We have just inspected a customer’s LOM Praha M137 engine that suffered a major prop strike at full power as the landing gear collapsed during take-off run. One blade of the prop was bent forward, which is a sure sign of high-power strike, whereas the other one was bent back – that is, the engine stopped within half a turn. Discovering the first problem didn’t even require disassembly: the prop flange got stuck solid on the crankshaft. We broke the standard puller trying to remove it, and a reinforced one didn’t do anything at first. Eventually, however, we managed to coax it off with some 1000 N·m of torque on the puller screw (which is three times the normal torque for the nut holding the flange on the crankshaft):

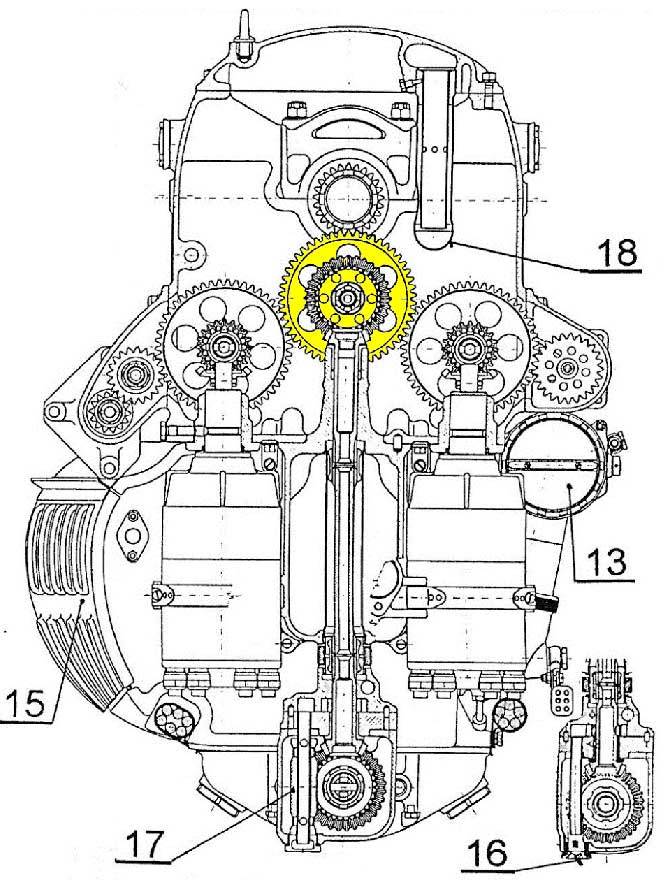

Amazingly, the crankshaft seems OK – I haven’t measured the runout yet, but it showed no signs of catching when rotated by hand in the bearings. The timing gears weren’t so lucky. The crankshaft has a toothed sleeve at the rear end, which drives a straight-cut gear riveted to a bevel gear (shown in yellow), which then drives a vertical shaft going down.

The rivets attaching the two gears were partially sheared:

The gear itself suffered fatally: a crack, a severely chipped tooth at the end ot the crack, and pitting on the next tooth to the right.

Other gears are also pitted, though not so spectacularly…

Damn, that’s some mean force at play.

Thanks for sharing.

It’s hard to tell from the photo but that looks like a cast gear with somehow hollow teeth. What’s the actual situation? The tooth next door to the failure looks badly pitted, incipient fatigue failure that I wouldn’t suppose has anything to do with the prop strike. If it’s as bad as it looks, understanding that photos can ‘lie’, I’d say it’s a good thing the engine was taken apart for other reasons – it looks awful in the photo.

Thanks for posting info on the LOM engine, it’s interested me for some time, before and after reading articles such as this one. The bevel gear and tower shaft arrangement is very ‘old school’, all those gears… It’s not a common engine in my area although one or two people have put them on RVs, which interested me equally at the time.

Amazing; thank you for posting that. One hears of accessory gears getting damaged during a prop strike but it is quite rare.

I agree with Silvaire in that that gear appears hollow – maybe a casting defect leaving a bubble there, so possibly the long crack was pre-existing. One can tell the age of a crack though, so that will be interesting.

The pitting in the other tooth is a classic sign of corrosion, but I would expect to see that in some other teeth too if it was that.

Answering Silvaire’s and Peter’s concerns, the broken tooth certainly wasn’t hollow, the cavity is wedge-shaped and has a surface appearing freshly broken – I’ll see if I can take a better photo. Pitting on the other tooth is also unlikely to be due to corrosion: the engine was recently overhauled and looks quite fresh everywhere except the gears, and then only the higher-stressed ones. We routinely see this kind of pitting on heavily stressed engines (towing, aerobatics) rather than on hangar queens.

Very interesting at last an engine which actually did sustain damage from a prop strike while most others turn out fine. I am not a huge fan of MT wood props for other reasons but in such cases they can for sure protect the engine.

thanks for posting Ultranomad, very informative!

Never worked on a LOM, and learning how a very sturdy motor takes the damage. There are huge forces in motion…

Ultranomad wrote:

Pitting on the other tooth is also unlikely to be due to corrosion: the engine was recently overhauled and looks quite fresh everywhere except the gears, and then only the higher-stressed ones. We routinely see this kind of pitting on heavily stressed engines (towing, aerobatics) rather than on hangar queens.

It looks to me like classic gear tooth surface pitting that results from use, fatigue of the surface, and not from impact or corrosion. Having said that, photos can be deceptive.

Silvaire wrote:

Thanks for posting info on the LOM engine, it’s interested me for some time, before and after reading articles such as this one.

“W-Motor” (actually W-Motor Service) in that article is us. G-BEWO, the aircraft described in the article, left our shop in September last year, and bears my fingerprints as well  The engine in it, however, belongs to the previous generation, Walter Minor 6-III, which is an OHV engine as opposed to M137’s OHC design. OHV is considerably less labour-intensive to overhaul and a bit sturdier.

The engine in it, however, belongs to the previous generation, Walter Minor 6-III, which is an OHV engine as opposed to M137’s OHC design. OHV is considerably less labour-intensive to overhaul and a bit sturdier.