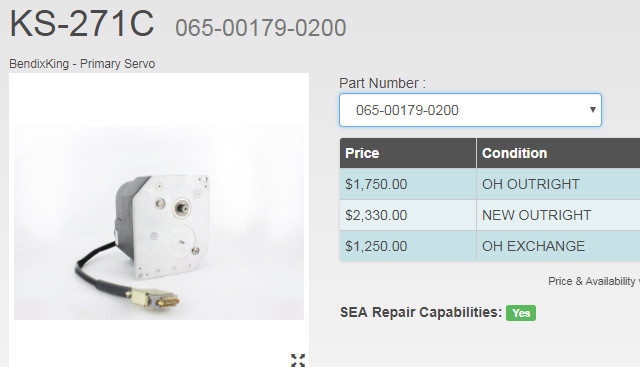

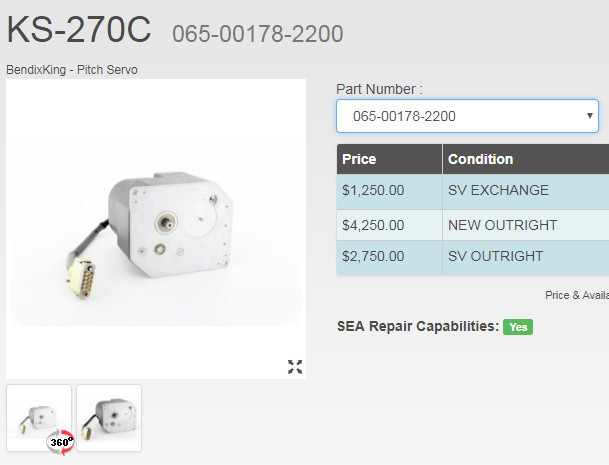

Some example prices, from here:

Roll servo:

Pitch servo:

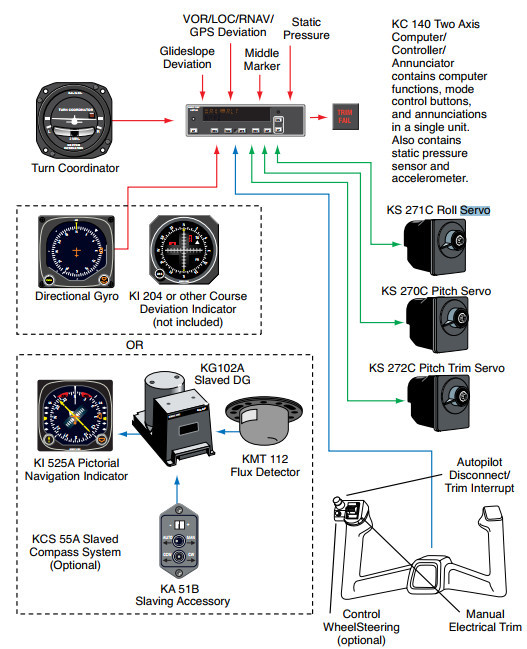

Interesting this suggests that the KAP140 uses the same servo (maybe not the same suffix) as the KFC225

These servos are easy to bench test. They have a control voltage from -9V to +9V. The above comments about startup voltage are irrelevant to these because they contain internal tacho feedback, so you get a linear voltage → RPM relationship, from close to 0V to 9V. Unfortunately this also means that a shagged motor is concealed until it is well gone.

Airborne_Again wrote:

Did you manage to make your own cable? I couldn’t find any info about the plug or wiring in the MM.

Yes.

The cable is the same as Peter has described. As per wigglyamp’ post the plug is near the hand brake.

pmh wrote:

The cable is the same as Peter has described.

I found the docs now, thanks!

I want to give it another go and try to measure the voltage reaching the connector before the servo when forcing an output from the PC.

Is it correct that +9v to – 9v shall be measured between

D – COMMAND REF

and

L – COMMAND

and the measured voltage shall be linear in respect of the output setting between -1 and 1 on the PC?

pmh, you might want to get a hold of Martin Scheifl, at Avionik Straubing, EDMS.

He’s about the most knowledgeable guy I know about autopilots. We had a problem with our KFC150 servo once; while two other avionics guys were guessing around and wasting our time, Martin found the reason real quick. You might want to try to call him and see what he suggests.

Just my two cents.

Today we had the PC connected to the KAP140 again.

We first verified the 28V and found that OK.

Then we measured between CMD and CMD GROUND

Forcing varying outputs with the PC we measured between -11 and + 11 V

As I understand that should have been -9 to +9 V, anyway the motor did not move at all.

We are going to order an exchange servo and get that fitted.

Today we had the exchange roll servo installed.

Now the autopilot is working again.

It was already clear when the old came out that the shaft was free wheeling. We did not open it but definitely some mechanical failure.

Now we hope it is accepted in return so we only have to pay the exchange fee.

I’ve also checked our broken autopilot using a PC. It turns out that while the roll servo clutch works, the ailerons don’t move when you give a command to the roll servo motor.

So it looks like the servo motor or its driving electronics are broken. What confuses me a bit though, is that the “valid” output from the roll servo remains true. I would have thought that if the servo tachometer doesn’t register any movement, this output would be false. So it could be a mechanical problem?

@Peter, would you have any idea? The KAP 140 uses the same roll servo as your KFC 225.

See here

The “valid” output from these servos is a fake signal. It is derived from the amplifier output, only, and is thus valid even if the motor is burnt out. All it checks is that the amplifier output is the right polarity

I don’t think you can buy the motor assembly alone. I tried but failed. It is listed on the usual aircraft parts dealer websites but none of them had it in stock when I looked; they just list every possible P/N in the hope of getting an enquiry. The motor can be rewound, with some difficulty, by any motor repair shop; see my notes. Obviously it can be done only off the books; you won’t get a certified repair unless you send the servo to Honeywell.