Here’s a nice video showing some PA 28 internals incl. wing removal/installation.

By9468840 wrote:

are the push/pull cable conduits for the main landing gear

Ah ok understood. I haven’t had the opportunity to see this perspective, and it’s always good to understand how things work.

P.S.: Sorry for off-topic!

UdoR wrote:

What are those hoses coming from the wings?

what you see in the picture are the fuel lines from the wings and below them are the push/pull cable conduits for the main landing gear.

I think the PA24 spar arrangement is quite brilliant. It is one reason for the spacious cabin, looking at how small it is from outside.

@By9468840 What are those hoses coming from the wings? Brake fluid or fuel? It is fuel, isn’t it? And the brake fluid runs through the thinner tube further down and farther back, right?

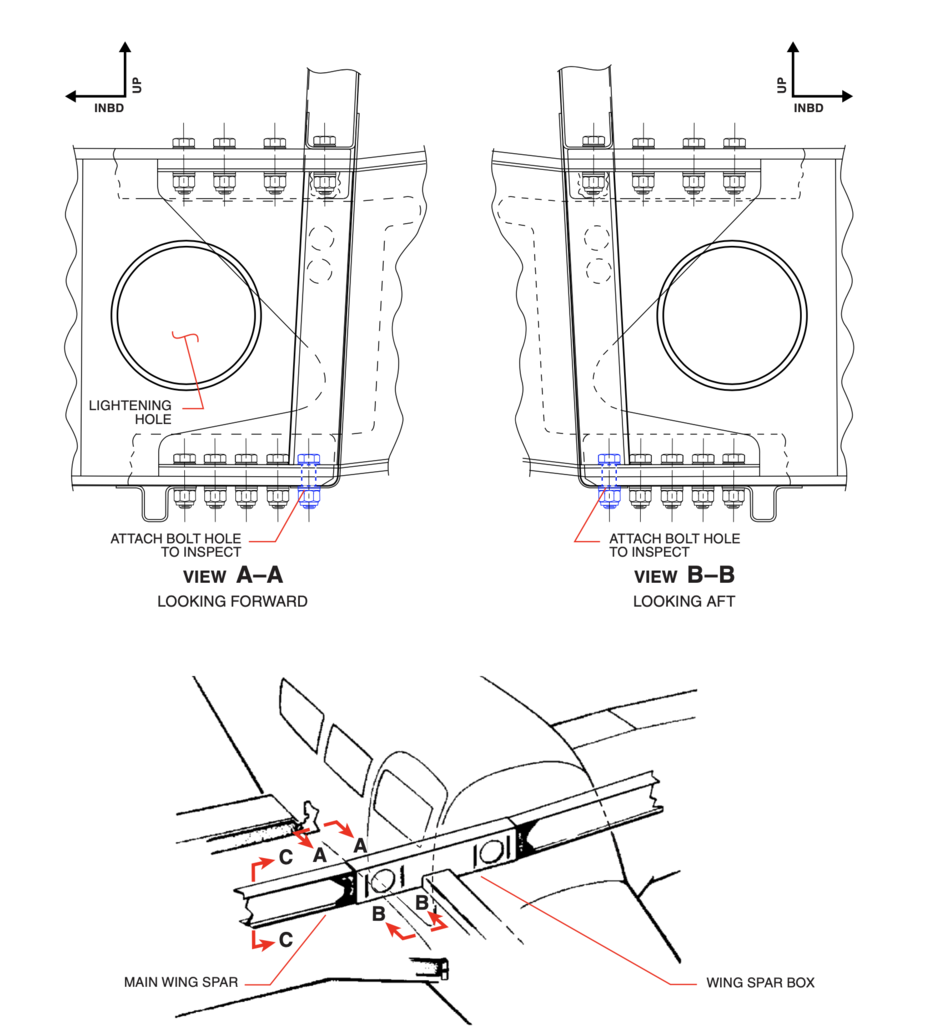

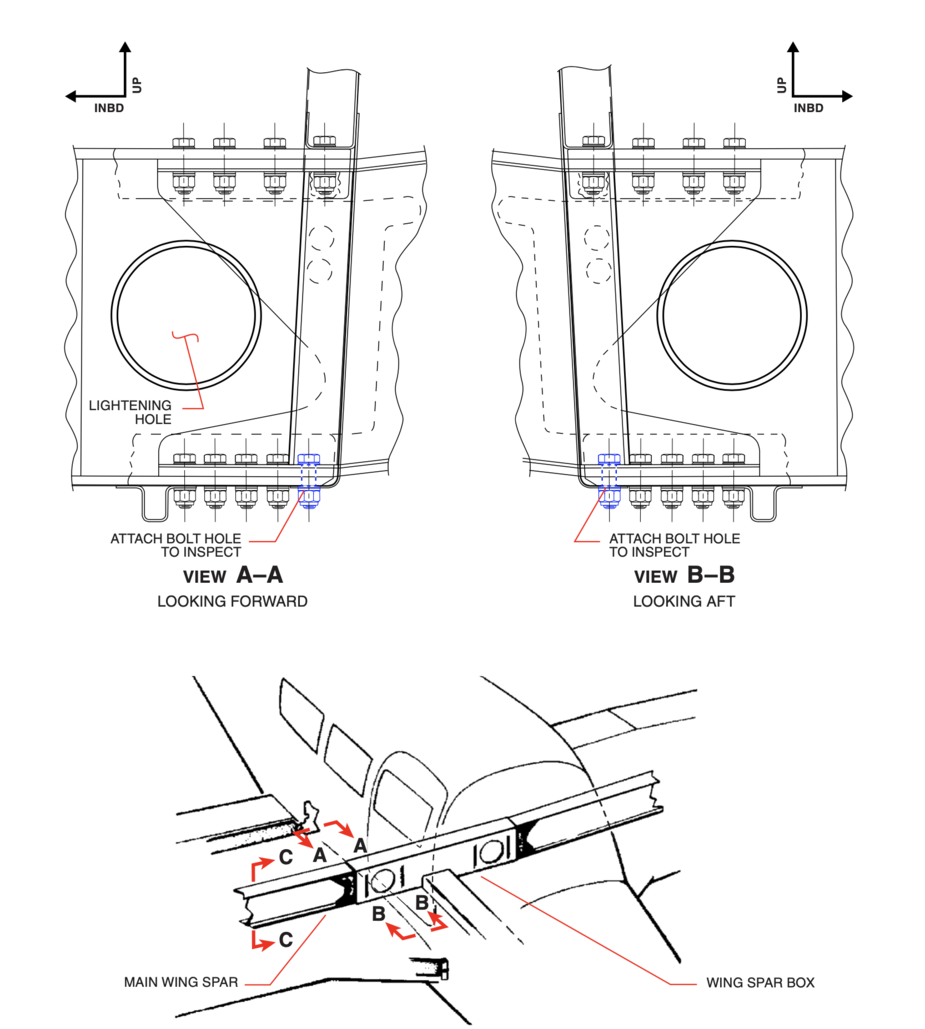

Just adding a picture of the PA24 Comanche spar to the collection for debate. The structure is very noticeably thicker than the PA28 type but also keep in mind PA24 type certificate has engines up to 400hp IO720. What I find interesting however is that the PA24 spars are joint in the middle of the cockpit and the fuselage is mounted ON it via several mounting locations vs PA28 spars being mounted on the sides of the fuselage in a carry through structure. Not being a structural expert, I can only assume that the vertical bending forces on the spar is distributed over a larger area in PA24 than it is on PA28 which is essentially distributed over the spar bolts on each side.

I still don’t mean though PA28 structure is weak. It is just different and PA24 seems more obvious to be designed to carry larger loads due to aircraft being heavier, larger and it is type certificated to carry a 400hp engine cruising at 190 ktas. I think the general risk of structural failure on a PA28 is largely associated with it’s wide use as trainer and the difficulty in inspection of the spar attachments. I would generally avoid buying any a high airframe time, high cycle trainer aircraft. PA28 or not.

Worth noting I suppose that the wings on a Bonanza are held on with two bolts each.

Seems sturdy. Wings stayed on.

VS.

The wing spar attach points on PA28 series aircraft (and indeed all the aircraft based on that design) do “look” less substantial than on some other aircraft.

Worth noting I suppose that the wings on a Bonanza are held on with two bolts each.

In flight breakups are not necessarily wing spar failure either, I don’t know why everyone keeps talking about the spar only. You can have flutter leading to failure of empennage components, for example. Stabilator attachments on PA28 and TB20 look surprisingly fragile given the job they carry out.

I did look into the PA28 wing spar failures and whilst I do believe it’s less strong than some other designs, all of the aircraft which had failures in normal flight regimes are aircraft which have had very hard lives.

Finally I’d add that the PA28 fleet now probably has very few, if any, aircraft with defective spars following the inspection ADs.

I wonder if the outermost bolt hole is the weak point because the hole obviously removes material. Why not move the spar (C) futher inboard and fasten it there, leaving more material at the area of greatest bending moment?

TB20 spar is not one piece from wingtip to wingtip.

2 or 3 have broken up in TS.

As far as I remember the design is such that only one of several bolts carries the load, or most of the load. The bolt itself is OK, but not the structure around it because that structure is designed with friction in mind. With a perfect fit, the right amount of torque, no corrosion, it probably will be OK and will last for ever. But too much torque will insert too much stress on the structure around the bolt. Too little torque will weaken the friction between the members so too much load is applied to the bolt and the structure around it. A less than perfect fit will weaken it considerably, which could be problematic when changing a wing for instance, unless this is done 100% correct. Also, the condition and fit of the aft spar matters.

It really is an odd design that demands perfection in production and fit. What holds it together is not the bolts, but friction due to the torque of the bolts (which is a normal way of bolting stuff together, works for propellers for instance, but not the way it is done here, due to asymmetric/uneven load). The typical way to design this is to assure all the forces go through one single bolt, one at the upper and one at the lower, or a series of bolts all taking equal load, either pure shear or pure tension.

Another way to look at it, is it would be OK if the bolts worked as pure shear bolts (un-torqued), and the surrounding material allowed for this kind of load. Then it would be obvious that only one bolt (two) was needed.