IFR operations and/or;

8. is listed in Appendix VII or is a component maintenance task in accordance with points M.A.502(a), (b), (c) or (d).

9. is part of the annual or 100h check contained in the Minimum Inspection Programme described in M.A.302(i).

The criteria 1 to 9 listed above can not be overridden by less restrictive instructions issued in accordance with “M.A.302(d) Maintenance Programme”.

Any task described in the aircraft flight manual as preparing the aircraft for flight (Example: assembling the glider wings or pre-flight), is considered to be a pilot task and is not considered a Pilot-owner maintenance task and therefore does not require a Certificate of Release to Service.

(c) Performance of the maintenance Pilot-owner tasks and records

The maintenance data as specified in point M.A.401 must be always available during the conduct of Pilot-owner maintenance and must be complied with. Details of the data referred to in the conduct of Pilot-owner maintenance must be included in the Certificate of Release to Service in accordance with point M.A.803(d).

The Pilot-owner must inform the approved continuing airworthiness management organisation responsible for the continuing airworthiness of the aircraft (if applicable) not later than 30 days after completion of the Pilotowner maintenance task in accordance with point M.A.305(a).

AMC to Appendix VIII “Limited Pilot Owner Maintenance”

1. The lists here below specify items that can be expected to be completed by an owner who holds a current and valid pilot licence for the aircraft type involved and who meets the competence and responsibility requirements of Appendix VIII to Part-M.

2. The list of tasks may not address in a detailed manner the specific needs of the various aircraft categories. In addition, the development of technology and the nature of the operations undertaken by these categories of aircraft cannot be always adequately considered.

3. Therefore, the following lists are considered to be the representative scope of limited Pilot-owner maintenance referred to in M.A.803 and Appendix VIII:

— Part A applies to aeroplanes;

— Part B applies to rotorcraft;

— Part C applies to sailplanes and powered sailplanes;

— Part D applies to balloons and airships.

4. Inspection tasks/checks of any periodicity included in an approved maintenance programme can be carried out providing that the specified tasks are included in the generic lists of Parts A to D of this AMC and remains compliant with Part M Appendix VIII basic principles.

The content of periodic inspections/checks as well as their periodicity is not regulated or standardised in an aviation specification. It is the decision of the manufacturer/Type Certificate Holder (TCH) to recommend a schedule for each specific type of inspection/check.

For an inspection/check with the same periodicity for different TCHs, the content may differ, and in some cases may be critically safety-related and may need the use of special tools or knowledge and thus would not qualify for Pilot-owner maintenance. Therefore, the maintenance carried out by the Pilot-owner cannot be generalised to specific inspections such as 50 Hrs, 100 Hrs or 6 Month periodicity.

The Inspections to be carried out are limited to those areas and tasks listed in this AMC to Appendix VIII; this allows flexibility in the development of the maintenance programme and does not limit the inspection to certain specific periodic inspections. A 50 Hrs/6 Month periodic inspection for a fixed wing aeroplane as well as the one-year inspection on a glider may normally be eligible for Pilot-owner maintenance.

