took a couple of pcs of the spar… this one is definitely junk

Hm. Somewhat scary to realize i flew my family in that stuff…

I have flown both the fixed and RG 177’s and have many good things to say about them. That said, as any legacy airplane these days, airframe contrition is everything.The issues with the center spar are very well documented by Cessna, and now, fairly well understood by industry. I haven’t been involved with a 177 spar repair/replacement yet, but I have been involved with several 210’s. One thing to bear in mind is that if the airplane has any structural or aerodynamic mods (a STOL kit being a common example, and for 210’s tip tanks or speed brakes), Cessna will not provide any data for consideration of a corrosion repair exceeding their published numbers. Thus, although I’m generally a STOL kit fan, I would not buy a 177 with a STOL kit installed, in case future Cessna support were needed.

The eddy current inspection will be looking for cracks.

The visual inspection for corrosion will drive a blend-out of corroded areas. There is a limit to the blendout depth. If exceeded, then you need Cessna evaluation. The rejection should come as a result of such evaluation.

In this case, it is likely this partituclar rejection (like all others) was due to excessive depth of the pitting (see the deep blendout in the lower RH side of the pic) . I am not aware of a single cracked 177/210 spar other than the one which drove the SB+AD. Unfortunately on some aircraft this area was neglected in annual inspections over the years due to bad access resulting in a number of aircraft now failing the inspection due to corrosion.

Newly manufactured replacement carrythrough spars for the 210 series have been available from Textron in the past few years. I am unsure about the 177 series.

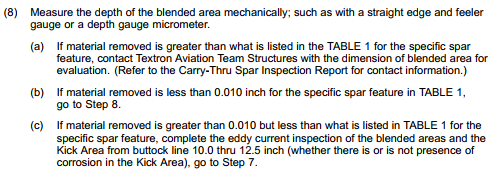

Following is an extract from the 210 SB, but the 177 should be equivalent.

.

Coming back to the OP, if an aircraft has satisfactorily passed this inspection and ensuing corrosion protection, this will not be an area of concern on the relevant airframe.

Affirm, that is the old reject, with corrosion pitting visible on the 1st pic. The 2 areas where the alodine has been removed in the 2nd pic, is the area which is specifically eddy tested, so I’ve been told, though the process itself was outsourced.

Paid a visit to the local maintenance outfit today, and took a couple of pcs of the spar… this one is definitely junk, but slightly too heavy to serve as a paper weight…

Great looking pane indeed, and a pity they didn’t keep these in production. The tecnam p2010 is very similar although quite recent.

I’m unsure about the 150hp 177A model, as I’ve never flown one. The 1974 Cessna 177B we have has a different cowling, 180hp engine and CS prop. The 177 is a real sweet handling aeroplane, with deep chord ailerons and the all-flying stabilator making it totally different in feel than a 172. Ours had a replacement carry-thru spar 20 years ago, and we are doing the AD on the carry-thru next month. They are a great all-rounder, but the doors/fuel selector/flare need a bit of consideration.

I would recommend paying the $35 to join the CFO type group. Here is what they have to say:

Cardinal Facts: Fixed Gear

1968 Fixed Gear

Air intake in cowl under spinner.

Large, trapezoidal engine cooling air inlets.

Landing lights in wing. (two PAR36)

150 horse engine (Lycoming O-320-E2D).

Fixed pitch propeller.

‘Thin’ wing.

No over-voltage switch: thermal circuit breaker in circuit.

Long, pointed wheel pants.

Steps on fuselage.

Narrow panel.

Often converted to 180 HP engine.

Overview: The ’68 was intended as a replacement for the 172, and it was decided that the market wanted a 150 horse engine. A large number were built, and later modified with a slot in the stabilator. After this modification it flew ok, but was never known as a strong performer.

Owners of the ‘68 describe it as an honest, capable airplane, and are quick to point out it’s lighter weight and better efficiency. The thin wing is more efficient than later wings, and many ’68 owners are flying quite happily.

Most Cardinal owners, however, would recommend caution in a ‘68. Don’t plan to fill the seats on a warm day, and take the performance numbers with a grain of salt.

If you are careful this year can provide excellent performance at a bargain price

AFAIK it is a 1 time inspection for the AD, then just regular inspection by general engineers going forward to check there is no further change.

So in theory, just a 1 time cost for Eddy current and deep inspection. Plus the additional paperwork to submit findings to the FAA.

The worst part in some aircraft is removing all the trim and headliner in a manor where it will go back nicely.

The older the fit-out, the worse it gets.