Stephan_Schwab wrote:

Having the TAT system means I simply use a certain fuel-flow (16 GAL/hr) and RPM value (2500) and that’s it.

This setting is the same as in my Turbo Skylane with Lycoming IO540, MP 25, RPM 2500, FF 16 G/hr, TIT never exceed 1630 F°.

Full Power is MP 32, RPM 2800, FF 24 G/hr- I need this setting only for two minutes.

And you probably want to check the spark plug on the opposite plug on cylinder 5, as it should have performed like the others if on one mag?

Yes. They said they will do that

Stephan_Schwab wrote:

I just learned that my right-hand magneto had died. That caused insufficient fuel burn and thus high temperatures

NAILED IT !

What do I win ?

ps: I doubled down if they were Slick pressurized – so are they ?

I just learned that my right-hand magneto had died. That caused insufficient fuel burn and thus high temperatures Good to have two mags

I have had exactly the same 4 weeks ago. I made a replacement for both magnetos. Just to be sure, because both of them had been overhauled just 152 hours ago, and the right one was completely destroyed.

I wonder which shop overhauled them.

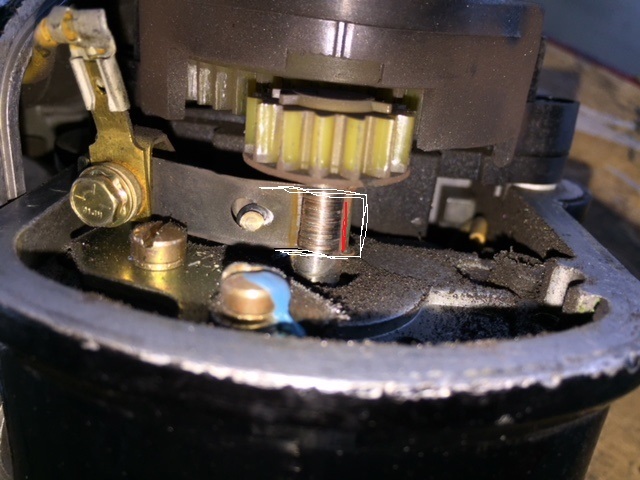

What do you mean with “completely destroyed” ?

That‘s what I mean.

This may be why an overhaul is better than an “inspection” because in an OH you change all these parts.