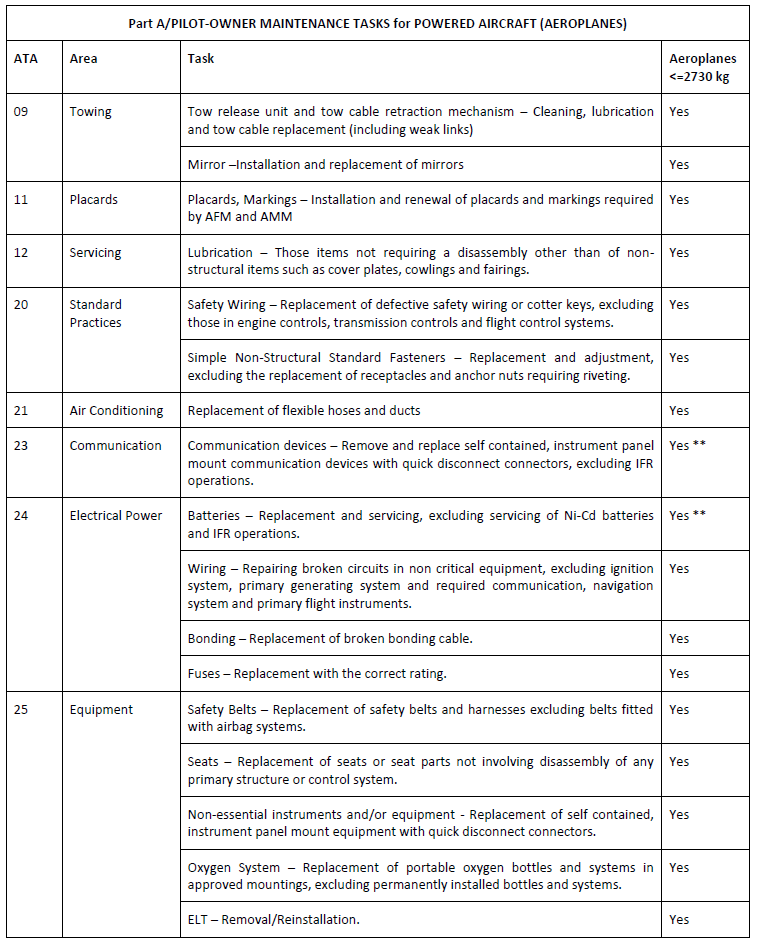

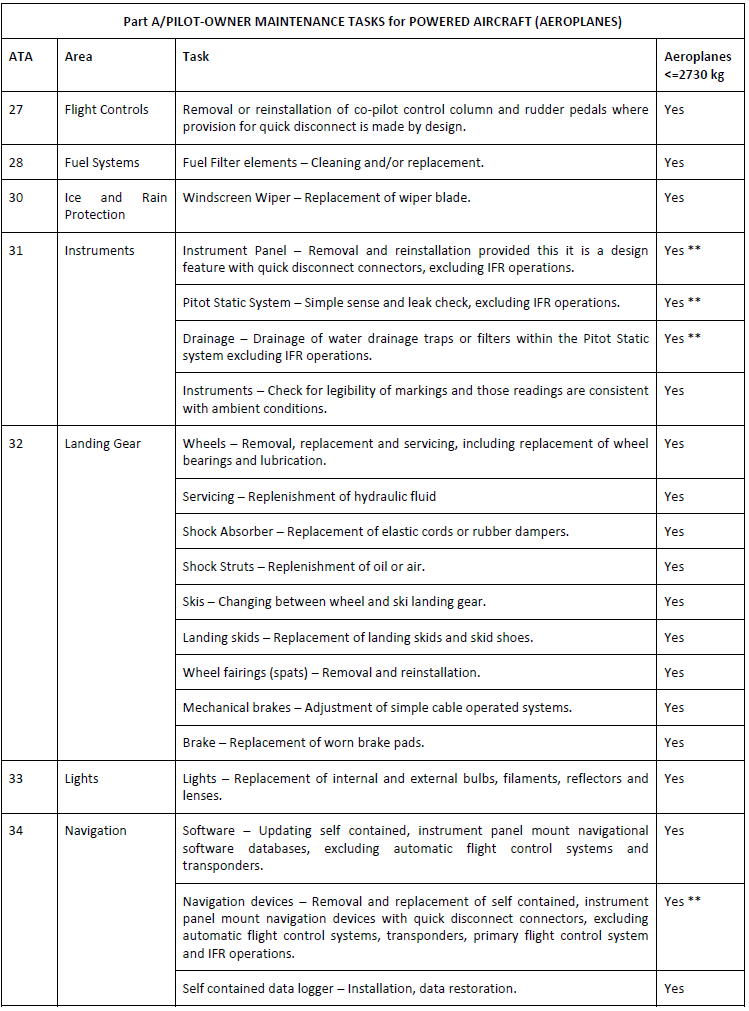

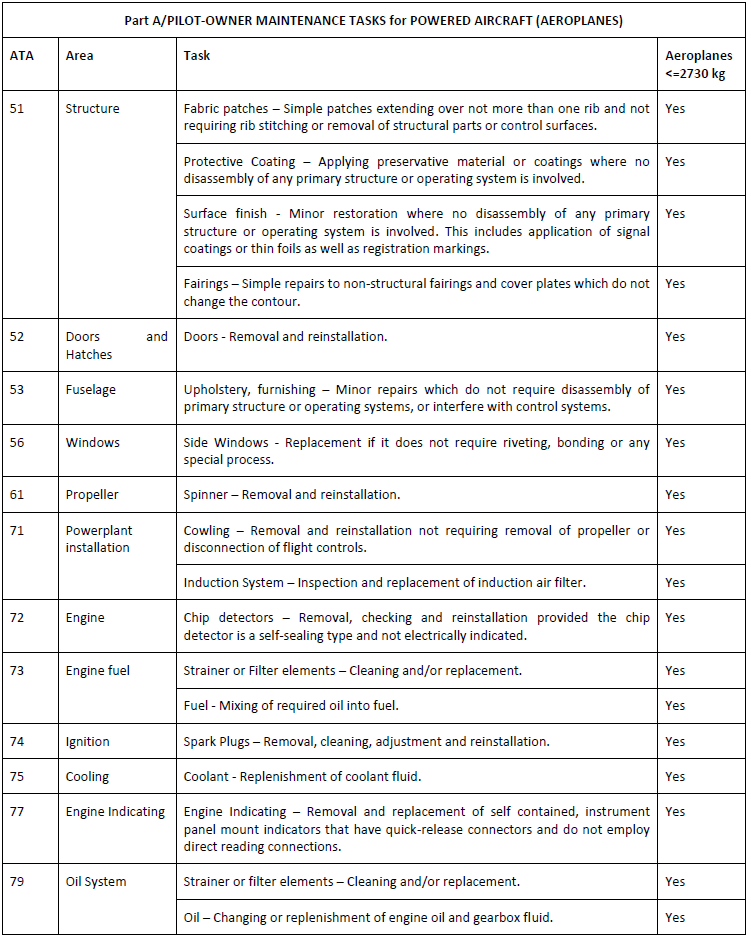

Table: Part A/PILOT-OWNER MAINTENANCE TASKS for POWERED AIRCRAFT (AEROPLANES)

Note: Tasks shown with ** exclude IFR operations following Pilot-owner maintenance. For these aircraft to operate under IFR operations, these tasks should be released by an appropriate licensed engineer.

Thanks a lot Ultranomad, it is a big step forward. What I gather is :

- an owner may write his own maintenance programme or pay a company to do so.

This programme, at the very minimum, must contain an annual/100hrs inspection (cf the Minimum Inspection Programme).

- the owner who wants to write his maintenance programme must compile all his plane’s service manuals, ADs, SBs etc and write what he wants to apply and what not.

- the pilot/owner/co-owner may execute some maintenance tasks, like the 50hrs inspection/oil change. If the aircraft is IFR, his privileges are reduced.

What you have to add to your maintenance programme is not very clear to me : ADs for sure, but then… Sounds like a lot of work but necessary to know your plane well.

an owner may write his own maintenance programme or pay a company to do so

Is this a requirement? For example could the list of maintenance actions in the manufacturer’s MM be followed directly?

I recall a discussion that the MM action list has to be in a specific format, and the Socata MM format, illustrated e.g. here was acceptable – because Socata, being French, knew how to do the layout to be acceptable to the DGAC, and the DGAC later had influence within EASA. I can’t find that thread right now…

The SDMP stuff is a complex topic, due to varying national CAA attitudes. For example in the UK very few people have managed to put a plane on an SDMP – example. Overall in Europe it seems a rarity. I have never met anyone who did it.

the pilot/owner/co-owner may execute some maintenance tasks, like the 50hrs inspection/oil change. If the aircraft is IFR, his privileges are reduced.

