The engine has been around for almost 10 years. I think it is not an unsafe bet. If we always want to only rely on what is proven, we’d be riding horses in 1000 years from now

It is a very sturdy design with good failsafe characteristics but of course very expensive because it is all made from custom parts. With 260hp, it’s a highly attractive package. The upcoming 6 cylinder version is also interesting.

In the 155hp field, Continental/Thielert have a fantastic engine and I don’t see anybody having a chance to compete in the foreseeable future. In the Lycoming/Conti 6-cylinder replacement business (in which the SMA 230/260 plays), it’s still not clear who will win. Thielert with a V6 Mercedes or SMA.

The engine has been around for many years, but how many airplanes have been equipped and how many hours have they flown?

I personally know one guy who crashed in a SMA retrofit C182 following an engine failure. I concede that’s only one data point, but the early Thielert issues make me cautious about new engines.

I believe the 260 HP SMA that equips the new DA50 is a new design and completely unproven.

The 260hp SMA engine is essentially the same engine with a bit bigger cylinders and even more turbo oomph.

As far as I know, about 50 engines have been built so far. I wouldn’t say that Thielert was particularly troublesome, there was one major design flaw (the clutch) and the meltdown of the company. Other than that, it has been great technology and workmanship from the beginning and with moderate investment has resulted in a very small 155hp engine with a TBR of 2100h, exceeding all common AVGAS engines. Thielert engines have never had a documented in-flight shutdown rate that was higher than the 1940s stuff we depend on and today their failure rate is considered to be significantly lower than industry average. I think Continental got a good deal and the Thielert investors did something good by donating their money. The cycle innovator → inflated expectations to get money → bust → pennies for the dollar → success is pretty common actually.

The technically much less ambitious Austro version of the same base engine as Thielert didn’t have a lot of teething problems but apart from being less complex, it also benefited from the lessons learned.

I would say that the SMA engine is a solid and sufficiently proven design by now. The biggest question is the long term viability of the company. This is more a question of them wanting to do it because SAFRAN is a typical French-government-unlimited-resources company.

The Thielert 172 (now a standard Cessna product from the factory production line) has a guaranteed market in training outside the Western world, the 182 is different so I don’t know how successful they will be. However, I do think that an STC makes more sense than offering it as a factory new option, which Cessna considered for some time.

There is also https://eps.aero/is-your-aircraft-an-stc-candidate/

I think it’s refreshing to see designs that do not consider the power producing part (e.g. the cylinder) as a consumable with a random life expectancy.

I don’t think EPS will succeed. Diesel engines are heavy due to the high combustion pressure and only through very high manifold pressure they can compete. A 4 cylinder diesel has to be geared to compete with a 4 cylinder AVGAS (Thielert) and a direct drive diesel with 4 cylinders competes with 6 cylinder AVGAS. That doesn’t really leave room for a 8 cylinder direct drive diesel, it is too heavy and large for the airframes out there. If they get it to power significantly above what AVGAS engines deliver (i.e. > 400hp), the question of suitable airframes still remains. The car industry has mostly moved away from V8 diesels in the 400hp power range as well. The current Mercedes OM 656 (probably the most advanced diesel engine out there) is currently in production with 340hp but more will come — at 3000cc (modern engines all use 500cc cylinders).

I wouldn’t say that Thielert was particularly troublesome, there was one major design flaw (the clutch) and the meltdown of the company

There was a little more than that. High- and low-pressure pumps broke down due to lack of lubrication. Electrical issues with the ECUs called for a backup battery. There were some ECU failure modes that caused the engine to shut down.

It is all behind us now, but it earned the engine a very bad reputation that still sticks today although it now seems to have a better shutdown rate than the AVGAS counterparts.

The problems you mentioned were rather small on a technical level. Quite easy to fix, requiring small refinements only. AVGAS engines have problems, too — see Lycoming conrod bushings right now, crankshafts before, etc. I can assure you that e.g. in boating it is much worse, you wouldn’t believe what kind of immature cr*p Volvo dares to charge money for…

For some reason pilots are OK with Lycoming and Conti selling terrible products but the newcomers are held to the highest standards.

I would hope EPS did the weight math before starting out – if it really were that heavy it would throw the whole plane out of balance, no?

With regards to Thielert vs LyConti – Thielert fixed their problems in ten years, now have an (almost) flawless product.

LyConti have been delivering engines with the same unfixed design & production problems for 50 years+ .

but the newcomers are held to the highest standards.

One factor is the lack of field overhaul/repair options on the European engines, which puts the owners over a barrel.

Shorrick_Mk2 wrote:

I would hope EPS did the weight math before starting out – if it really were that heavy it would throw the whole plane out of balance, no?

