greg_mp wrote:

Modern electronic injection ensure that all that is injected get into the cylinder at the moment it is injected, and direct injection is one step farther, whereas carbureted cylinder do vacuum an air-petrol mixture from an oscillating airflow, where there are big and small droplet of it, some of them going on the wall. Bigger droplets incorrectly burnt…

I spent a lot of time working on manufacturer-installed EFI for motorcycles and sold a product related to that work for about 20 years continuously. EFI makes cold start a lot better if that’s a consideration (and it often is, on a highly tuned engine) and it tolerates alcohol in fuel better (which is important unless you have real gasoline) but there was no improvement in fuel efficiency, because the previous carb’d models with otherwise identical engines had a carb for every cylinder – which works very well. There are many examples where EFI on motorcycles is less efficient than the carbs it directly replaced, because the EFI mapping is not as good as nature provided with the carb. This situation has improved over the years, but fuel efficiency is still no better than it was in 1990, with carbs. Why then do motorcycle manufacturers utilize EFI? Because they can tune a small region of the fuel maps to pass emissions tests, while not affecting the rest of the operating regime like you would when tuning carbs to pass emission tests. It’s generally nothing to do with efficiency, assuming you would otherwise have a carb for every cylinder.

Direct injection has particulate emission problems (maybe not a problem on an aircraft engine) and very high pressure fuel lines which would not be a good thing under the cowling. Nobody uses it on gasoline aircraft engines for that reason.

The real world advantage of fuel injection for an aircraft engine is related to individual metering of fuel to each cylinder. That provides maybe a 5-10% improvement in efficiency because you can run lean of peak EGT in cruise. However it also adds complexity and/or hot start issues and on my plane I’m happier to have a single carb that just works, and keeps working. The additional $4/hour in fuel cost for my little 150 HP engine is not important to me by comparison – I pay $100 in hangar cost or more for every hour I fly. It may be important on larger engines, on planes flown a great deal and planes flown for very long legs, but there is a concept called appropriate technology that means something to me and to the maintenance of my plane, and equally to many other people. More is not always better

Peter wrote:

The slow progress of electronic ignition is a curious thing.

What’s wrong with this

greg_mp wrote:

Actually Edge performance (rotax tuner and provider) do make a ket with additional generator for its injection kit, that can be a small 15a or a big one, and provide 2 pumps. Much better than the DA40 CD135 engine that has only 1 HP pump and 1 common rail – and it is known to be safe.

It’s not a one to one comparison. The pump(s) in a gasoline injection like Rotax/Edge/ULPower are electric powered. The high pressure diesel pump is powered mechanically from the engine (it might have an additional low pressure electric supply pump). The common rail is just a dead piece of thick walled pipe.

Silvaire wrote:

Notice that the composite ground adjustable props for UL Power engines up to 130 HP are all substantially larger in diameter than 53 inches for efficiency, but thereby more highly stressed

70 inches is just way too large for the Onex. It’s generally very large in general. A STOL prop?

My Luscombe had a 74 inch diameter FP propeller for 65 HP. Note that the Whirlwind CS props for four cylinder 150-210 HP Lycomings on RVs are about 71 inches in diameter.

The Onex is designed around a small diameter prop because it was originally designed for a VW engine, which typically makes rated power at 3400 RPM.

Another reason might be that the Onex (make no mistake, if it wasn’t for my, and my friend’s wive, we might have started building a couple of Waiex, which I still find cute) is one those, citing Peter smaller, simpler, less well equipped, etc, and a smaller cockpit will need less fuel for a given speed. affair

Silvaire wrote:

but there was no improvement in fuel efficiency

In the theory, this is gasoline with air, and the theoretical efficiency cannot improve if you don’t change the type of cycle or the compression ratio.

But carburettor cannot adapt the fuel, it only provide a quantity based on pressure difference and air flow speed. And yes, you could have good working carburettor on each cylinder with very efficient plenum and induction system, but you will only address full power, you will never have the possibility to tune the A/F ratio.

So no, it cannot be better than an injection system on the same level of refinement, and god know that you need a carburetor wizard to make a 4 Weber-engine working. How many wizard in aviation?

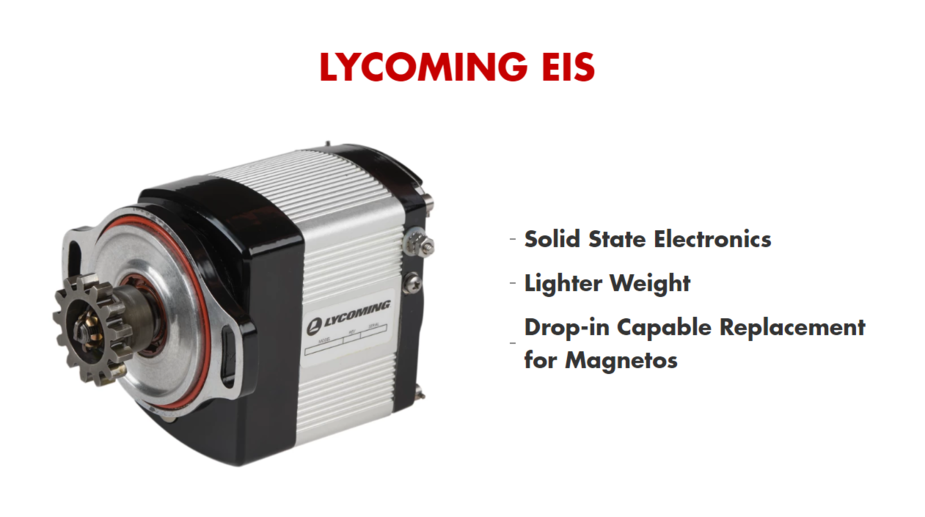

Yes; the EIS is one product but it won’t run without your aircraft power supply. It is not a self powered standalone magneto. Such a product is certainly possible to design but for some reason nobody has done it.

Silvaire wrote:

which typically makes rated power at 3400 RPM

Or more  I remember I looked at some other props. Sensenich has one (special made for Sonex for UL350, wooden fixed pitch). They do however also have a ground adjustable carbon type for UL350, with a diameter of 60-64 inch. Duc Helices makes very good propellers (all carbon, adjustable), probably the best there is. If I ever brake my Prince prop, I would probably go for Duc, rated at 3400 rpm for the direct drive ones. We have one on the club’s Pipistrel, a huge jump in performance compared with the original prop, and have only heard similar stories.

I remember I looked at some other props. Sensenich has one (special made for Sonex for UL350, wooden fixed pitch). They do however also have a ground adjustable carbon type for UL350, with a diameter of 60-64 inch. Duc Helices makes very good propellers (all carbon, adjustable), probably the best there is. If I ever brake my Prince prop, I would probably go for Duc, rated at 3400 rpm for the direct drive ones. We have one on the club’s Pipistrel, a huge jump in performance compared with the original prop, and have only heard similar stories.

Anyway, there is no problem finding props with higher than 2800 rpm, except perhaps for constant speed. This is a bit chicken and egg kind of problem due to existing “as is” rather than engineering/physics.

Peter wrote:

Such a product is certainly possible to design but for some reason nobody has done it.

Yep, we had this already in another thread…

Well, the non-certified (poor you certified stuff owners  ) P-mags/E-mags gives variable timing, electric or independent operation. And are the easiest EI system to retrofit and replace those antique mags. All reasons of their success in the homebuilt market.

) P-mags/E-mags gives variable timing, electric or independent operation. And are the easiest EI system to retrofit and replace those antique mags. All reasons of their success in the homebuilt market.

Peter wrote:

Such a product is certainly possible to design but for some reason nobody has done it.

This has existed for decades. Completely stand-alone, but never certified. Redundancy vise this is a complete hole in the head, since one failure mode is too advanced timing that will destroy the engine within seconds rather than minutes. A Rutan canard of some kind crashed here in Norway due to this, 15 years ago perhaps. The only way to fix this, is two units that are not standalone devices, either by simple external monitoring, or by checking each other.