Indeed. However he cannot perform anything to do with ADs, so if e.g. you have a plane which is covered by an AD which needs some item to be inspected every 50hrs, that rules out pilot maintenance completely. In practice you get something in between the two extremes.

Currently you have the 1200kg (ELA1) threshold under which a freelance EASA66 can do all tasks. I don’t know whether a CAMO is still required; I believe not.

There are certainly people here who work within the EASA system and know it well. Great post by Ultranomad. The Q I would ask is what degree of knowledge is required of the owner to set this up.

Peter wrote:

I have never met anyone who did it.

I did, and we have met. :-) I did it in order to run the engine past the TBO extension limit the Swedish authority places on approved maintenance programmes. We still used a CAMO to administer the SDMP, though.

Peter wrote:

Is this a requirement? For example could the list of maintenance actions in the manufacturer’s MM be followed directly?

You can take MM for the aircraft + MMs for components + local/regional regulations + ADs + whatever else comes up. Don’t forget that schedules for different items on the maintenance program may slide with respect to each other (different calculation basis), and hiring a CAMO to monitor these schedules seems a good idea to me even when it is not required (for private noncommercial operation it isn’t).

Peter wrote:

The Q I would ask is what degree of knowledge is required of the owner to set this up.

In the first approximation, any engineer worth his salt can do that, though it may not be financially justified in comparison to CAMO.

Peter wrote:

I have never met anyone who did it.

We have self declared MPs on all aircraft (10 aircraft among my friends & family) and it’s not a big deal. 3 hrs to write and after that 0,5hrs/year to maintain (including writing an ARC)

Yes, but you are an expert on the regs, all of Part M, and the implementation in Germany

How did you generate the SDMP, for which aircraft types, and what was in it?