You would be surprised how many projects just start as wishful thinking, get some money, promise everything and then see how far you get. I do not think there is a market for a 8 cylinder diesel. It needs more space and has more weight than any existing engine it could replace. Also you do not need 8 cylinders for 300-380hp, that’s not state of the art. There is even a 8 cylinder Lycoming…

Peter wrote:

One factor is the lack of field overhaul/repair options on the European engines, which puts the owners over a barrel.

Which barrel? Thielert replacements and Austro replacements are very comparable in cost to Lycoming. If it becomes too expensive, the engines become less attractive and they sell less. As technology evolves, complexity increases and field maintenance becomes more difficult. That is quite normal and I do not think that the right answer is to carry on with the 1940s stuff. The diesel engine makers have enough reason to ensure good and fair repair options.

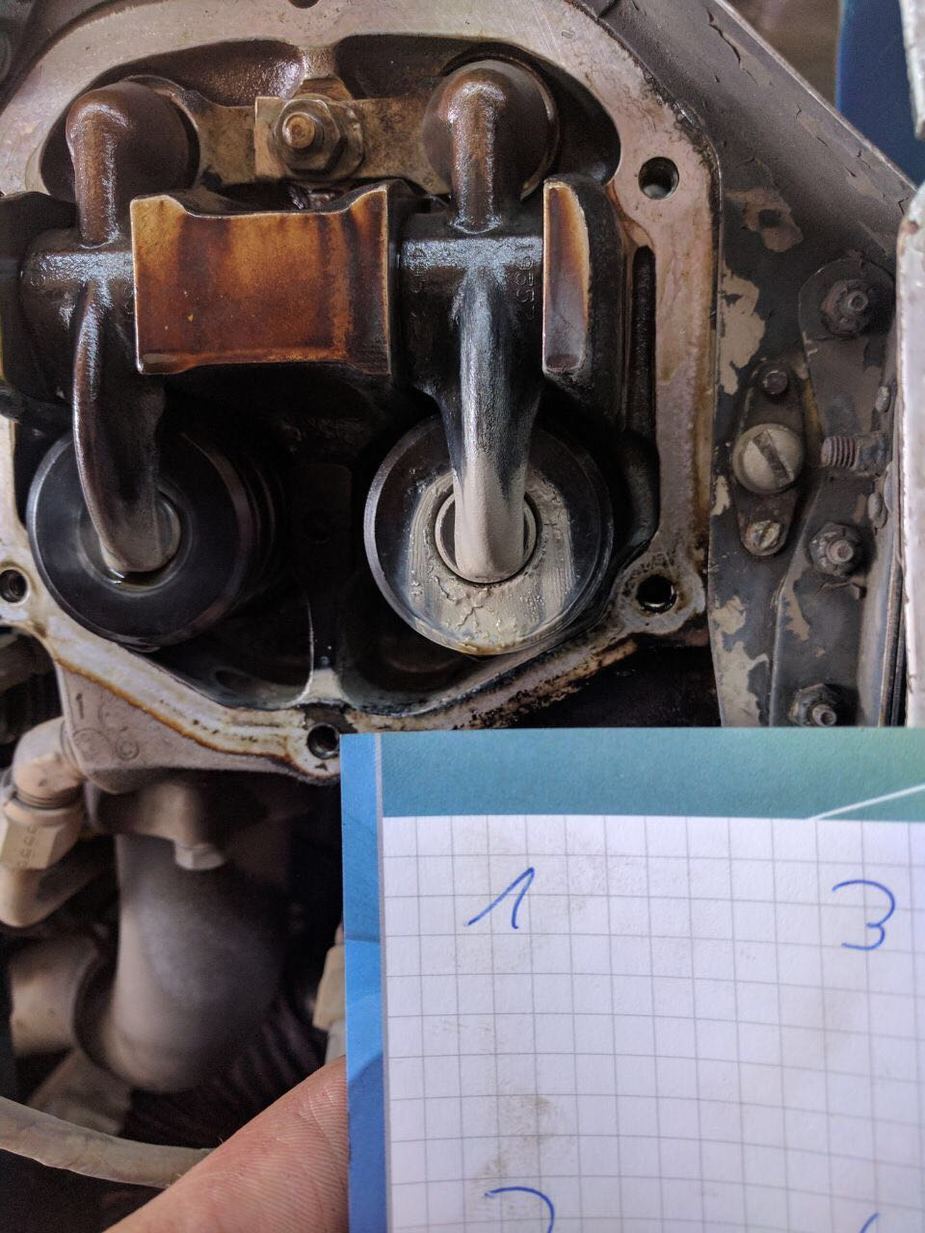

I just got this from a friend with a 1600h/9year Lycoming 540: