I think your are taking a risk if the valve is showing green on the side and trying to resolve it with lapping. The exhaust valve can be that far deteriorated by overheating that a valve break is potentially possible.. I didn’t want to take that risk knowing I am quite often in IMC…Opinions may vary ….The cylinder was out of spec to rebuild it anyway

Vref wrote:

I think your are taking a risk if the valve is showing green on the side and trying to resolve it with lapping. The exhaust valve can be that far deteriorated by overheating that a valve break is potentially possible.. I didn’t want to take that risk knowing I am quite often in IMC…Opinions may vary ….The cylinder was out of spec to rebuild it anyway

Absolutely correct – apologies if my post seemed to question your decision – not my intention although it’s clear after re-reading my post that it sounds that way.

BTW, another good podcast that talks about GA aircraft maintenance issues is this one: https://www.aopa.org/news-and-media/podcasts/podcasts/ask-the-a-and-ps

Peter wrote:

Well, yes, that pretty well describes the aircraft maintenance scene generallyNobody has a monopoly on illiteracy so a lot of stuff gets done by following “the simple route” which may financially disadvantage the client but minimises the risk of a comeback on the engine shop, whereas “cylinder work” would expose the shop to client unhappiness if they do a bad repair.

You hit the nail on the head @Peter

This is not however a spontaneous result but a result of customer demand.

There are fewer and fewer good GA engineers. When customers demand tight prices, there is no room to make up for the risk (to the shop) of doing cylinder lapping work and then having the customer return 50 hrs later with a cylinder problem and asking the shop to fix it in warranty: shops need to make a living.

Replacing the cylinder may be five times the cost but facilitates more enduring success and ensures you get the OEM or the cylinder shop’s warranty, so your aircraft shop is not so much on the hook.

There are still good engineers around, but they are hard to come by and tend to discriminate between types of customers and associated work too.

Aircraft cylinder overhaul shops used to make a lot of money, say 30 years ago, but today the cost of new cylinders is so low they mostly went of business. $1250 or less for an O-320 cylinder with all new parts. Those engines were the bread and butter for overhaul shops once upon a time. Another contributing factor is crack growth, which doesn’t reset with overhaul. New Lycoming and Continental cylinders for common types of engine and aircraft are now a commodity item.

Several US airboat engine suppliers (including the infamous ‘Junior’ Jernigan in Plant City FL) do take half worn cylinders and overhaul them economically, but they have resources and equipment beyond that typically available to aircraft engine shops, reducing labor, and no paperwork. Notwithstanding the cylinder overhaul situation there is an underworld of suppliers in the engine business, and most of them aren’t on the web. When Barrett is looking for a rare part, guess where they go?

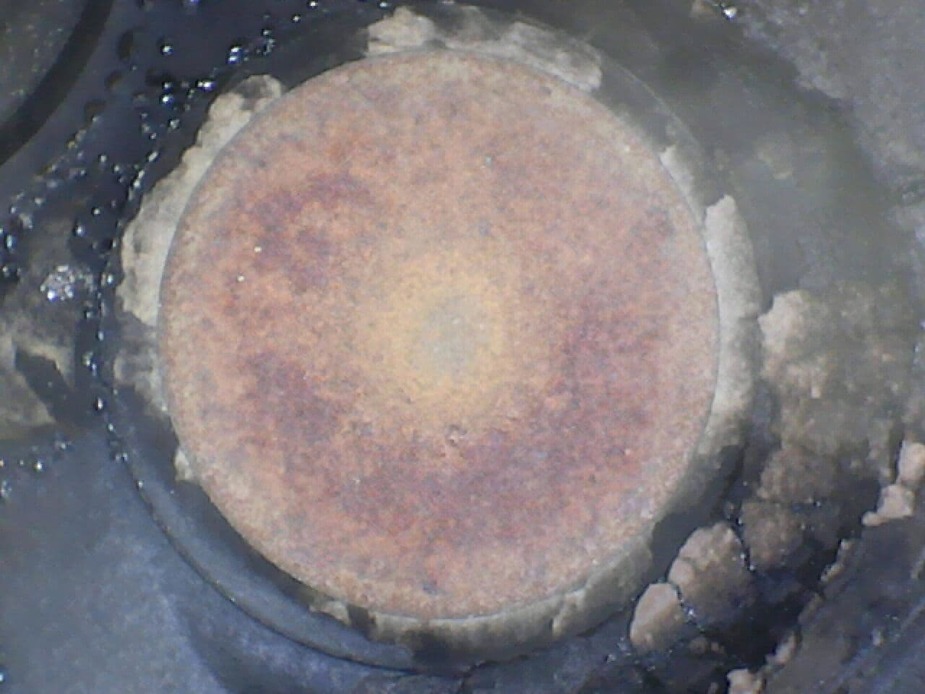

It is weird how differently the six exhaust valves can look:

I agree. I borescope at least every 50 hours, sometimes every oil change (25 hours) and it’s amazing the variation. My last lot (of 4 valves) vary as much as yours.

Another set of photos. In order 1-6, and inlet and exhaust valve for each:

Well, either nobody here borescopes their valves, or they get somebody to do it who never shows them the photos

It’s same with cutting open oil filters.

I would boroscope mine if it she would not sit in Tarbes :). When she comes back, I will do a fresh boroscope. I still have 2 weeks before the delivery flight at least. They had to replace the frame Nr6 baggage compartment wall…for 5000EUR (1500+3500 labour)